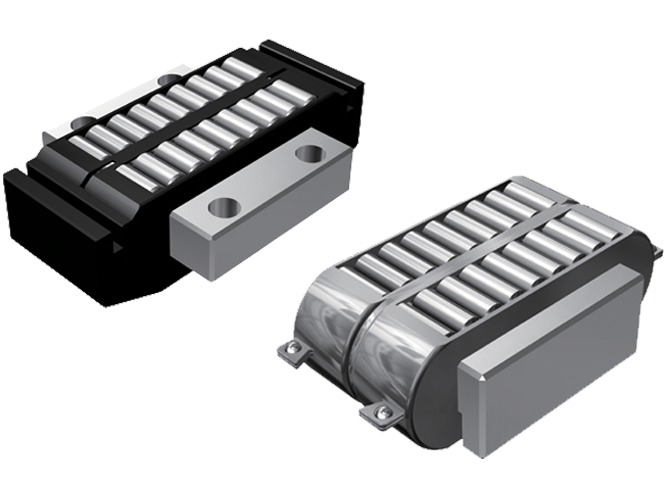

LM Roller

In the LM roller, contoured rollers assembled on the circumference of the precision-ground, rigid raceway base travel in infinite circulation while being held by a cage. A center guide integrated with the raceway base is formed in the central part of the loaded area of the raceway base to constantly correct skewing of the rollers. This unique structure ensures smooth rolling motion. The LM Roller is used in applications such as the XYZ guide of NC machine tools, precision press ram guides, press die changers, and heavy-load transfer systems.

Types

Highlight feature tags

- High accuracy

- Prevention of rollers from skewing

- Ultra-heavy loads

- High accuracy

- Ultra-heavy loads

- Prevention of rollers from skewing

- High accuracy

- Ultra-heavy loads

- Prevention of rollers from skewing

- High accuracy

- Ultra-heavy loads

- Prevention of rollers from skewing

- High accuracy

- Ultra-heavy loads

- Prevention of rollers from skewing

Features

Structure and Features

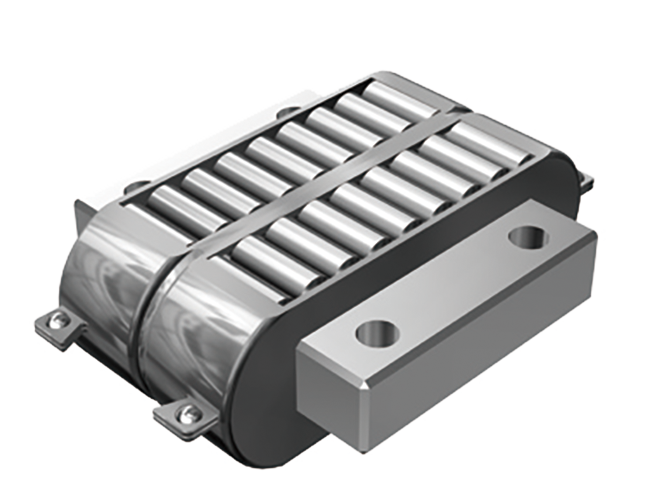

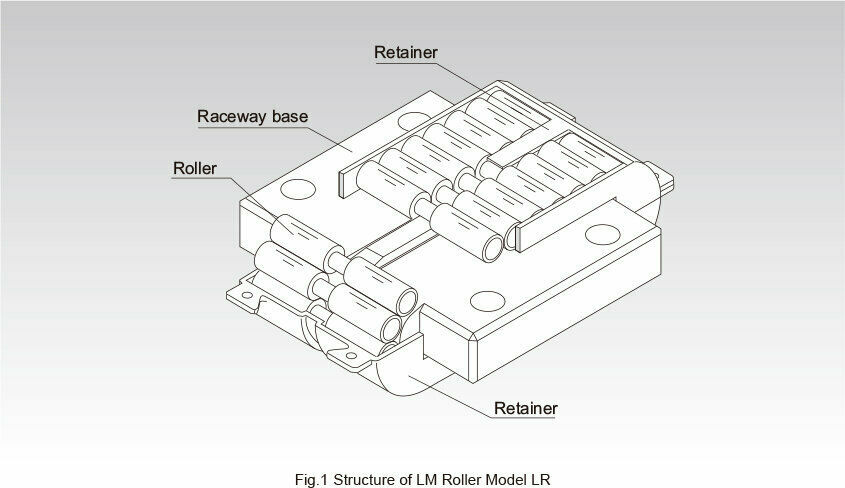

In the LM Roller, dual rollers assembled on the circumference of the precision-ground, rigid raceway base travel in infinite circulation while being held by a retainer. A center guide integrated with the raceway base is formed in the central part of the loaded area of the raceway base to constantly correct skewing of the rollers. This unique structure ensures smooth rolling motion. The LM Roller is used in applications such as the XYZ guide of NC machine tools, precision press ram guides, press dies changers and heavy-load conveyance systems.

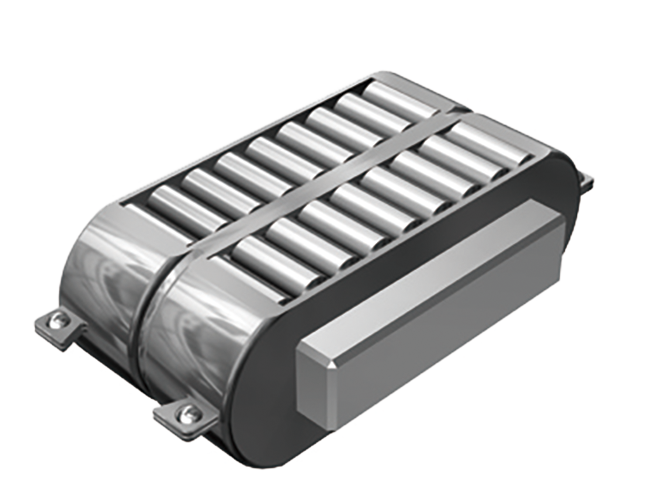

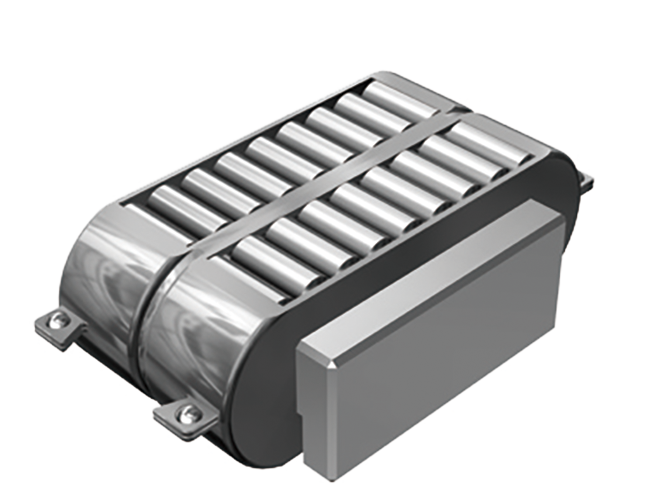

Supports an Ultra Heavy Load and Ensures Smooth Motion

The LM Roller is compact and capable of carrying a heavy load, and one unit of model LR50130 (length: 130 mm; width: 82 mm; height: 42 mm) is capable of receiving a 255 kN load. Moreover, because of rolling motion, this model has a low friction coefficient (μ= 0.005 to 0.01) and is free from stick-slip, thus achieving highly accurate straight motion.

High Combined Accuracy

In general, when supporting a single plane with LM rollers, multiple units of LM rollers are combined on the same plane, and therefore, the height difference between the rollers significantly affects the machine accuracy and service life. With THK LM Roller, the user can select a combination of models with a height difference of up to 2μm.

Rational Skewing-preventing Structure

With an LM system using rollers, once the rollers skew, it increases friction resistance or decreases running accuracy. To prevent skewing, the LM Roller has roller guides on the center of the retainer full circle, and in the center of the loaded area on the raceway base. This structure enables the LM Roller to automatically correct skewing caused by a mounting accuracy error and the rollers to travel in an orderly manner. It also allows the LM Roller to be installed with slant mount or wall mount while demonstrating high performance.