LM Stroke Model ST

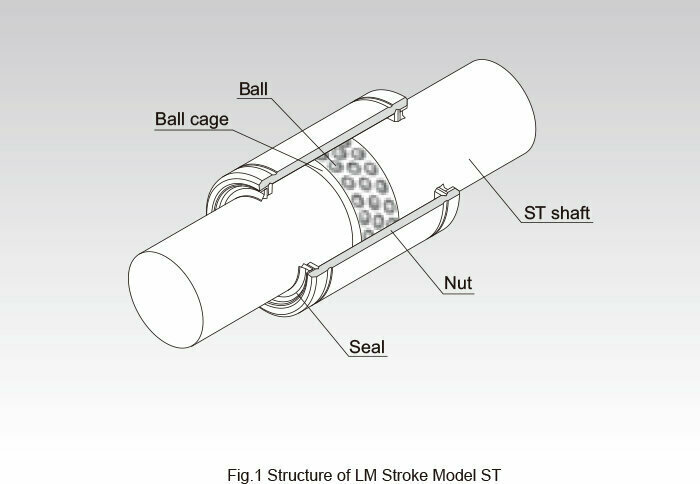

Model ST has a ball cage and balls both incorporated into a precision-ground cylindrical nut. The balls are arranged in zigzags so as to evenly receive a load. The ball cage is a drilled cage made of a light alloy with high rigidity, and is capable of high-speed motion. A thrust ring and a snap ring are installed on both sides of the inner surface of the nut to prevent the ball cage from overshooting.

Shaft Diameter (mm) : 6,8,10,12,16,20,25,30,35,40,45,50,55,60,70,80,90,100

Types

Highlight feature tags

- High accuracy

- Low friction (other linear motion guides)

- High accuracy

- Low friction (other linear motion guides)

Basic load rating kN : Basic dynamic load rating 0.98 to 22 / Basic static load rating 0.23 to 18.3

Shaft Diameter (mm) :

6,8,10,12,16,20,25,30,35,40,45,50,55,60,70,80,90,100

- High accuracy

- Low friction (other linear motion guides)

Basic load rating kN : Basic dynamic load rating 2.06 to 43.9 / Basic static load rating 0.55 to 36.8

Shaft Diameter (mm) :

8,10,12,16,20,25,30,35,40,45,50,55,60,70,80,90,100

- High accuracy

- Low friction (other linear motion guides)

Basic load rating kN : Basic dynamic load rating 0.98 to 22 / Basic static load rating 0.27 to 18.3

Shaft Diameter (mm) :

8,10,12,16,20,25,30,35,40,45,50,55,60,70,80,90,100

- High accuracy

- Low friction (other linear motion guides)

Basic load rating kN : Basic dynamic load rating 8.33 to 43.9 / Basic static load rating 3.24 to 36.8

Shaft Diameter (mm) :

20,25,30,35,40,45,50,55,60,70,80,90,100

Features

Structure and Features

Model ST has a ball cage and balls both incorporated into a precision-ground cylindrical nut as shown in Fig.1 . The balls are arranged in zigzags so as to evenly receive a load. The ball cage is a drilled cage made of a light alloy with high rigidity, and is capable of high-speed motion. A thrust ring and a snap ring are installed on both sides of the inner surface of the nut to prevent the ball cage from overshooting. This structure allows rotational motion, reciprocal motion and complex motion with a small friction coefficient. Model ST has a stroke length up to twice the range within which the ball cage can travel. Since high accuracy can be obtained at a low price, this model is used in a broad array of applications such as press die setting, ink roll unit of printing machine, workpiece chuck unit of punching press, press feeder, work head of electric discharge machine, wound roll corrector, spinning and weaving machine, distortion measuring equipment, spindle of optical measuring instrument, and photocopiers.

Minimal Friction Coefficient

The balls and the ball raceway are in point contact, which causes the smallest rolling loss, and the balls are individually retained in the ball cage. This allows the LM stroke to perform rolling motion at a minimal friction coefficient (μ=0.0006 to 0.0012).

Compact Design

Since it consists only of a thin nut and balls, the outer diameter of the bearing is minimized and a light, space-saving, compact design is achieved.

High Accuracy at a Low Price

A highly accurate slide unit can be produced at a low price.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Model Number Coding

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |