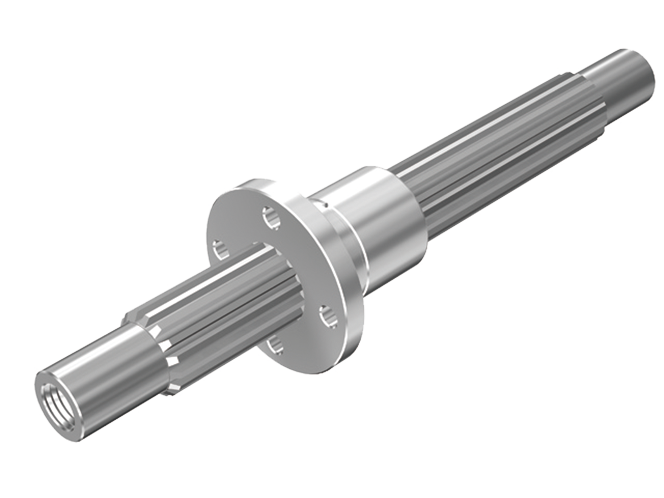

Spline Nut Models DPM and DP are low-price bearings that are made of a special alloy formed by die casting, and they use highly accurate spline shafts as the core. Unlike conventional machined spline nuts, the sliding surface of these models maintains a skin layer formed in the rolling process, thus achieving high wear resistance.

The surface of the spline shafts to be used in combination with the nuts is hardened through rolling and is mirror-finished. As a result, smooth sliding motion is achieved.

The specially designed teeth of the spline have large contact areas in addition to concentricity, which enables the shaft to automatically establish the center as a torque is applied. Therefore, the teeth demonstrate stable performance in transmitting torque.