Utility Slide Precautions on Use

Precautions on Using the Model UGR

Handling Precautions

- Do not disassemble the parts. This may result in debris entering the product and loss of functionality.

- If the slider is removed from the rail, balls will fall out. A stopper is installed to prevent the slider from coming off, but please exercise caution when handling.

- Tilting the slider or slide rail may cause it to fall by its own weight.

- Take care not to drop or strike the utility slide. Otherwise, it may cause injury or damage the unit. Even if there is no outward indication of damage, a sudden impact could prevent the unit from functioning properly.

- Be aware that the permissible load of the utility slide will vary depending on direction.

- Prevent foreign materials from getting inside the product. Otherwise, it may damage the ball circulation components or result in a loss of functionality.

- If foreign materials adhere to the product, replenish the lubricant after washing the product.

- Do not subject this product to harsh conditions, such as an abnormally hot, cold, damp, or dusty environment, or to intense, repeated motion that would cause it to heat up due to friction. Use of this product under such conditions can result in damage or loss of functionality. Please contact THK if the product will be used in harsh conditions.

- If the utility slide will be used in an inverted orientation, take preventive measures such as adding a safety mechanism to prevent items from falling. If the slider is damaged due to an accident, etc., balls may fall out, or the slider may become detached from the slide rail and fall down.

Lubrication

A black lithium soap-based grease is applied to the slider and ball circulation components. Do not mix lubricants with different properties.

Storage

When storing the utility slide, pack it as designated by THK and store it indoors away from extreme heat or cold and high humidity.

Disposal

The product should be treated as industrial waste and disposed of appropriately.

Precautions on Using the Model ATG

Precautions on Use

- The outer member and inner member stoppers are not designed to handle impact loads. Be certain to provide external stoppers at the stroke ends.

- When installing this product, mount two slide rails on the wall as a set. Be certain to contact THK if you will be using only one slide rail or changing the mounting orientation to something other than what is indicated in the mounting orientation diagram.

- The greasing interval varies depending on the usage conditions and environment. Ultimately, the greasing interval and amount of grease applied should be set using the actual device or machine.

- Do not enter the movement range of moving parts while the device is operating or in an operable state. In particular, do not touch any moving parts during operation.

- Stop the machine (turn off the power) before moving, installing, or performing a maintenance inspection on this product.

- If performing an installation, maintenance inspection, or other task involving multiple people, confirm how to perform the work, what signals will be used, and how to handle problems before beginning, and assign another person to monitor the work.

- Do not place anything on this product or its packaging. Do not apply a strong impact to this product.

- Do not apply a load that exceeds the permissible load.

- Do not disassemble or alter this product.

- Securely fasten the product before use.

- If an abnormality occurs, stop the machine immediately.

- Do not use a product that is malfunctioning or broken.

- Avoid impacts when transferring objects.

- Contact THK if the product will be used in an environment outside of the specified temperature range.

- Ball cages may become misaligned due to factors such as machine vibration. To realign ball cages, remove any borne load, then fully open and close the product. During realignment, it will take more force to move because the balls will be sliding. Exceeding the stroke range may cause components to break.

- When installing the product, adjust the mounting so that the product runs steadily at a force of 15 N or less when not bearing a load.

Precautions on Using the Model Advanced Wheel Guide

Handling

- Tilting a carriage or outer member may cause it to fall by its own weight.

- Please use at least two people to move any product weighing 20 kg or more, or use a cart or another method of conveyance.

- Do not disassemble the parts. This may result in loss of functionality.

- Do not apply a load that exceeds the permissible load.

Use

- When installing this product, wall-mount two units facing each other. If mounting a single unit on its own, please prepare a steady brace.

If a mounting orientation other than the aforementioned is required, contact THK. - Placing a hand inside the outer member’s mounting holes may lead to the hand being caught between the carriage and outer member and cause injury.

- When using joint products, confirm that the sliding resistance o f the joint portion will not fluctuate before mounting.

- Do not apply an impact to the product when mounting. Doing so c an impair the function of wheels and other elements.

- Prevent foreign materials, such as cutting chips or coolant, from entering the product. Failure to do so could damage the product.

- Do not use the product at temperatures above 80°C. If used above this temperature, there is a risk that the resin and rubber parts may deform or become damaged.

- If particles, liquids, or other substances adhere to the product, replenish the lubricant after cleaning the product.

- Wear appropriate safety gear, such as protective gloves and safety shoes, when handling the product.

- Do not stand on this product or its packaging. Do not apply a strong impact to this product.

- If a stopper is added to prevent the carriage from coming off at the edge of the outer member, make sure that the stopper does not make contact with the carriage.

- If this product breaks due to an accident or other cause, the carriage may come off of the outer member and fall. For the safe use of this product, take precautions such as adding a mechanism to prevent carriages from falling. Please use a mechanism that is structured in a way that it does not touch the product directly, because if an impact load is applied to an end plate or grease nipple, it may break and cause a malfunction.

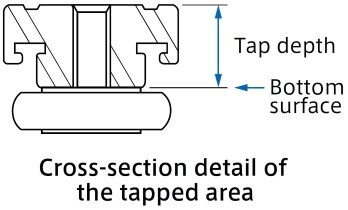

- For the carriage securing bolts, select a length that will leave some clearance between the tip of the bolt and the bottom of the tap hole so that the bolts don’t break through the lower surface of the hole. If the tip of a bolt breaks through the bottom surface of the tap hole, it can make contact with the wheels and damage them.

- If the mounting material lacks sufficient rigidity or accuracy, the bearing load will be concentrated at one location and performance will dramatically decrease. Therefore, carefully consider the rigidity and accuracy of the housing and base as well as the strength of the securing bolts.

- If the product will be used in a location with a lot of vibration, we recommend using a locking agent on the mounting screws.

- If significant sliding resistance occurs along the stroke, it may be a result of how rough the mounting surface is, so it may be necessary to reexamine its machining accuracy.

- If this product is used with a large displacement in the rollin g direction, it may not seal as well. If you want to improve its ability to form a seal, please conta ct THK.

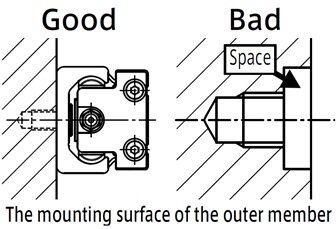

- If there are open spaces on the mounting surface for the outer member, the axial force of the screws may cause damage to the seating surface.Mount the outer member to a surface that does not have open spa ces.

- Use the Tightening Torque Table on this page when securing oute r members and carriages.

Tightening Torque Table

| Model No. | Screw size | Type of fastener used | Tightening torque | Notes | |

|---|---|---|---|---|---|

| AWG18 | Outer member | M4 | Extra-low profile hexagonal-socket-head type bolt1 | 1.5 N・m | Strength grade : 5.8 |

| Carriage | M5 | Bolt chosen by customer2 | 3.7 N・m | Recommended strength grade : 8.8 to 10.9 | |

| AWG28 | Outer member | M5 | Low-profile hexagonal-socket-head type bolt | 5 N・m | Recommended strength grade : 10.9 |

| Carriage | M5 | Bolt chosen by customer | 3.7 N・m | ||

| AWG35 | Outer member | M6 | Low-profile hexagonal-socket-head type bolt | 8.4 N・m | |

| Carriage | M6 | Bolt chosen by customer | 6.4 N・m | ||

| AWG43 | Outer member | M8 | Low-profile hexagonal-socket-head type bolt | 19.1 N・m | |

| Carriage | M8 | Bolt chosen by customer | 15 N・m | ||

- 1 For the Model AWG18, use the included extra-low profile bolts (M4×8L) for fixing the outer member in place.If using bolts other than these, make sure that they are M4 extra-low profile hexagonal-socket-head bolts. Using other bolts can result in the bolts and the wheels making contact, which may cause damage.

- 2 This is the tightening torque when the effective engagement length is 4.5 mm to 6.9 mm.

Lubrication

- Do not mix different lubricants. Even lubricants containing the same type of thickening agent may, if mixed, interact negatively due to disparate additives or oth er ingredients.

- The consistency of lubricant changes according to the temperature. Please keep in mind that the product’s sliding resistance may be affected by changes in viscosity. After lubrication, the sliding resistance of the product may increase due to the stirring resistance of the lubricant. Be sure to perform a warming-up operation and allow the lubricant to break in sufficiently before operating the machinery.

- Excess lubricant may spatter after lubrication. Wipe off spatter ed lubricant as necessary.

- Lubricant deteriorates over time, which decreases its lubricity, so perform regular inspections and replenish lubricant based on frequency of use.

- How often lubricant should be replenished varies depending on the operating conditions and environment. We recommend lubricating the system approximately every 100 km traveled (3 to 6 months).

The final lubrication interval/amount should be set at the actual machine.

Storage

When storing the slide rail, pack it as designated by THK and store it indoors in a horizontal position away from high or low temperatures and high humidity.

Please note that if the product has been kept in storage for an extended period, the lubricant inside may have deteriorated. Please ensure that you replenish the lubricant before use.

Disposal

The product should be treated as industrial waste and disposed of appropriately.