- Linear motion AI

Here, we introduce the benefits of implementing OMNIedge based on real-life examples of challenges such as failures in long robot transport axes and frequent guide replacement in a harsh operating environment.

Problems facing customers

1. Failure on the long robot transport axis causes extended downtime.

Multiple LM Guide units are connected to form a long transport axis of 15 m, 20 m, and so on. Although there are various factors such as damage occurring at joint transfer points and insufficient accuracy, planned replacements take about three days, and unexpected failure results in extended downtime (replacement includes teaching the robot).

2. LM guides are replaced frequently because the process is in a harsh operating environment.

A robot is mounted on the transport axis and is used in various processes. Because the surrounding environment during welding, picking, transportation, and special processing is extremely harsh, processing particles, liquids, and mist may get in and lead to LM guide damage. Despite having countermeasures against the environmental factors, is there a way to know the status of LM guides in advance?

OMNIedge is the solution!

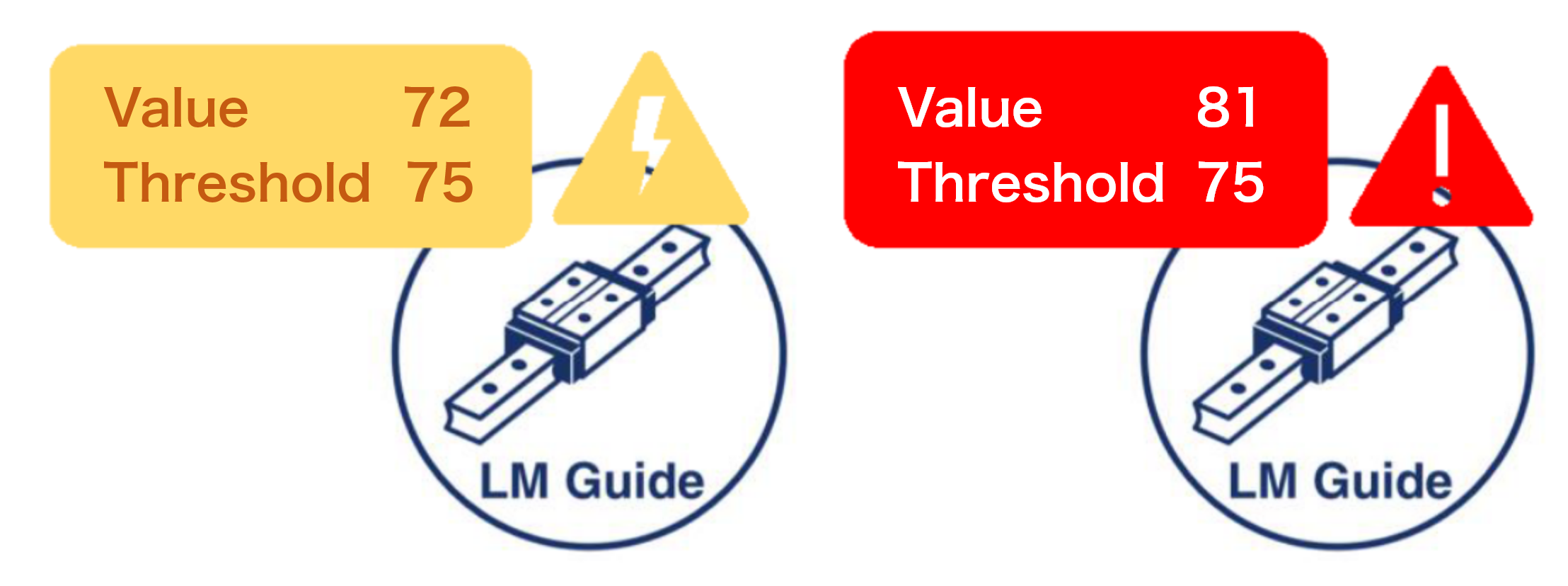

Visualize the status of components

Traditionally, judgement of the condition of components relied on human experience, intuition, and five senses. OMNI edge quantifies and visualizes the condition, enabling more accurate grasps of the situation.

Easily install on current equipment

The sensor is retrofittable on existing equipment. The communication network is automatically set up as soon as the sensor is installed and turned on.

Receive email notifications when a threshold is exceeded

You will be notified by email when the sensor detects abnormalities, allowing you to act before a catastrophic failure and extended downtime occur.

What kind of results can be expected?

OMNI edge can prevent sudden machine breakdowns and extended downtime!

Time Saving

➡Extended downtime repairs: 10 hours (operating day during the week)

➡Planned downtime repairs: 3 hours (non-operating day on a weekend)

Since the LM guide is located at the base of the device, it may take long time to replace. Being able to identify trends in advance can make a big difference.

OMNI edge minimizes unexpected downtimes and repairs, avoiding unexpected costs!

Cost Saving

➡Extended downtime costs: hundreds of thousands of dollars, exceeding $100,000 in certain cases

➡Planned downtime costs: 1/3 cost of extended downtime

Nobody wants those kinds of costs.

OMNI edge is easy to install, so you can easily attach the sensor during maintenance and continue to use it even after replacing the LM guide.