PPR-LR3 (full spec model)

| Features | PPR-LR3 (full spec model) |

|---|---|

| Z axis stroke | 30mm |

| Z axis resolution | 1μm |

| Θ axis stroke | 360° |

| Θ axis resolution | 0.01° |

| Load capacity | 80g |

| Thickness | 15mm |

| Force sensor resolution | 0.01N |

| Integrated pneumatic module | Yes |

Force Control Pick and Place Applications

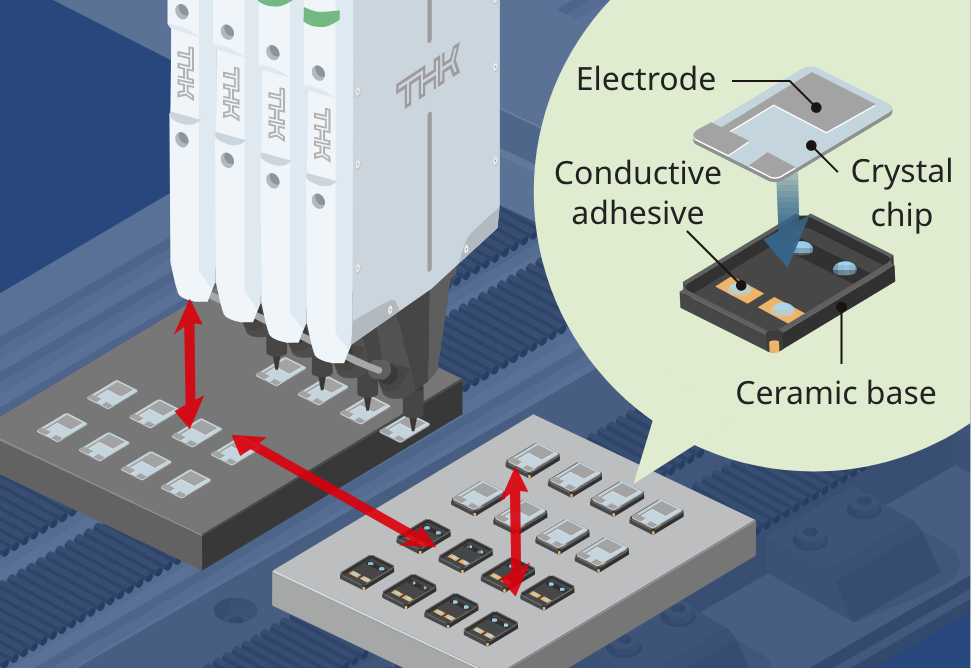

Assembly process

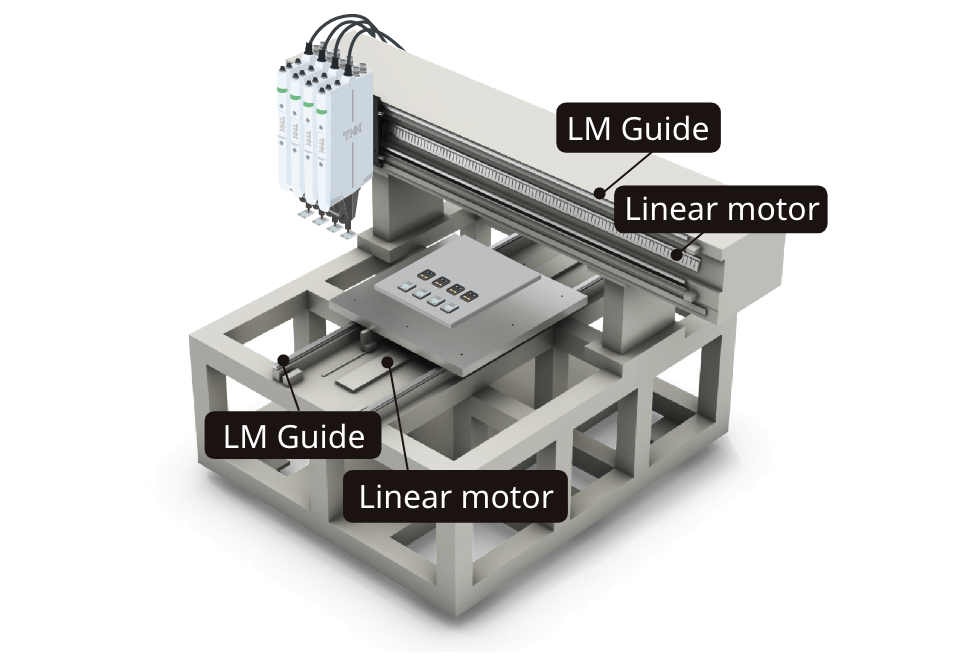

XY axis unit

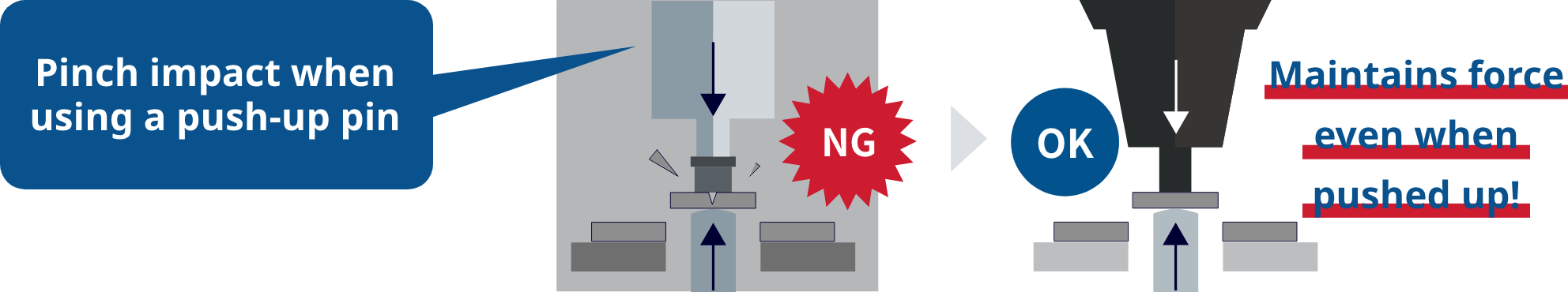

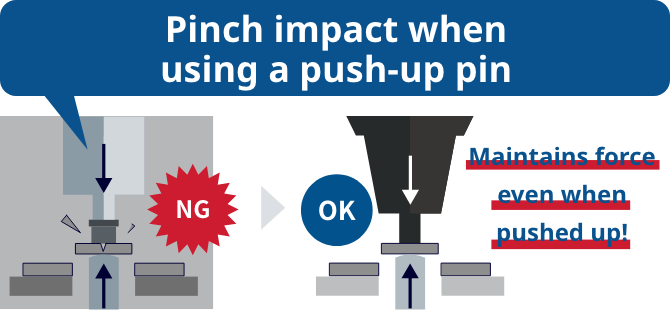

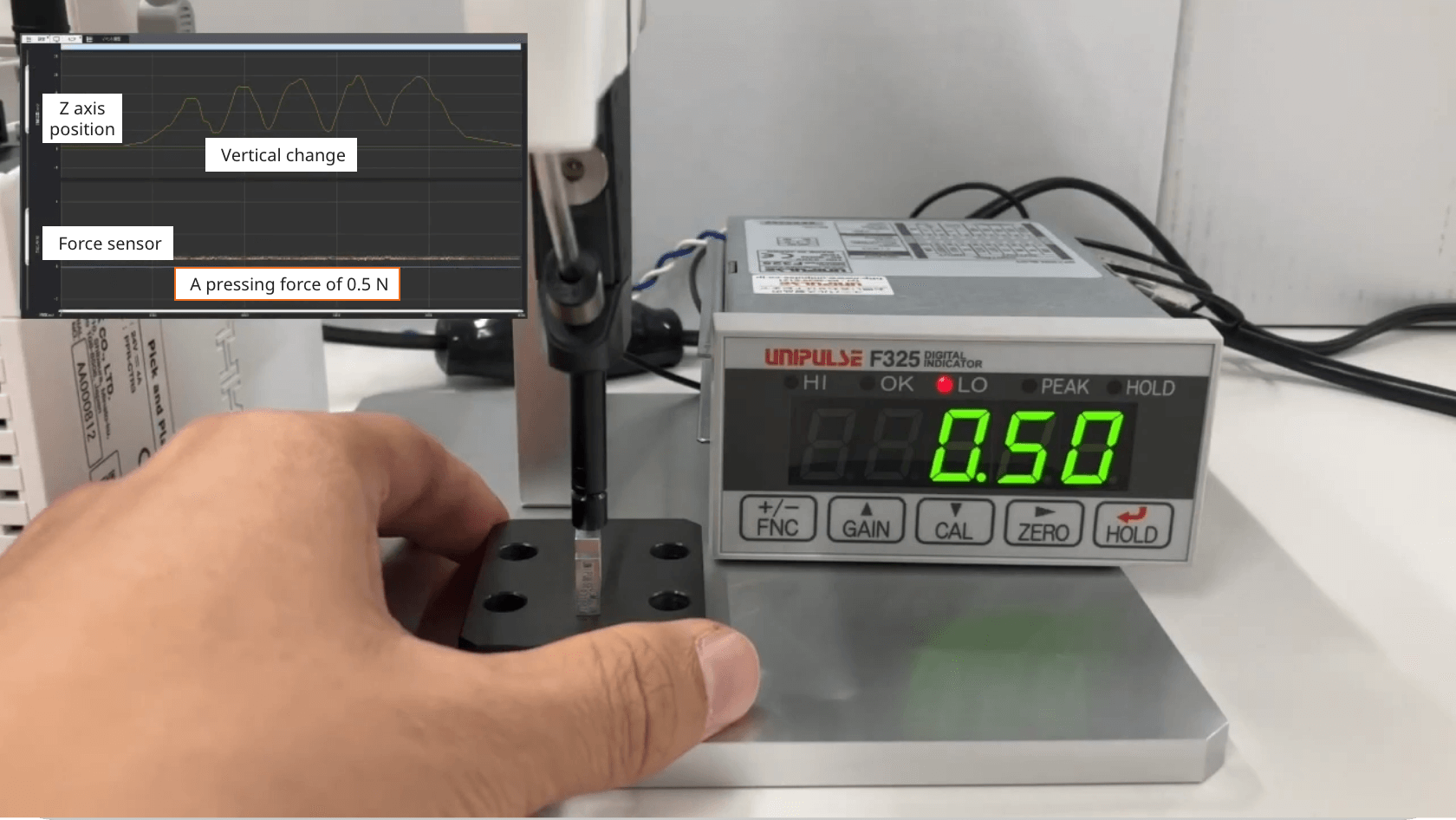

PPR: Video of push-up verification of force control

Please feel free to

contact us regarding

technical consultation

and price/delivery.

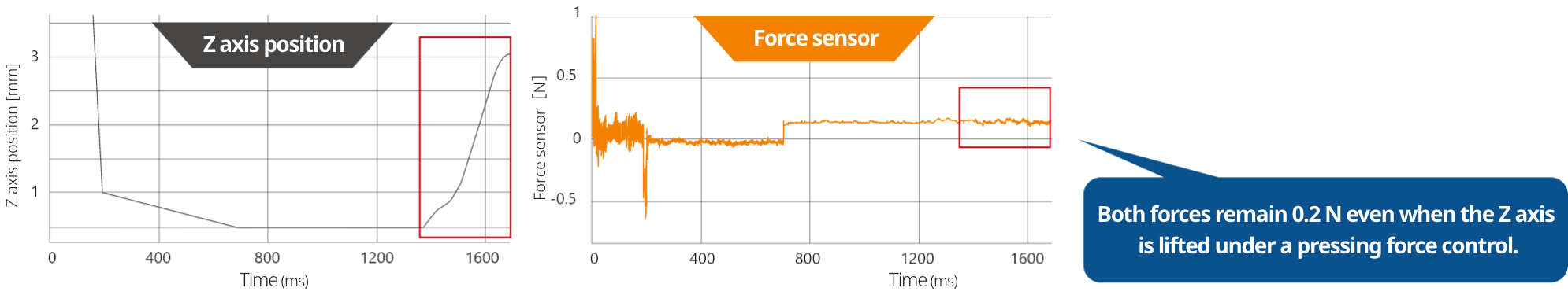

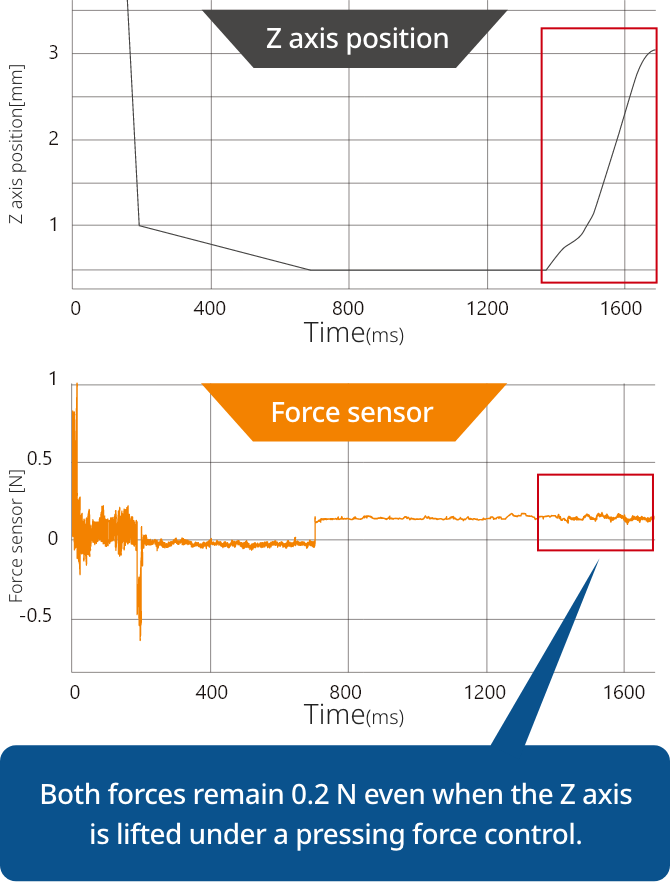

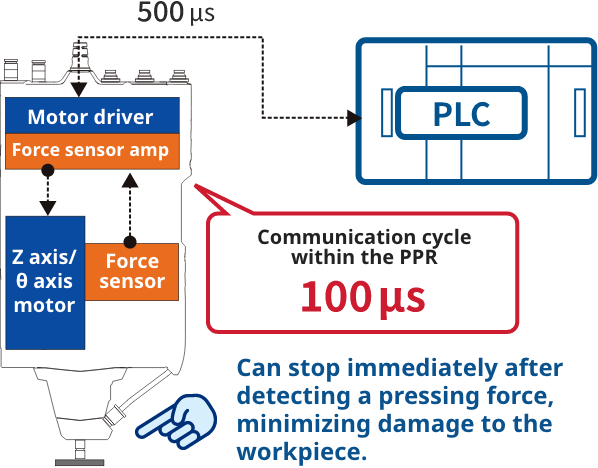

Factors Enabling High-Precision Force Control

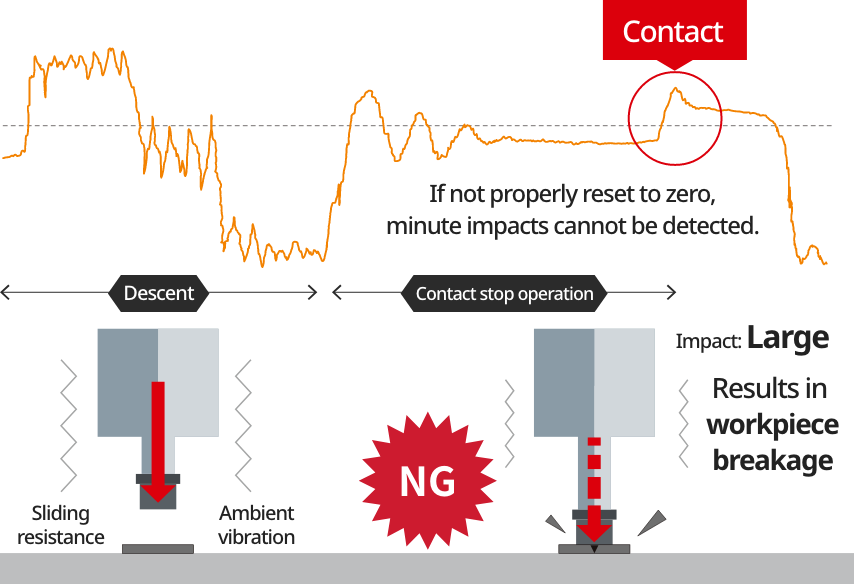

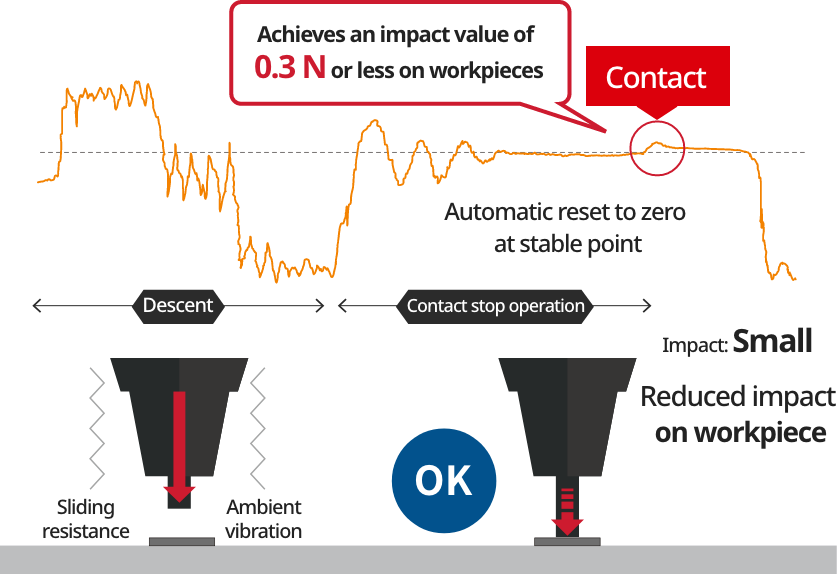

High-precision contact force detection

Unable to detect minute impacts upon workpiece contact due to sliding resistance and ambient vibration detection.

The unique algorithm automatically resets the reference value to zero based on the average value of sliding resistance and ambient vibration, and it detects the impact of workpiece contact.

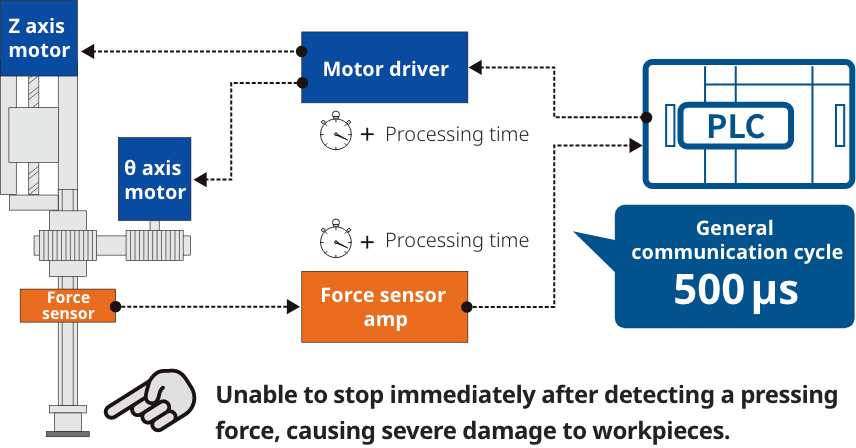

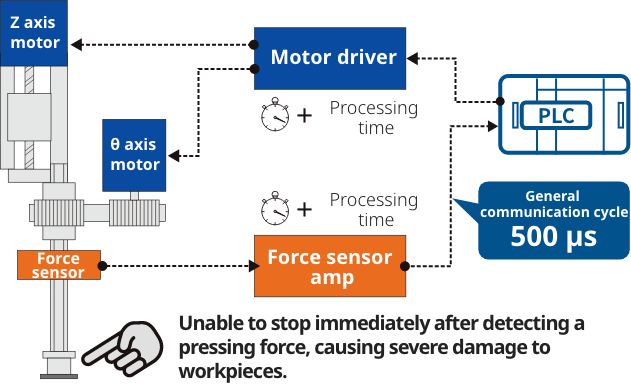

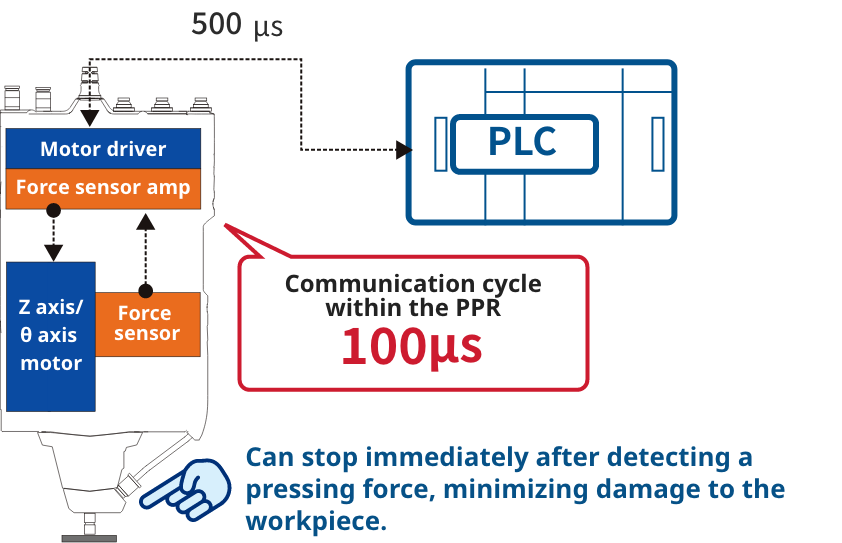

Immediate cessation upon contact

Examples of

proposed solutions

Problem

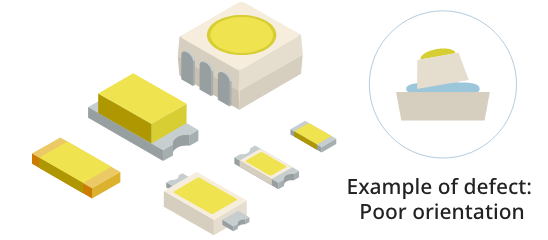

We are using adhesives when assembling elements and want to manage the force!

Selling point

It's great to have an all-in-one package with a force sensor integrated.

Since angle adjustment is also required, it is aligned from the position taken by the camera.

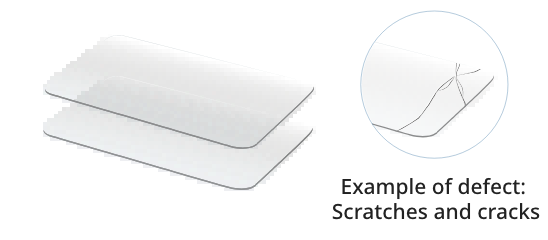

Problem

The cover of a module product has become thinner, and we want to manage damage by not pushing it down too much!

Selling point

The PPR is all-in-one, so it can be easily attached. Since there are numerous processes to pick and place small components, we want to adopt them as standard.

The force sensor confirms the impact force and can be used for traceability.

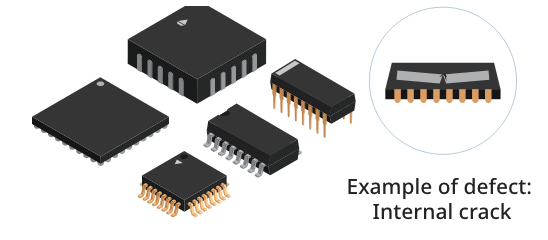

Problem

Workpieces develop cracks with more than a certain amount of load. We want to both reduce cycle time and manage damage!

Selling point

Using the contact stop function, the PPR was able to detect a load of 15 gf and stop. It was able to achieve under 0.2 seconds at a 5 mm stroke, satisfying our requirements.

Installation Support

Support staff who have mastered the use of the PPR will verify the implementation from many angles to ensure that there are no issues.

When considering a purchase of a product, we will interview you about your needs, starting from concepts such as "something like this" and "I want to run it like this." Please feel free to contact us.

Technical calculation

(cycle time/

transportability)

We can pre-calculate the feasibility of operation based on the mass and inertia of the conveyed object and its operation pattern.

Experiment

(workpiece pick and place trial)

We will experiment using actual workpieces, nozzles, etc. to determine whether or not the envisioned operation can be performed.

Demo machine rental

When considering a purchase, we will be happy to lend you a demo unit. Please contact us with the details you wish to confirm.

Sample program

We can provide a sample operation program that matches the actual usage concept. Please consult us about connecting to PLC.