Dec 10, 2025

Products

Green Transformation: Visualizing Factory Greenhouse Gas Emissions

Growing social awareness of the fight against global warming has presented the manufacturing world with the urgent challenges of decarbonizing supply chains and reducing factory greenhouse gas (GHG) emissions. Though visualizing energy consumption is a crucial first step toward reducing GHG emissions, most manufacturers only track consumption on the plant-wide level, so they can't see how much energy individual lines or machines are using. This makes it difficult to determine where to focus energy saving efforts and impossible to gauge their cost effectiveness.

That's where THK’s GX Solution, offered as part of our OMNIedge service, comes in. The GX Solution gets its name from the abbreviation used for green transformation, a sweeping effort to change society in ways that reduce greenhouse gas emissions while promoting economic growth. Quick and easy to install, it provides a more granular look at energy consumption from the plant-wide level down to individual lines and machines. In this article, we’ll talk about the OMNIedge GX Solution and how it can be used to tackle the energy challenges faced by production floors.

Manufacturing's Energy Management Challenges

Most production floors can track plant-wide electrical consumption but find it difficult to break down by line or machine. This makes it impossible to pinpoint where energy is being wasted and very difficult to prioritize efforts to reduce that waste. Many face the further challenge of not being able to collect data that shows the impact and cost effectiveness of energy-saving initiatives, which makes it difficult to evaluate any improvements that are made. All of this tends to slow projects down and delay investment decisions. Factory reorganization and the frequent changes that production lines undergo for variable-mix, variable-volume manufacturing only make matters worse, resulting in energy management woes specific to different departments and levels of management.

Plant Management and Production Engineering: Getting Energy Consumption Data Quickly

The difficulty of wiring an energy monitoring system out on the production floor hinders installation efforts, and manually aggregating energy consumption data is hardly efficient. Production floors also need to be able to see detailed energy use for individual production devices or for multiple machines grouped together. These challenges require an energy monitoring system that's easy to install.

Management (Owners of GHG Emissions Calculations): Balancing Costs and Operations

From management's perspective, production floors with frequent line updates and equipment changes are particularly challenging. While they might want to implement an energy monitoring system, conventional offerings are difficult to use because they are costly and require machines to be set up for communications. What they really need is something more flexible and less expensive.

Maintenance and Production: Avoiding Overage Fees

Monitoring energy consumption is a crucial task for any maintenance department. But if they're unable to balance demand monitoring with equipment maintenance needs, they run the risk of electricity overages. Especially for companies that operate close to the upper limit of their contracted energy consumption, there is a dire need for an efficient way to monitor that consumption.

These problems must be met and overcome as part of efforts to promote green transformation. Solving these problems is exactly what THK's OMNIedge GX Solution was designed to do.

What is the OMNIedge GX Solution?

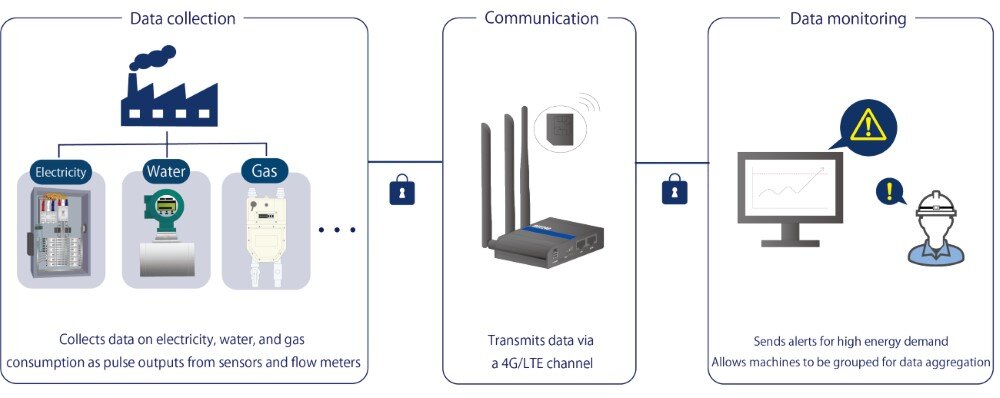

Despite being very quick to set up, the OMNIedge GX Solution supports visualization of factory-wide energy consumption (electrical, water, gas, etc.) at the level of individual processes and machines. It also contributes to strategic energy management by identifying where waste is preventing energy savings based on know-how obtained from THK’s ongoing efforts towards carbon neutrality at its own factories.

OMNIedge GX Solution features

- Easy set-up

Power sensors are daisy-chained together to minimize wiring and take up less space so they can fit inside narrow distribution boards. Dedicated communication channels make it possible to quickly aggregate energy consumption remotely.

- Visualizing energy consumption by line and machine

The sensor grouping feature makes it possible to calculate energy consumption rates by line and machine in addition to factory-wide energy consumption. This solution contributes to the generation of more effective energy-saving initiatives by accurately measuring the return on investment and environmental impact of equipment moves and the installation of more energy-efficient machines.

- See demand (maximum energy demand) in real time

Thresholds can be set in advance. If the demand is going to exceed a threshold, a message will be displayed on the application screen.

Benefits of Implementing the OMNIedge GX Solution

The OMNIedge GX Solution solves the problems faced by each of the departments and perspectives mentioned above.

Benefits for Plant Management and Production Engineering

- Hardware designed with the production floor in mind requires little wiring and vastly reduces installation work

- Energy consumption can easily be broken down by equipment category

- Simplified aggregation of energy consumption data

Benefits for Management (Owners of GHG Emissions Calculations)

- Dedicated communication channels eliminate the need to set up a network

- Updating and adding equipment is made easier, which allows the system to be used more flexibly

Benefits for Maintenance and Production

- Demand monitoring makes it possible to avoid excess energy consumption

- Real-time alerts facilitate rapid response

Efforts at the THK Yamaguchi Plant

Implementing the GX Solution has provided THK’s Yamaguchi plant (Sanyo Onoda, Yamaguchi Prefecture) with the following benefits.

Quick Aggregation of Energy Consumption

Using the GX Solution to provide constant, remote monitoring plant-wide and at the level of individual machines made data acquisition far more efficient than the on-site, manual data collection performed each month in the past.

Optimization of Operating Times

Analyzing acquired data to reevaluate when equipment is run has allowed the plant to reduce its standby power, which has helped lower its electricity costs overall.

Effective Capital Investment

Measuring and comparing the energy consumption and air flow of each of its air compressors helped the plant identify which of them were worn down. This made it clear which ones needed to be replaced soonest, which in turn allowed for the drafting of a more focused investment plan.

These benefits have directly contributed to energy and cost savings while also accelerating the plant’s efforts to become carbon neutral.

Post-Installation Support

With the GX Solution, we provide more than just a product. Using the knowledge we’ve gained in our efforts to become carbon neutral at the Yamaguchi plant, we also provide guidance and assistance both before and after implementation. Our support structure ensures that customers can actually use and see results from this tool once they’ve implemented it.

1. Initial meeting

After discussing the customer’s challenges and introducing the service, we help create structures conducive to system installation.

2. On-site inspection and official quote

THK sales and engineering staff check the site to determine how many devices are required for setup and how they should be configured.

(This takes about half a day and can be done while the facility is in operation.)

3. Construction

Customers arrange or perform their own electrical work.

THK will have a preparatory meeting with whoever is doing the electrical work to share a blueprint of what needs to be done.

(Construction takes between one and a few business days.)

4. User support

THK edits screen displays to reflect the names of the customer’s machines, and the sales team explains how to use the solution and provides follow-up after installation.

OEE Optimization System OMNIedge

THK first developed its OMNIedge IoT solution in 2020 to help reduce loss on the production floor. As an OEE optimization system, it has since come to provide a host of services aimed at reducing losses related to components, equipment, and even personnel.

- The Predictive Failure Detection AI Solution for linear and rotary motion components

- The Tool Monitoring AI Solution for machine tools

- The Integrated Maintenance Management System for optimizing maintenance work

- The Skill Management AI Solution for cloud-based employee skill management

The GX Solution, our sixth expansion of the OMNIedge system, was born of the need to address plant-wide energy management, a topic of increasing interest in discussions around OEE optimization.

Integration with Other OMNIedge Services and Future Developments

Even now, energy data captured by the OMNIedge GX Solution can be used in concert with the existing Failure Detection AI Solution to make it easier to see the relationship between equipment issues and energy loss. In the future, we plan to continue developing this new solution to help improve plant-wide productivity even further, with a function for detecting irregularities by comparing production results and energy data, high-level energy savings analysis driven by generative AI, expanded energy savings diagnostics, and more on the way. We’ll be looking at some of these in more detail in future articles.

The First Step to Energy Savings: Visibility

Accurately visualizing energy consumption is the first step toward reducing the manufacturing industry's GHG emissions. To that end, the OMNIedge GX Solution proves a ready ally to those in the manufacturing world who are moving to decarbonize their operations, providing a read-to-use, easy-to-install service that can quantify the effects of different initiatives. If you're interested in this powerful tool, don’t hesitate to contact THK.

THK Yamaguchi Plant Deploys the OMNIedge GX Solution, Accelerating Efforts to Reduce Energy Loss and Achieve Carbon Neutrality (News release)

Click here for the OEE Optimization System OMNIedge website

* This content is based on information that was released in Japanese on December 10, 2025.