Aug 20, 2025

Feb 18, 2026

Products

Customizing Ball Splines to Maximize Machine Performance

- Example of Use

- Column

- Product Introduction

- General Industrial Machinery

- Machine Tools

- Industrial Robots

- Precision Machinery / Instrument

- Electricity / Electronics

- Semiconductor Manufacturing Equipment

- Automotive and Transportation Equipment

- Picking Robot

- Articulated Robot

- THK Online Services

- High Rigidity

- Pick&Place

- Labor Savings

- Non-Magnetic

- High Accuracy

- High Speed

- Ball Spline

In our last article, we looked at the advantages of using ball spline rolling guides: sustained accuracy, enhanced durability, and reduced costs. This time, we’ll show how customizing ball splines for specific types of equipment can further enhance machine performance and share some customer use cases as well.

Customizations for When Standard Products Just Won’t Suffice

In the process of machine design, many engineers find that, try as they might, they simply cannot meet this or that requirement with existing standard products. In many cases, it is particularly difficult to use parts with standard specifications for mechanisms that require highly accurate positioning and machines intended to be used in special environments.

In these situations, we recommend customized ball splines. With multiple kinds of customization available, from modified dimensions and alternative materials to optimized surface treatment, we can create the perfect ball spline for your application. This solves the problems faced by machine designers and maximizes the performance of machines.

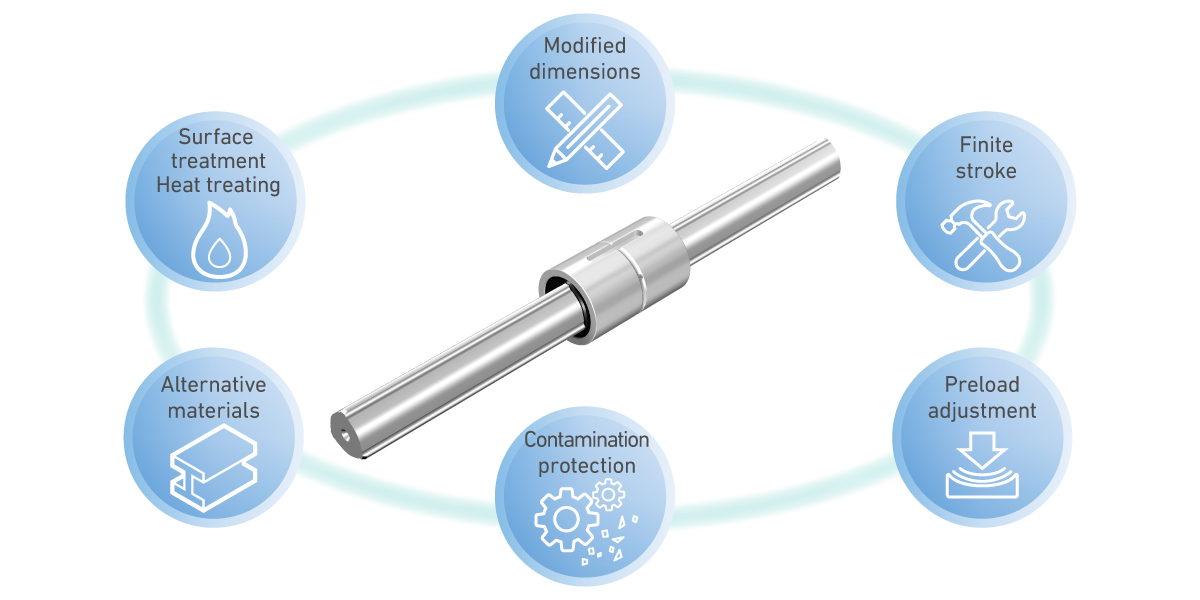

Ball Spline Customizations

In some situations, restrictive equipment parameters and operating environment make standard specifications less than ideal.

For these situations, ball splines can be customized in the following ways to meet the customer’s needs.

Modified Dimensions

If the length or outer diameter of standard products aren't appropriate for your equipment, we can make ball splines that match the dimensions you need.

Surface Treatment/Heat Treating

Surface treatment and heat treating can be performed to extend service life by increasing wear resistance and corrosion resistance. THK offers three kinds of surface treatment.

- AP-HC (industrial hard chrome plating)

Equivalent to industrial hard chrome plating, AP-HC provides almost the same level of corrosion resistance as martensitic stainless steel. In addition, it is highly resistant to wear since the film is extremely hard, at 750 HV or higher. - AP-C (industrial black chrome plating)

This treatment is a type of industrial black chrome plating designed to increase corrosion resistance. It costs less and achieves higher corrosion resistance than martensitic stainless steel. - AP-CF (industrial black chrome plating with special fluorocarbon resin coating)

This complex plating combines black chrome and a special fluorocarbon resin coating, making it suitable when high corrosion resistance is required.

Alternative Materials

It’s important to choose the right material for ball splines that will be used in high-temperature, non-magnetic, clean room, or other special environments.

- Stainless steel

Contributes to rust prevention in environments that require corrosion resistance

- Special alloy THK-NM1 (a non-magnetic material)

The following characteristics make this material suited to various special environments.

Non-magnetic properties: Relative magnetic permeability below 1.005 (equivalent to titanium)

High hardness: Heat treated for high hardness

High corrosion resistance: Preserves equipment performance even in environments with corrosive chemical spray

High-temperature tolerance: Retains its hardness in high-temperature environments (usable up to 300°C)

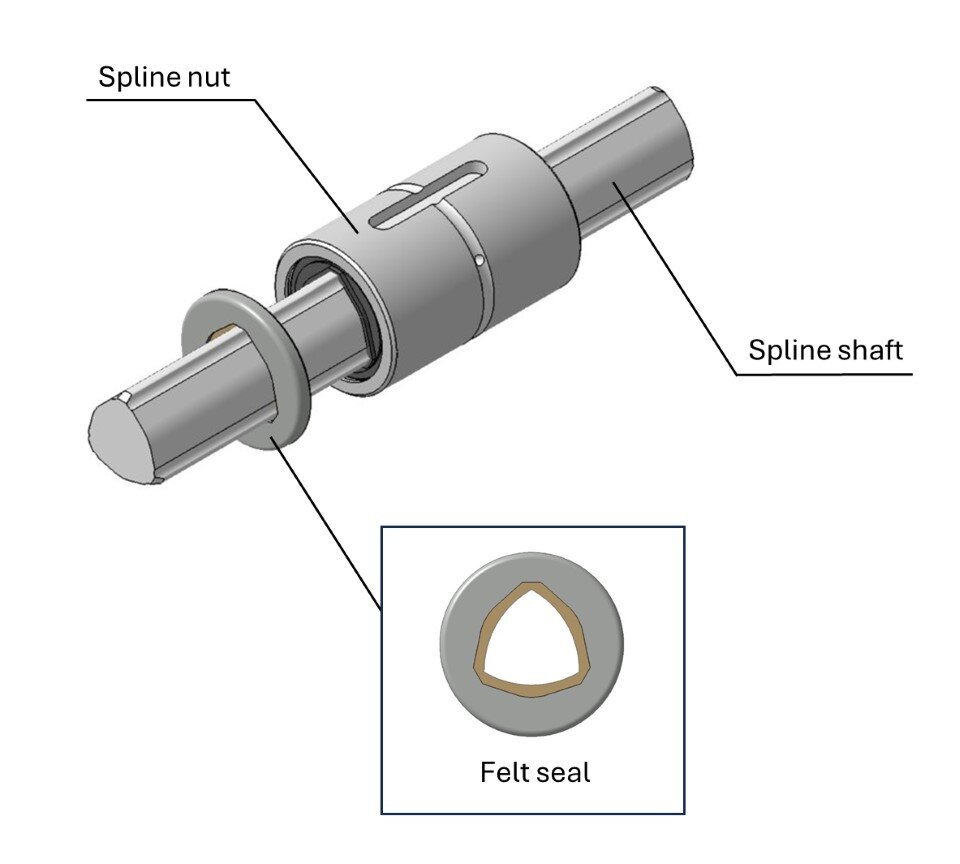

Contamination Protection

It is essential to keep debris and other foreign material from getting into the spline nut. Otherwise, they will cause abnormal wear and shorten the service life of the part. If it’s likely that debris or other foreign material would get into the spline nut, it is important to select a sealing device or contamination protection option suited to the intended operating conditions and environment.

One of the contamination protection options for ball splines is a highly wear-resistant special synthetic rubber seal. A felt seal that offers even stronger contamination protection is also available for some models.

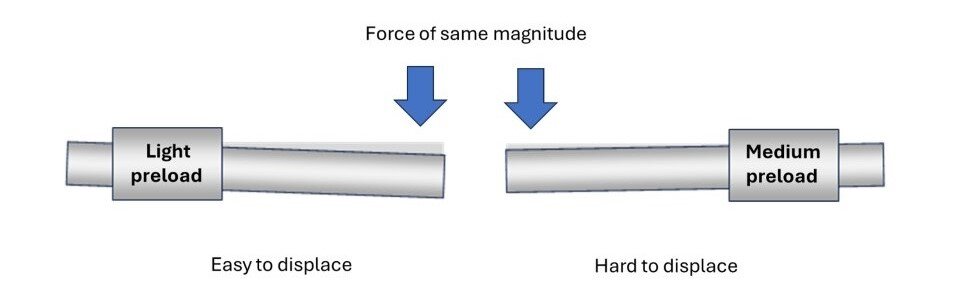

Preload and Rigidity Adjustment

Applying the right amount of preload for the desired application makes highly accurate positioning possible.

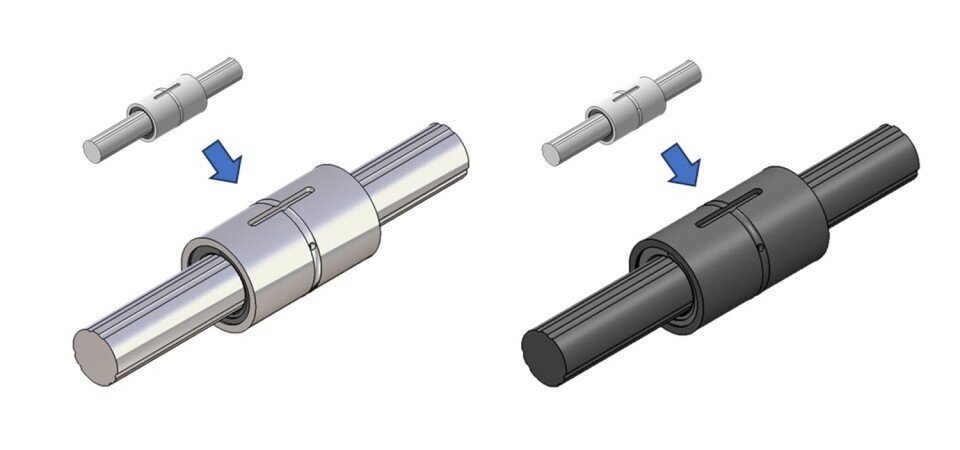

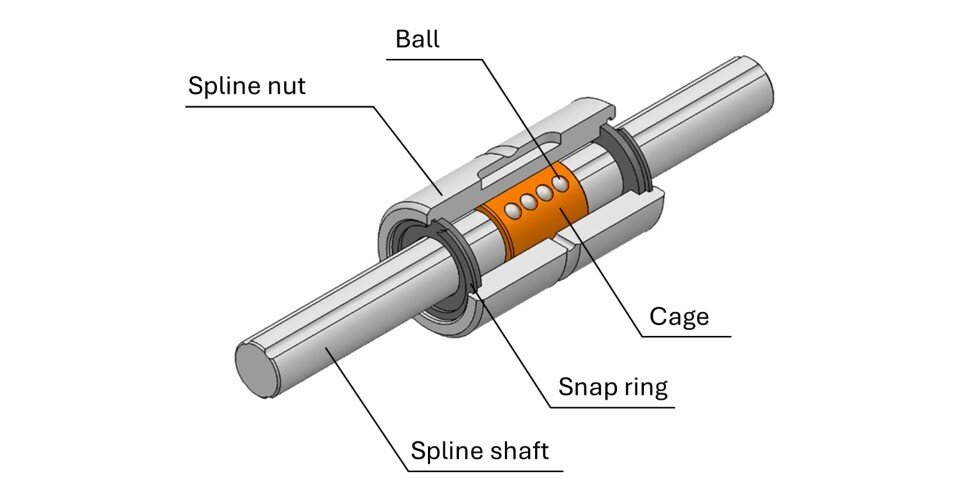

Finite Stroke

Removing a ball spline’s ball circulation mechanism makes it possible to reduce variances in rolling resistance.

This is ideal wherever smooth motion over a short stroke is required.

Customization for Optimal Ball Spline Design

These kinds of customizations transform a ball spline from being just another component into a crucial element enhancing a machine’s overall performance. Customization brings the following kinds of advantages.

Equipment optimization: Ball splines can be designed for optimal performance so that machines aren’t limited by existing standard products.

Long service life: Maintenance costs are reduced, even in harsh environments, by using ball splines designed to resist damage and wear.

Highly accurate operation: High-accuracy positioning is achieved by adjusting preload to enhance rigidity and reduce vibration and backlash.

Compatibility with special environments: Ball splines can be designed around the specific needs of food production, medical applications, semiconductor manufacturing, and more.

Custom ball spline designs provide the optimal solution to a customer’s specific needs, bringing higher accuracy, efficiency, rigidity, and reliability in addition to reduced costs.

We guarantee that our custom designs, tailored to your requirements, will maximize the performance and value of your equipment.

Case Studies: Designs for Special Environments/Special Applications

Let’s look at a few examples of places where customized ball splines are being used.

- Electron beam lithography and length measurement equipment: Alternative materials

These types of equipment are strongly affected by magnetism. Using ball splines made of non-magnetic materials with extremely low relative magnetic permeability allows these machines to operate consistently.

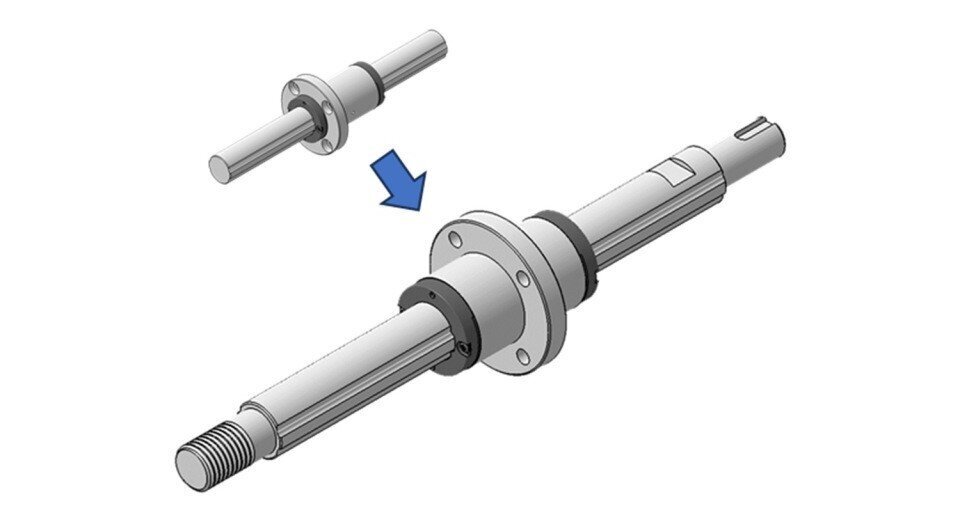

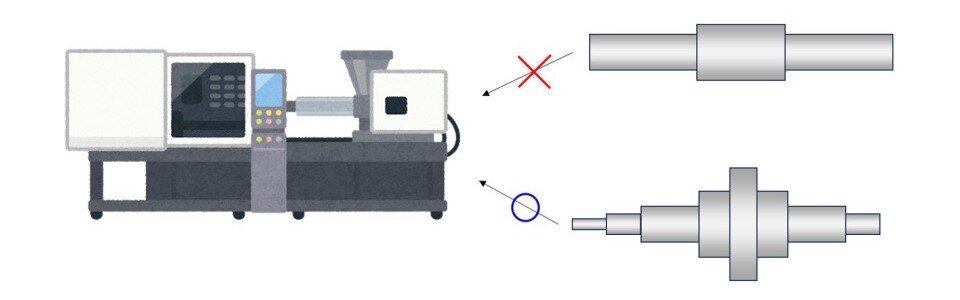

- Semiconductor manufacturing equipment: Modified dimensions and preload adjustment

These ball splines are customized to incorporate a housing assembly. We deliver them with a housing already installed rather than leaving the customer to attach one themselves, which is the more typical approach, and this allows us to guarantee the accuracy of the product in the form the customer will actually use rather than that of the ball spline alone. This customization improves positioning repeatability by 40% and contributes to greater equipment accuracy. Beyond contributing to improved accuracy, it helps reduce assembly costs on the customer’s end as well.

- Measurement devices: Finite stroke

These ball splines were customized to have a sliding part with a finite stroke rather than the typical infinite ball recirculation structure. They contain cages (retainers) that hold balls in ball pockets to prevent them from colliding and generating friction, which extends their service life and reduces dust generation. This makes equipment highly rigid and highly durable, makes the part itself more than eight times as durable (taking it from a conventional part’s slide count of 25 million to one around 200 million), and enhances the stability of the equipment’s measurement accuracy by leaps and bounds.

Design changes like these made to suit special environments and applications deliver performance that standard products just can’t provide.

Ball Splines Optimized to Your Equipment Specifications!

Ball spline customization can help enhance the performance and extend the life of your equipment. THK can propose ball spline specifications optimized to meet your requirements and will offer our full support to help resolve any challenges your designers may be grappling with.

For anyone who feels like, no matter how they try, they just can’t get standard products to do what they need, THK is here to help. Contact us today.

* This content is based on information that was released in Japanese on August 20, 2025.