Oct 29, 2025

Products

Achieving High-Speed Turning Performance with Turning Axis Bearings for Multitasking Multi-Axis Machine Tools

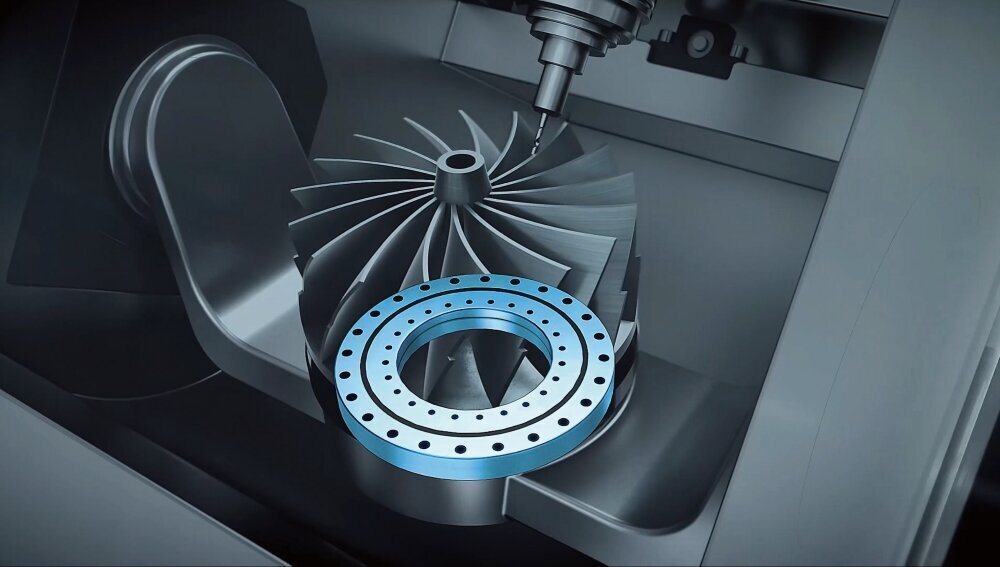

As the labor population shrinks due to an aging population and declining birthrate, manufacturing is facing an ever-intensifying labor shortage. Solving this challenge will require production-boosting technological innovation, one example of which that has been gaining traction is multitasking multi-axis machine tools. These devices make it possible to efficiently perform multiple processes in one mother machine, and companies use them to compensate for labor shortages and increase production efficiency. In this article, we’ll introduce you to the turning axis bearing, which needs to run at high speeds to facilitate the increasingly varied functions performed by machine tools.

The Need for High-Speed Rotation

The rising need for multitasking multi-axis machine tools has given birth to a market for products, including rotary tables, that are bestowed with advanced functionality. Recently, an increasing array of multitasking machinery has adopted tables that can rotate workpieces at high speed for lathe turning.

While workpieces used to be processed at a five-axis processing machine after being lathed, the use of multitasking machinery eliminates the need to unload and load workpieces between those processes, which also cuts out the additional step of adjusting for accuracy and helps boost overall accuracy and productivity. Facilitating the lathing process requires turning axis bearings to achieve a certain level of rotational speed, and further increasing the rotational speed of turning axis bearings will have a major impact on improving the quality of the machined surfaces of products and shrinking cycle times, so many companies are pouring effort into development activities.

The Trade-Off between High-Speed Performance and Heat Generation

There is, however, an unavoidable trade-off that turning axis bearings have to contend with: rotating at high speeds will generate heat. When the heat generated by turning axis bearings increases the temperature, that doesn’t merely have a negative impact on the lubrication or cause damage. It can also cause major problems by deforming the entire device and hurting the machining accuracy.

What Causes Heat Generation?

As we touched on in our "Rotary Bearings for Multi-Axis Multitasking Machine Tools” article, the turning bearings used in machine tool tables are supposed to have high rigidity and precision. Cross-roller rings are compact and highly rigid, and a single one is capable of bearing radial, axial, and moment loads, which makes them well-suited for this purpose. However, cross-roller rings are no exception when it comes to the trade-off that all turning axis bearings face.

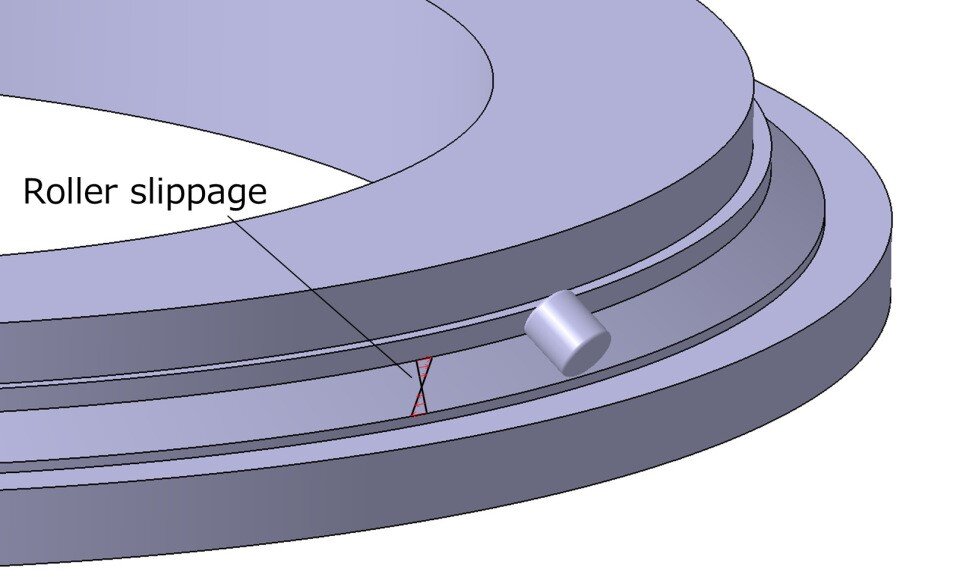

A cross-roller ring is a type of turning axis bearing that has a 45° contact angle, with a conical track formed between an inner and outer ring. It uses cylindrical rollers with a single cross-section as its rolling elements, so the circumference changes depending on their position within the conical track, and it’s that difference in circumference that creates slippage between the contact surface of the roller and the surface of the track. The amount of slippage is smallest at the center of the area where the roller makes contact, and it's largest around the ends of that contact surface. The direction in which the slippage occurs at both ends of the rollers is the opposite of their normal rotation, which causes a slip spin that further increases the friction.

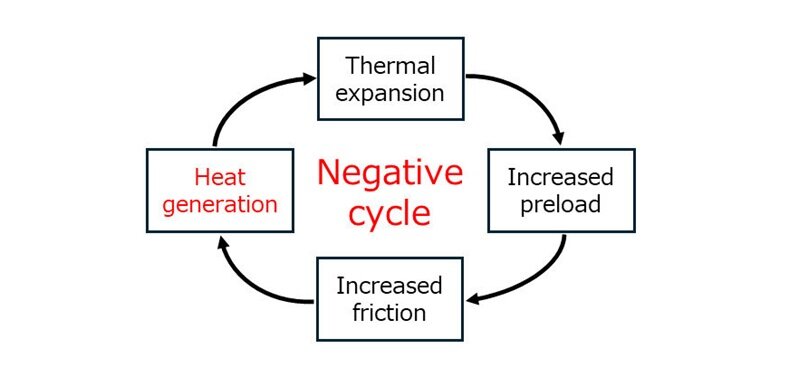

In addition to the temperature increase stemming from the heat generated during rotation, the cross-roller ring's contact structure also creates a negative cycle in which the inner and outer rings experience thermal expansion, causing the roller preload to increase, which in turn causes a spin slip that worsens friction and generates heat that then results in the inner and outer rings expanding further. When using cross-roller rings for high-speed rotation, precautions must be taken, such as supplying and circulating a large volume of lubricant within the bearing to utilize a forced lubrication technique that directly saps heat from the bearing.

A Roller Ring Specialized for High-Speed Turning Arrives on the Scene: The High-Speed Roller Ring Model RT

THK developed the High-Speed Roller Ring Model RT as a solution to the problem of increased temperatures caused by the heat generated during high-speed rotation.

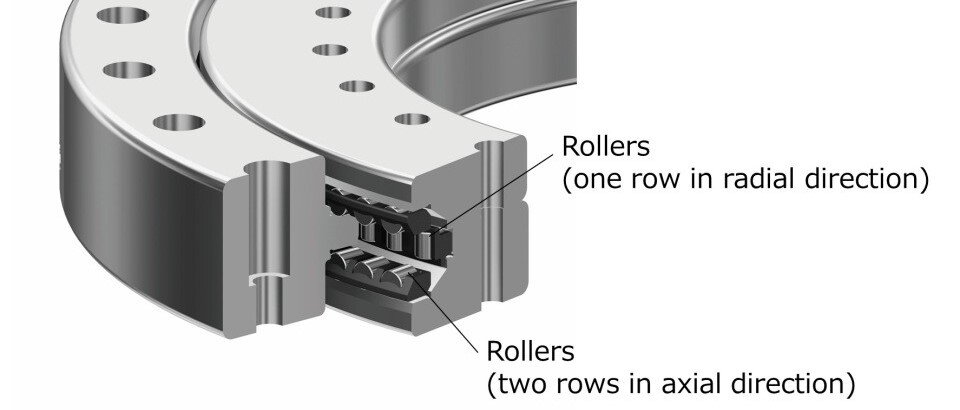

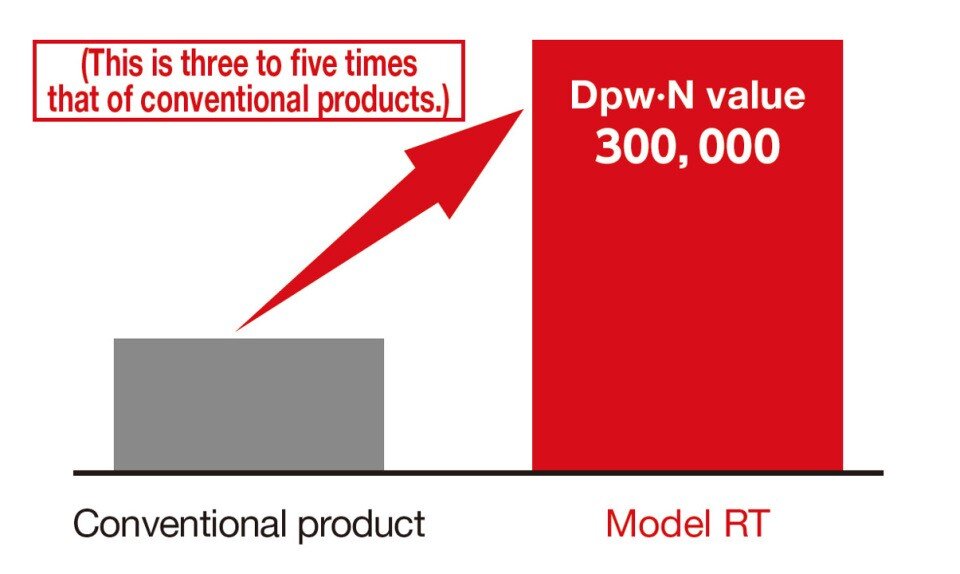

Similar to the cross-roller ring, the High-Speed Rotary Ring Model RT uses rollers for its rolling elements to achieve high rigidity. Its internal structure is designed for high-speed rotation, featuring two rows of rollers in the axial direction and one row in the radial direction. Each of the rollers has a 90° contact angle, which reduces the impact of a higher preload caused by thermal expansion. Additionally, the radial rollers have a differential slippage of 0, and even though the axial rollers do experience that kind of slippage, they are not significantly affected by increased preload arising from thermal expansion. As a result, the Model RT can rotate at speeds that surpass what the cross-roller ring is capable of, achieving a Dpw·N value of 300,000.

Different Types of Turning Axis Bearings for Different Applications

In addition to the High-Speed Rotary Ring Model RT, THK also offers another product that is designed for use in machine tool rotary tables: the Double-Row Angular Contact Roller Ring Model RW.

The Double-Row Angular Contact Roller Ring Model RW is a compact turning axis bearing that possesses over twice the rigidity of a similarly sized cross-roller ring. This highly precise product also guarantees a certain level of wobbling accuracy,* so it truly shines in applications that require high rigidity and high precision.

* Wobbling accuracy is a measure of the rotational accuracy of a bearing that excludes factors related to its shape (circularity, flatness, etc.) and represents only the rotational deviation of the bearing.

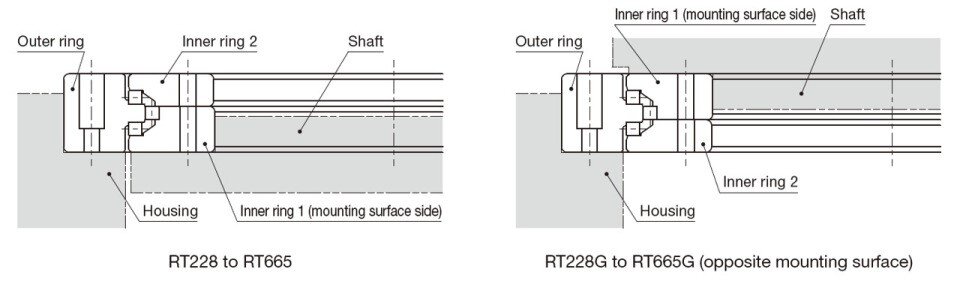

Both the Model RT and Model RW have mounting holes on their inner and outer rings, which reduces the number of components involved when assembling equipment (because there is no need for a presser flange to hold the bearing in place). Furthermore, both render preload adjustments unnecessary, because they already come with the appropriate preload. As the High-Speed Roller Ring Model RT is a roller ring optimized for high rigidity and high speed and it uses the same external dimensions as the Model RW, you can choose whichever suits the required specifications of a particular piece of equipment.

Boosting the Capabilities of Multitasking Machine Tools

In this article, we examined how the High-Speed Roller Ring Model RT offers advanced levels of high-speed performance and high rigidity. At THK, we will continue to develop products that respond to customers’ needs for machining accuracy, higher productivity, and compact designs that save on factory space.

Contact us if you’re struggling with designing multitasking multi-axis machine tools or with finding turning axis bearings that can operate at higher speeds.

* This content is based on information that was released in Japanese on October 29, 2025.