Sep 17, 2025

products

OMNIedge Adds Long-Awaited Compatibility with Spindles, Accelerating Maintenance Efficiency through an Expanded Lineup

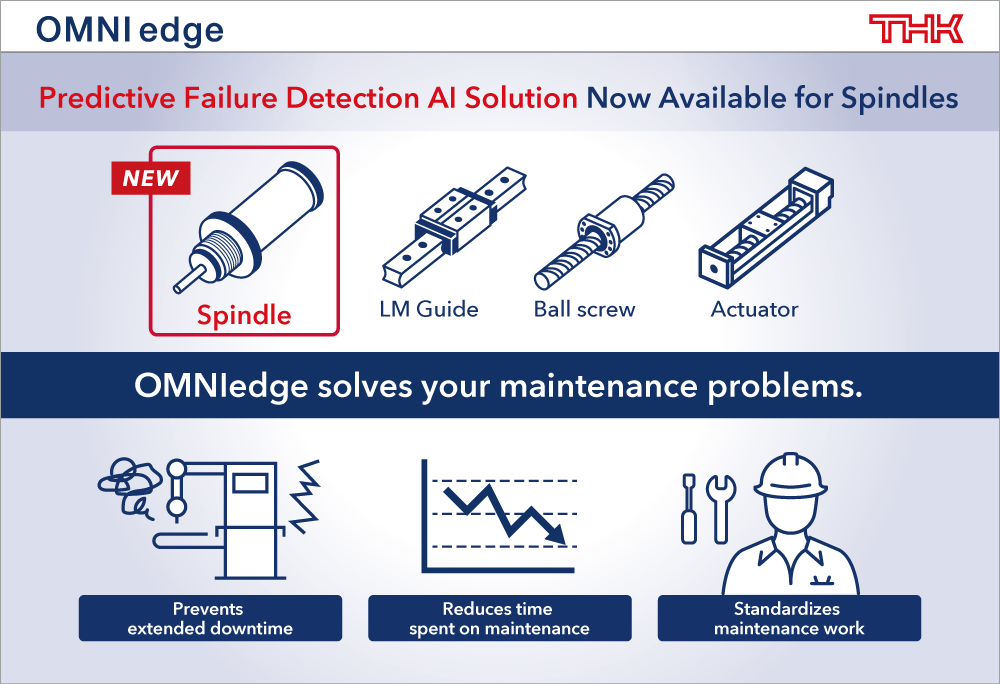

THK CO., LTD. (Location: Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) has expanded the types of components that can be analyzed with the Predictive Failure Detection AI Solution offered through the OEE Optimization System “OMNIedge.” In addition to the LM Guide units, ball screws, and actuators already covered, this service can now also be used for spindles, which are widely utilized in manufacturing facilities.

Helps Boost Maintenance Efficiency and Prevent Sudden Machine Failure

Through sensors retrofit onto the linear motion components (LM Guide units, ball screws, and actuators) installed on equipment, the Predictive Failure Detection AI Solution visualizes the status of components to capture abnormalities and notify staff so they no longer have to rely on their own senses to make a judgment call. This service has already been implemented in a variety of equipment, including machine tools, press machines, and transfer devices, where it has helped eliminate individual variability in maintenance work, avoid excessive maintenance, and prevent extended downtime caused by sudden equipment failure.

Lineup Further Expanded with Addition of Spindle Compatibility

The list of components that can be analyzed now includes spindles. These parts are widely used in machine tools such as machining centers and lathes, but they are larger and more expensive than other components, so many companies choose not to keep inventory on hand. This trend, in combination with the fact that the burden of production is often concentrated among a few machines, has led to issues with production lines experiencing extended downtime whenever a spindle suddenly fails. Expanding the lineup to enable diagnostics and damage visualization for spindles will minimize the risk of unanticipated downtime.

THK will continue to strengthen the features of existing OMNIedge solutions to provide the optimal version to users and help maximize their OEE.

Features

Spindle Status Can Be Visualized through a Retrofittable Sensor

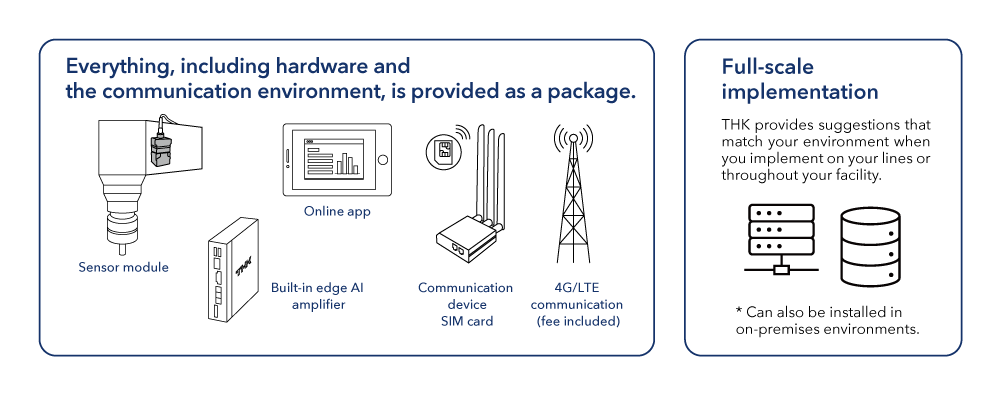

A sensor equipped with THK’s proprietary THK SENSING SYSTEM technology can be retrofit onto the body of a spindle within a machine that is already in use. This means the condition of the spindle can be quantified regardless of the machine's manufacturer or model year.

Fusion of Digital and Analog Elements

No thresholds need to be set, because the AI diagnostic service ADV automatically calculates the abnormality score with AI. In addition, THK's data scientists analyze the data and provide maintenance reports to grant extra peace of mind even after installation.

All-in-One Package

This all-in-one package includes hardware such as sensors and AI controllers, a communication environment, and software. Users don’t have to make any selections to get started.

※Abnormalities are detected by assessing the behavior of the spindle overall. They do not identify failures of specific components within the spindle. If an abnormality is detected, a thorough inspection of the spindle will be required.

Click here for the OMNIedge Predictive Failure Detection AI Solution catalogOEE Optimization System OMNIedge

OMNIedge is a system for reducing loss that occurs on the manufacturing floor and maximizing overall equipment effectiveness (OEE).

Note) This information was originally released in Japanese on September 17, 2025.

Contact information

|

|