Aug 27, 2025

products

OMNIedge Tool Monitoring AI Solution Now Connects with FANUC CNC in Real Time, Providing Potent Support for Factories with Mixed-Use Lines and Variable-Mix Production

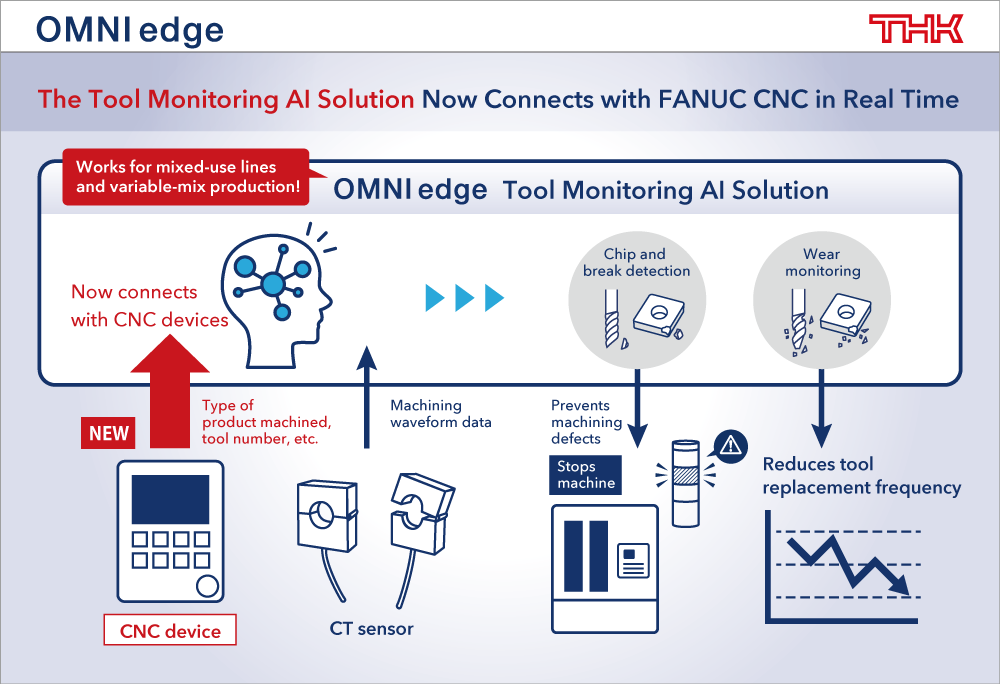

To strengthen the features of the Tool Monitoring AI Solution launched in November 2022 through the OEE Optimization System “OMNIedge,” THK CO., LTD. (Location: Minato, Tokyo; President: Takashi Teramachi; hereinafter referred to as “THK”) will begin offering connectivity with CNC (computer numerical control) devices from FANUC CORPORATION (Location: Minamitsuru, Yamanashi Prefecture; Representative Director, President and CEO: Kenji Yamaguchi; hereinafter referred to as “FANUC”) beginning September 2025. This connectivity will make it faster than ever to install and use the Tool Monitoring AI Solution, which will also prevent continuous defects and optimize cutting tool replacement timing by detecting tool damage and chipping.

Helps Prevent Machining Defects and Optimize Tool Life

The Tool Monitoring AI Solution obtains machining waveform data during everyday production through digital input signals from CNC devices, as well as current sensors attached onto the servo amplifier cables already on the machine tool, to develop a model of what regular production conditions look like so it can detect abnormalities in the tooling. Over the years, its ability to detect minute chips in tooling has helped prevent machining defects and optimize tool replacement timing when installed onto everything from conventional lathes and machining centers to automatic lathes and other machine tools under a variety of machining conditions (including tapping, drilling, and lathing with inner/outer diameter turning inserts).

Connectivity with CNC Devices Makes Setup and Operation Significantly Faster

This solution is now taking another step forward by adding connectivity with FANUC CNC devices. Until now, there have been cases where ladder programs would have to be edited or the type of product being machined would need to be manually designated for each set of waveform data to allow the input of digital signals from CNC devices, but with this new connectivity feature, machining programs and tool numbers can be pulled directly from CNC devices in real time to make operations and setup go smoother. Even in mixed-use or variable-mix, variable-volume operations where the type of product being machined changes, the system can automatically switch to the regular operation model associated with the current product in order to detect abnormalities more accurately.

THK will continue to strengthen the features of existing OMNIedge solutions to provide the optimal version to users and help maximize their OEE.

Features

Tool Abnormality Detection

Cycle data is extracted from input signals coming from the CNC device and current sensor installed on the motor to generate a model that can detect tool damage and chipping in real time to prevent the continuous generation of defects.

Tool Wear Monitoring

The cycle waveform from when the tool comes in contact with the workpiece is extracted to calculate the degree of wear. Analyzing the optimal tool life enables users to reduce the frequency of tool replacements and cut costs.

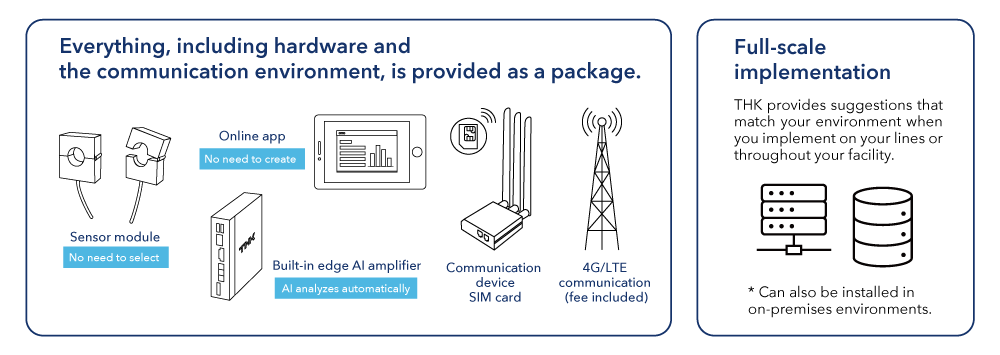

All-in-One Package

This all-in-one package includes hardware such as current sensors and AI controllers, a communication environment, and software. Users don’t have to make any selections to get started.

OEE Optimization System OMNIedge

OMNIedge is a system for reducing loss that occurs on the manufacturing floor and maximizing overall equipment effectiveness (OEE).

Note) This information was originally released in Japanese on August 27, 2025.

Contact information

Please direct any product inquiries to:

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Department, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail: thk-sp@thk.co.jp