High Torque Caged Ball Spline

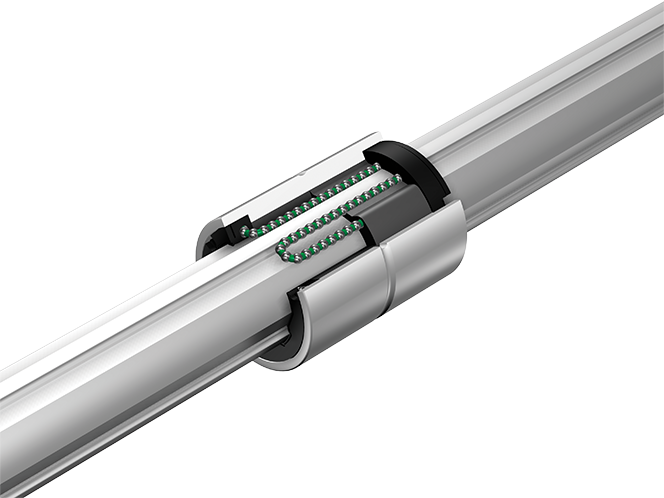

THK's cage technology, which is the culmination of its technologies and know-how, has been applied to ball splines.

The use of a ball cage maintains the aligned circulating motion and enables high-speed operation.

The cage prevents balls from impacting each other and causing mutual friction, enabling low noise and low dust generation. They also allow for long-term maintenance-free operation by improving grease retention.

The torsional rigidity of the nut is ensured through a high-torque structure. Shaft rigidity is also improved by approximating the form of the spline shaft to a circular shape.

Types

Highlight feature tags

- Long-term maintenance free

- High torque

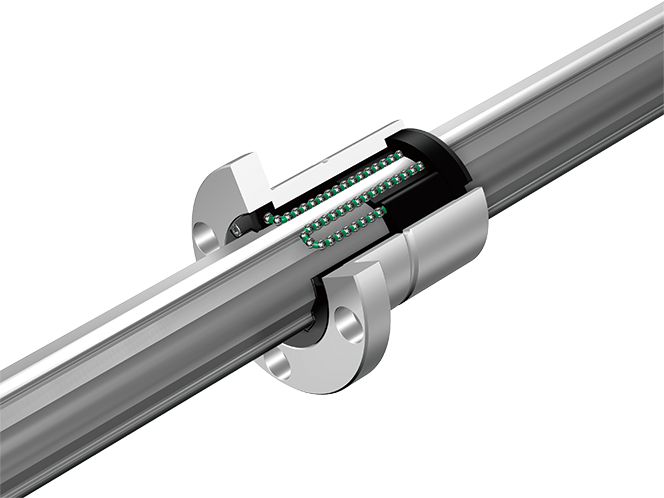

- Flanged type

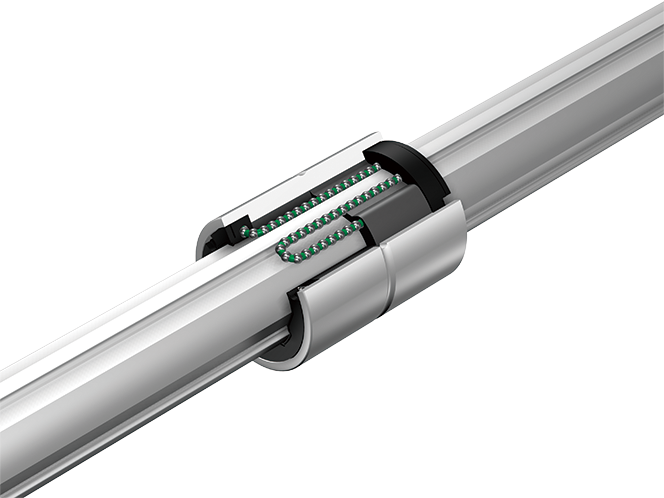

- Cylindrical type

- Solid spline shaft

- Hollow spline shaft

- Long-term maintenance free

- High torque

- Cylindrical type

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 25,30,40,50,60,70,80,100

- Long-term maintenance free

- High torque

- Flanged type

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 25,30,40,50,60,70,80,100

Features

Structure and features

The caged-ball technology, developed by bringing together THK’s technologies and know-how, is now integrated in the new Ball Spline.

The integration of the ball cage enables the circulating motion of evenly spaced balls and high-speed response to be achieved.

It eliminates collision and mutual friction between balls, and realizes low noise, pleasant running sound and low particle generation. As the grease retention is increased, long-term maintenance-free operation is also achieved.

The high-torque design provides the nut with excellent torsional rigidity. The spline shaft also has enhanced rigidity, thanks to its rounded design.

High-speed Response

Models SLS/SLF adopt the caged-ball technology to enable the circulating motion of evenly spaced balls to be maintained and high-speed response to be achieved, the cycle time of the machine can be improved.

|

Model tested |

SLS50 |

|---|---|

|

Testing environment |

22 to 27.5℃ |

|

Stroke |

1000mm |

|

Maximum speed |

200m/min |

|

Acceleration/deceleration |

5G(49m/s2) |

|

Applied load |

Light preload(CL) |

|

Lubricant |

THK AFB-LF Grease |

[Test results] No anomaly after travelling 10,000 km

Improvement on the spline shaft’s rigidity

Redesigning the shape of the conventional high torque type spline shaft to be more circular significantly improves its torsion and flexural rigidity.

|

Nominal shaft diameter 25 |

LBS |

SLS |

|---|---|---|

|

Minor diameter ø d |

19.5 |

21.6 |

|

Major diameter ø D0 |

24.5 |

25.0 |

|

Ball center-to-center diameter ø dp |

25 |

25.2 |

Low Noise, Pleasant Running Sound and Low Particle Generation

Models SLS/SLF adopt the caged-ball technology, they eliminate collision and mutual friction between balls, and realize low noise, pleasant running sound and low particle generation.

|

Model tested |

SLF50/LBF50 |

|---|---|

|

Stroke |

600mm |

|

Speeds |

30,50,100,150m/min |

|

Measuring instrument |

Noise level meter |

Overview of the test machine

|

Model tested |

SLF50CL+350LP/ LBS50CL+350LP |

|---|---|

|

Maximum speed |

30m/min |

|

Acceleration |

2.84m/s2 |

|

Stroke |

200mm |

|

Amount of air supplied |

1L/200s |

|

Lubricant |

THK AFE-CA Grease |

|

Equipment using the |

Particle counter |

Appearance of the test machine

Long-term Maintenance-free Operation

Models SLS/SLF adopt the caged-ball technology to substantially increase the grease retention, thus achieving long-term maintenance-free operation.

Smooth Motion (Small Rolling Fluctuation)

Models SLS/SLF adopt the caged-ball technology and a new circulation method, thus achieving stable and smooth motion with small rolling fluctuation.

|

Model tested |

SLF50 |

|---|---|

|

Speed |

10 mm/sec |

|

Applied load |

Medium preload(CM) |

|

Lubricant |

THK AFB-LF Grease |

Types of Spline Shafts

Precision Solid Spline Shaft (Standard Type)

Special Spline Shaft

Hollow Spline Shaft (Type K)

Housing Inner-diameter Tolerance

When fitting the spline nut to the housing, transition fit is normally recommended. If the accuracy of the Ball Spline does not need to be very high, clearance fitting is also acceptable.

|

Housing Inner-diameter Tolerance |

General conditions |

H7 |

|---|---|---|

|

When clearance needs to be small |

J6 |