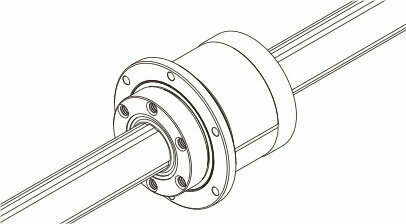

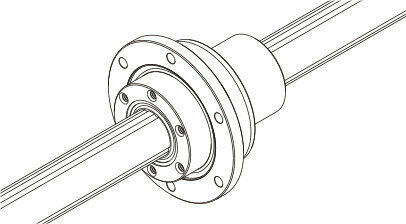

Rotary Ball Spline with Support Bearing

With the Model LTR rotary ball spline, the spline shaft has three crests on the circumference, and along both sides of each crest, two rows of balls (six rows in total) are arranged to hold the crest so that a reasonable preload is applied.

Angular-contact ball raceways are machined on the outer surface of the spline nut to constitute support bearings, allowing the whole body to be compactly and lightly designed.

The rows of balls are held in a special resin cage so that they stay aligned and recirculate. With this design, balls will not fall even if the spline shaft is removed.

In addition, a dedicated seal for preventing the inflow of foreign material into the support bearings is available.

Types

Highlight feature tags

- Lightweight

- Compact

- Rotary and linear motions

- Rotary

- With support bearing

- Solid spline shaft

- Hollow spline shaft

- Rotary and linear motions

- Rotary

- With support bearing

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 16,20,25,32,40,50,60

- Rotary and linear motions

- Rotary

- Compact

- With support bearing

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 8,10,16,20,25,32,40

- Lightweight

- Rotary and linear motions

- Rotary

- Compact

- With support bearing

- Solid spline shaft

- Hollow spline shaft

Spline shaft diameter (mm) : 16,20,25

Features

Structure and Features

With the Rotary Ball Spline model LTR, the spline shaft has three crests on the circumference, and along both sides of each crest, two rows of balls (six rows in total) are arranged to hold the crest so that a reasonable preload is applied.

Angular-contact ball raceways are machined on the outer surface of the spline nut to constitute support bearings, allowing the whole body to be compactly and lightly designed.

The rows of balls are held in a special resin retainer so that they smoothly roll and circulate. With this design, balls will not fall even if the spline shaft is removed.

In addition, a dedicated seal for preventing foreign material from entering the support bearings is available.

No Angular Backlash

Two rows of balls facing one another hold a crest, formed on the circumference of the spline nut, at a contact angle of 20° to provide a preload in an angular-contact structure. This eliminates an angular backlash in the rotational direction and increases the rigidity.

Compact Design

The spline nut is integrated with the support bearings, allowing highly accurate, compact design to be achieved.

Easy Installation

This ball spline can easily be installed by simply securing it to the housing using bolts.

High Rigidity

Since the contact angle is large and an appropriate preload is given, high rigidity against torque and moment is achieved. The support bearing has a contact angle of 30° to secure high rigidity against a moment load, thus to achieve a rigid shaft support. Model LTR-A, a compact type of LTR, has a contact angle of 45°.

Types and Features

Types of Spline Nuts

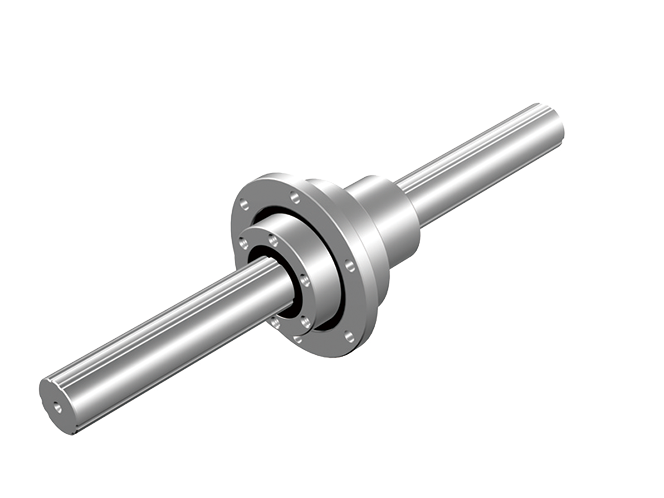

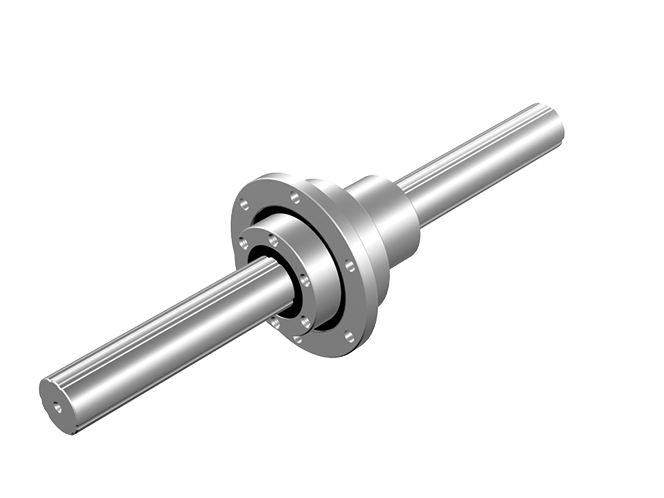

Ball Spline Model LTR

A compact unit type whose support bearings are directly integrated with the outer surface of the spline nut.

Specification Table⇒Details by model number: Model LTR

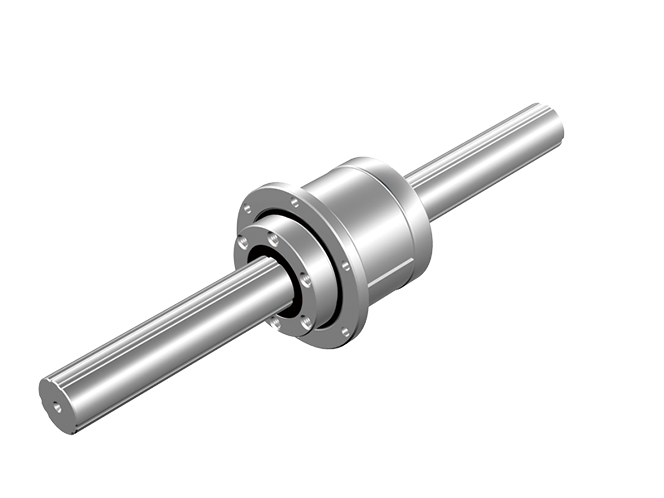

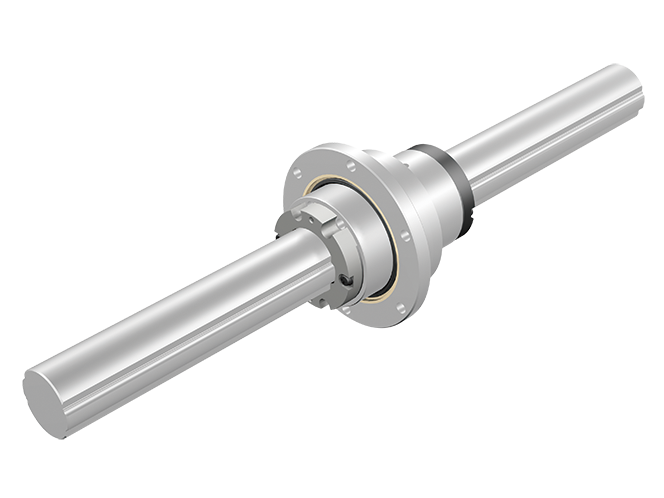

Ball Spline Model LTR-A

A compact type even smaller than LTR.

Specification Table⇒Details by model number: Model LTR-A

Types of Spline Shafts

For details,see Structure and Features.

Housing Inner-diameter Tolerance

For the housing inner-diameter tolerance for model LTR, class H7 is recommended.

Important note concerning model LTR

Note) Because of the divided outer ring, it is necessary to incorporate inner-diameter tolerance in the nut bracket (H7 is recommended) to prevent shifting of the outer ring on the side opposite the flange.