Selecting a Preload

A preload on the Ball Spline significantly affects its accuracy, load resistance and rigidity. Therefore, it is necessary to select the most appropriate clearance according to the intended use.

Specific clearance values are standardized for each model, allowing you to select a clearance that meets the conditions.

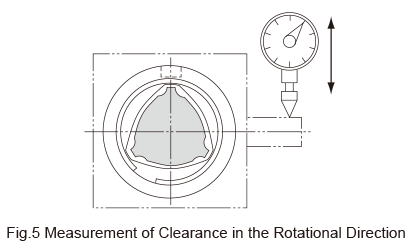

Clearance in the Rotation Direction

With the Ball Spline, the sum of clearances in the circumferential direction is standardized as the clearance in the rotational direction. For models LBS and LT, which are especially suitable for transmission of rotational torque, clearances in the rotational directions are defined.

Clearance in the rotational direction (BCD)

Preload and Rigidity

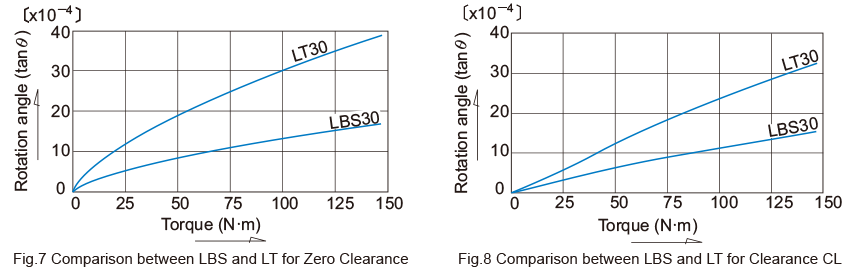

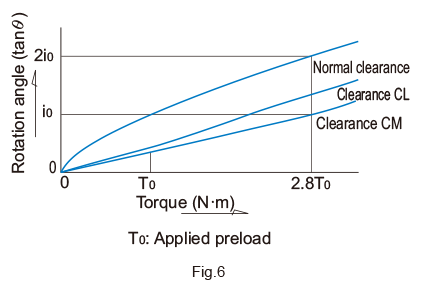

Preload is defined as the load preliminarily applied to the ball in order to eliminate angular backlash (clearance in the rotational direction) and increase rigidity. When given a preload, the Ball Spline is capable of increasing its rigidity by eliminating the angular backlash according to the magnitude of the preload. Fig.6 shows the displacement in the rotational direction when a rotational torque is applied.

Thus, the effect of a preload can be obtained up to 2.8 times that of the applied preload. When given the same rotational torque, the displacement when a preload is applied is 0.5 or less of that without a preload. The rigidity with a preload is at least twice greater than that without a preload.

Conditions and Guidelines for Selecting of a Preload

Table18 provides guidelines for selecting a clearance in the rotational direction with given conditions of the Ball Spline. The rotational clearance of the Ball Spline significantly affects the accuracy and rigidity of the spline nut. Therefore, it is essential to select a correct clearance according to the intended use. Generally, the Ball Spline is provided with a preload. When it is used in repeated circular motion or reciprocating straight motion, the Ball Spline is subject to a large vibration impact, and therefore, its service life and accuracy are significantly increased with a preload.

| Clearance in the Rotation Direction | Condition | Examples of applications |

|---|---|---|

| Normal grade (No symbol) |

|

|

| Light preload (CL) |

|

|

| Medium preload (CM) |

|

|