A Cross-Roller Ring in motion under an external load receives repeated stress on its raceways and rolling elements. When the stress reaches the limit, the surface of the raceways and rolling elements flake in places due to rolling fatigue. The service life of the Cross-Roller Ring is the total number of revolutions until the first flaking occurs on any of the raceways or the rolling elements as a result of rolling fatigue of the material. The nominal life defined below is used as an estimate for the service life of a Cross-Roller Ring. Nominal life is the total number of revolutions that 90% of a group of identical Cross-Roller Ring independently operating under the same conditions can achieve without flaking.

Calculating the Nominal Life

The nominal life (L10) is obtained from the following formula using the basic dynamic load rating (C)and the load applied to the cross-roller ring (PC).

Calculating the Modified Nominal Life

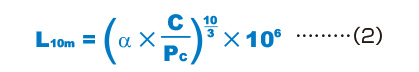

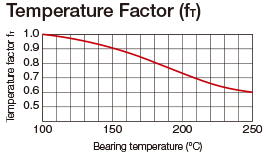

During use, a cross-roller ring may be subjected to vibrations and shocks as well as fluctuating loads, which are difficult to detect. In addition, the operating temperature will have a decisive impact on the service life. Taking these factors into account, the modified nominal life (L10m) can be calculated according to the following formula (2).

Modified factor α

Modified nominal life L10m

- Note) The normal service temperature is 80℃ or below. If the product is to be used at a higher temperature, contact THK.

- * The basic dynamic load rating (C) of the cross roller ring shows the radial load under which the nominal life is 1 million revolutions when a group of identical cross roller ring units independently operate, assuming a constant direction and magnitude of the load. Basic dynamic load ratings (C) are indicated in the specification tables.

- * Rated life is calculated according to load and presumes optimal mounting conditions and adequate lubrication.Usage involving back-and-forth motion or low-speed operation may affect lubrication requirements. Please consult THK for assistance in calculating service life for usage involving back-and-forth motion or low-speed operation.

fw :Load Factor

Machines that perform rotary movements are often subjected to vibration and impact during operation. It is difficult to accurately identify the cause of vibration from a motor, gears, or other drive components, or of impact arising from frequent starts and stops.

In the event of excessive vibration or impact, divide the basic dynamic load rating (C) by thecorresponding load factor, using the empirically obtained figures in Table1 as guidelines.

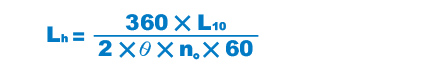

Calculating the Service Life Time

For Rotary Motion

- * If rotated continuously, significant heat may be generated depending on the rotation speed. Consult with THK about the rotation speed.

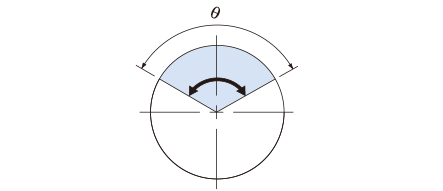

For Oscillatory Motion

- * Rocking angle: If θ is too small, this will hinder the formation of an oil film on the contact surfaces between the race and the roller and may cause fretting. If the product will be used in these conditions, contact THK.

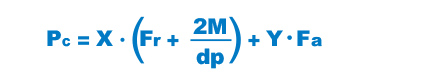

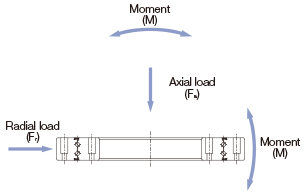

Dynamic Equivalent Radial Load PC

The dynamic equivalent radial load of the Cross-Roller Ring is obtained from the following equation.

Table2 Dynamic Radial Factor and Dynamic Axial Factor

| Classification |

X |

Y |

|

|

1 |

0.45 |

|

|

0.67 |

0.67 |

- ● If Fr = 0N and M = 0 N・mm, perform calculation while assuming that X = 0.67 and Y = 0.67.

- ● For service life calculation with a preload taken into account, contact THK.