Full-Ball LM Guide Wide-Rail Model HRW

This LM Guide model possesses a low center of gravity thanks to its large rail width and low overall height. As a result, it can be used as a single rail in places where a compact design or high rigidity against an applied moment is required.

Size : 12,14,17,21,27,35,50,60

Types

Highlight feature tags

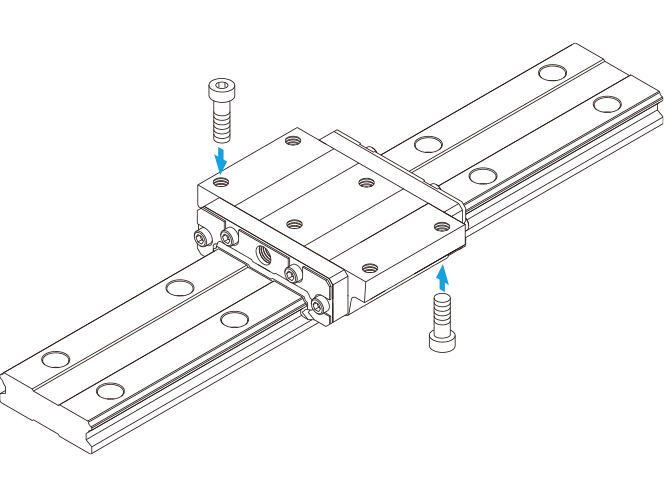

- Flange

- Bolts mounted from above and below

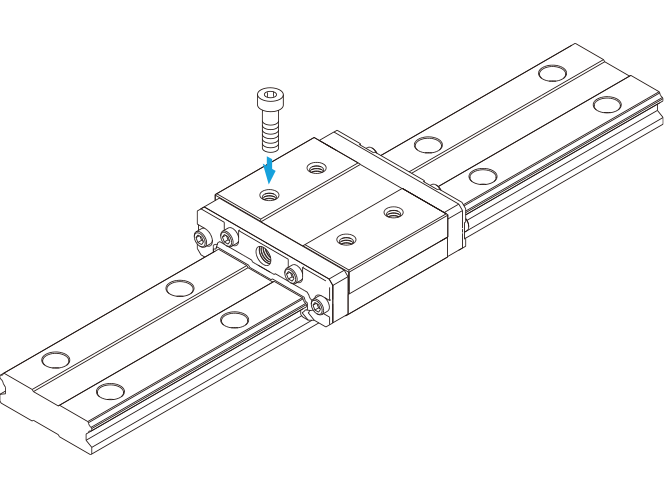

- Bolts mounted from above

- Flange

- Bolts mounted from above and below

Basic load rating (kN): Basic dynamic load rating 5.53 to 80.3 / Basic static load rating 9.1 to 109

Size :

17,21,27,35,50,60

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 5.53 to 62.4 / Basic static load rating 9.1 to 86.3

Size :

17,21,27,35,50

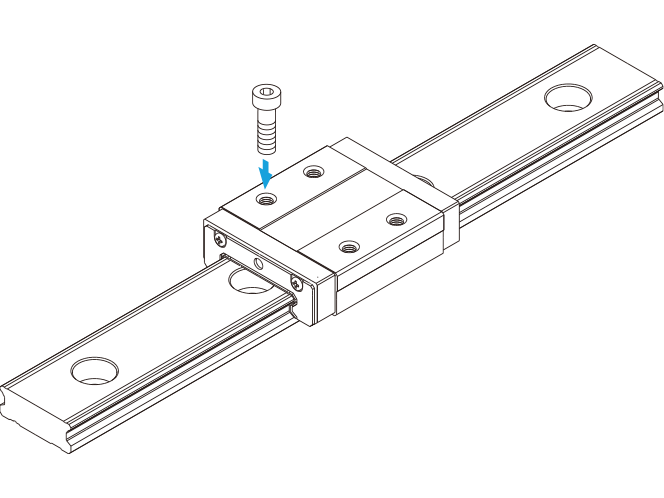

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 3.29 to 5.38 / Basic static load rating 7.16 to 11.4

Size :

12,14

Features

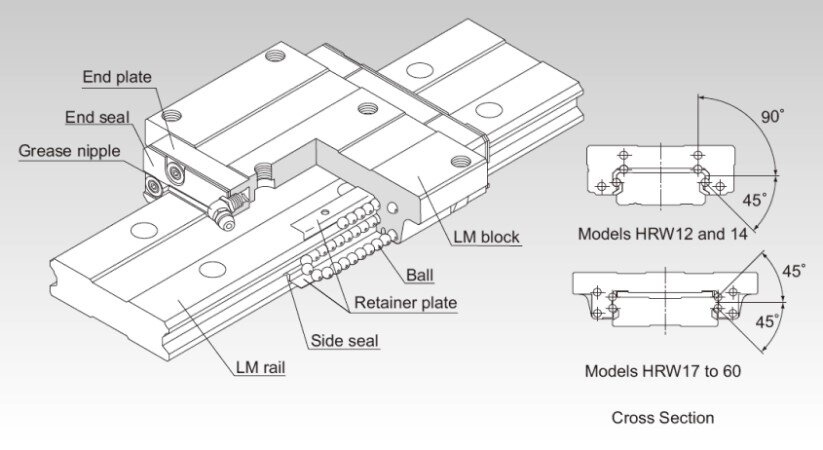

Structure and Features

Balls roll in four rows of raceways precision-ground on an LM rail and an LM block, and endplates incorporated in the LM block allow the balls to circulate. Since retainer plates hold the balls, they do not fall off even if the LM rail is pulled out. (except models HRW 12 and 14LR). Each row of balls is placed at a contact angle of 45 so that the load ratings applied to the LM block are uniform in the four directions (radial, reverse-radial, and lateral directions), enabling the LM Guide to be used in all orientations. In addition, the LM block can receive a well-balanced preload, increasing the rigidity in the four directions while maintaining a constantly low friction coeffi cient. The LM rail is wide and has a low center of gravity with a low overall height, so it can be used as a single axis in locations where space is limited or where high rigidity is required due to moment loads.

Compact with Large Load Capacity

Because of the large number of load-bearing balls, this model is highly rigid in all directions. The LM rail is wide and suffi cient to receive a moment load even in a single rail configuration. Additionally, since the secondary cross-sectional moment of inertia of the LM rail is large, the rigidity in the lateral directions is also high. Accordingly, it does not need reinforcement such as a side support.

Self-adjustment Capability

The self-adjustment capability through front-to-front configuration of THK’s unique circular-arc grooves (DF set) enables a mounting error to be absorbed even under a preload, thus to achieve highly accurate, smooth straight motion.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Lengths and Maximum Lengths of LM Rails

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |