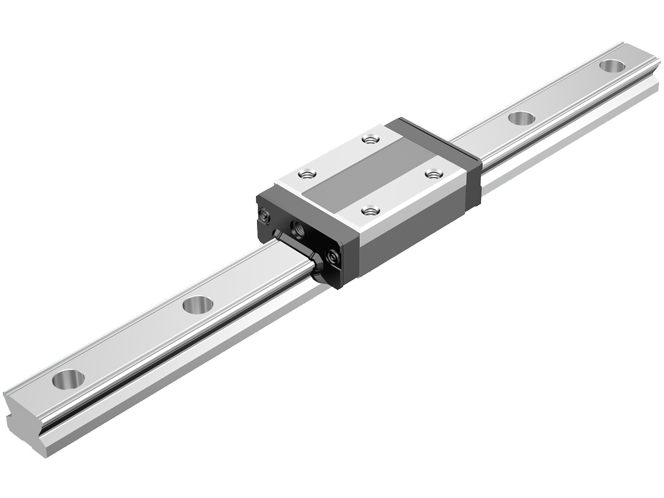

Full-Ball Type LM Guide Radial Type Model SR

Since it is a compactly designed model that has a low sectional height and a ball contact structure capable of receiving a large load in the radial direction, this LM Guide is optimal for horizontal guide units.

Size : 15,20,25,30,35,45,55,70,85,100,120,150

Types

Highlight feature tags

- Flange

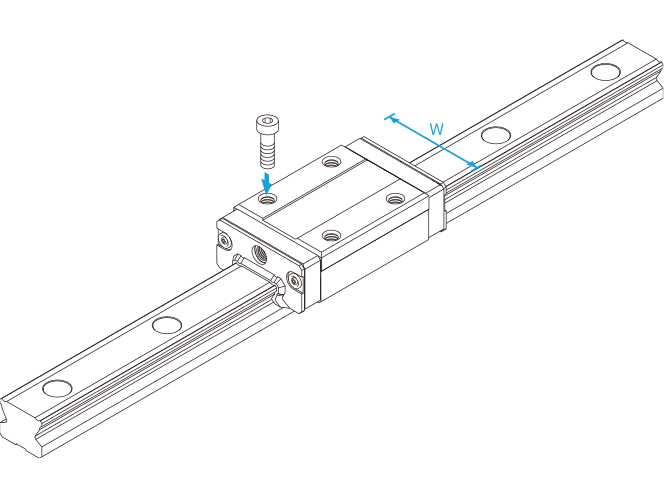

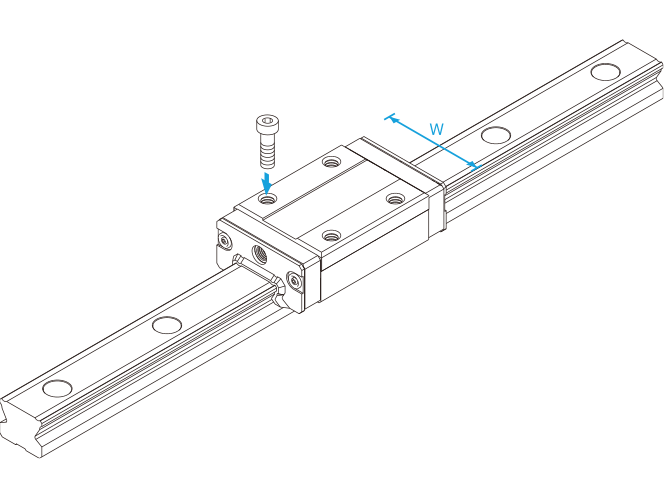

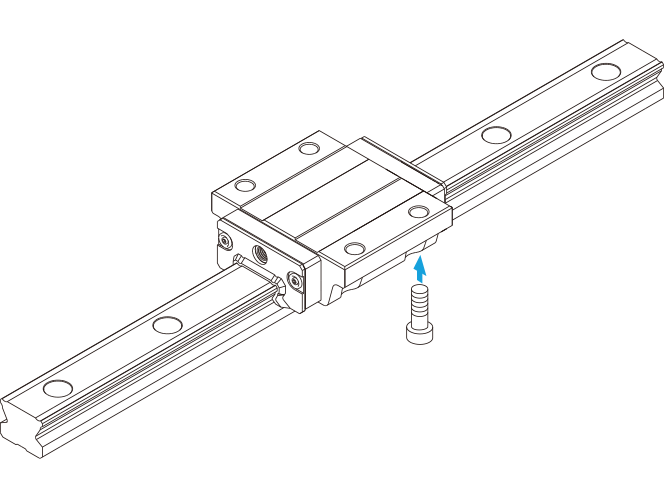

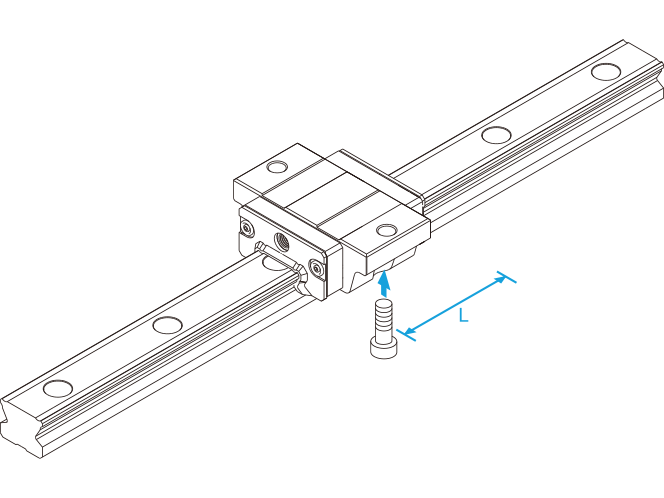

- Bolts mounted from above

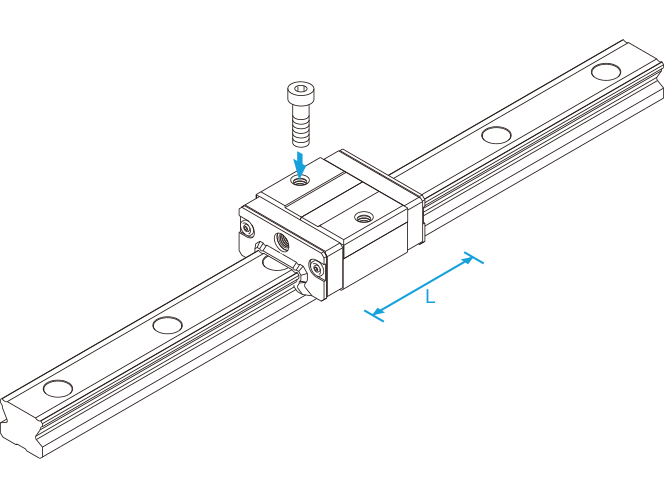

- Bolts mounted from below

- Short block (LM Guide)

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 13.8 to 136 / Basic static load rating 20.5 to 179

Size :

15,20,25,30,35,45,55

- Short block (LM Guide)

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 9.1 to 40.9 / Basic static load rating 11.7 to 46.7

Size :

15,20,25,30,35

- Bolts mounted from above

Basic load rating (kN): Basic dynamic load rating 226 to 411 / Basic static load rating 282 to 537

Size :

70,85,100,120,150

- Flange

- Bolts mounted from below

Basic load rating (kN): Basic dynamic load rating 13.8 to 136 / Basic static load rating 20.5 to 179

Size :

15,20,25,30,35,45,55

- Flange

- Short block (LM Guide)

- Bolts mounted from below

Basic load rating (kN): Basic dynamic load rating 9.1 to 40.9 / Basic static load rating 11.7 to 46.7

Size :

15,20,25,30,35

Features

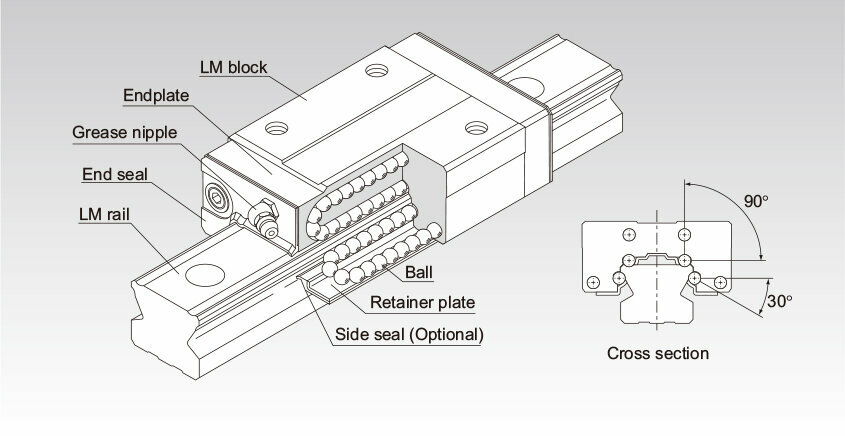

Structure and Features

Balls roll in four rows of raceways precision-ground on an LM rail and an LM block, and endplates incorporated in the LM block allow the balls to circulate. Since a retainer plate holds the balls, they will not fall off even if the LM block is removed from the LM rail. With the low sectional height and the high rigidity design of the LM block, this model achieves highly accurate and stable straight motion.

Compact, Heavy Load

Since it is a compact designed model that has a low sectional height and a ball contact structure rigid in the radial direction, this model is optimal for horizontal guide units.

Mounting accuracy can easily be achieved

Since this model is a self-adjusting type capable of easily absorbing an accuracy error in parallelism and level between two rails, highly accurate and smooth motion can be achieved.

Low Noise

The endplate installed at each end of the LM block is designed to ensure the smooth and low-noise circulation of the balls at the turning areas.

High Durability

Even under a preload or excessive biased load, differential slip of balls is minimal. As a result, high wear resistance and long-term maintenance of accuracy are achieved.

Stainless Steel Type also Available

A special type which LM block, LM rail and balls are made of stainless steel is also available.

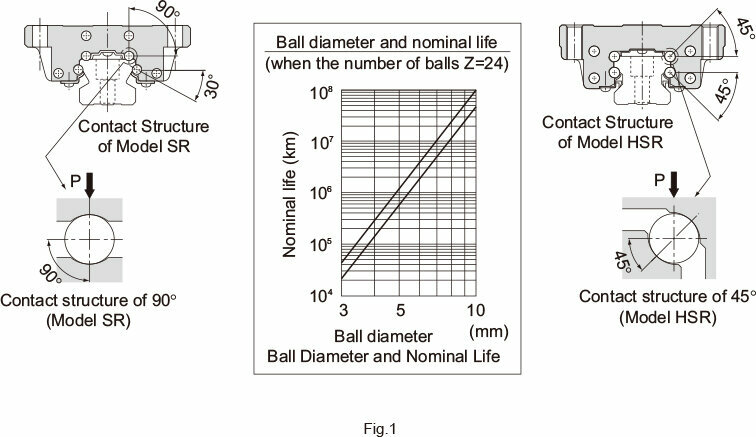

Characteristics of Model SR

When compared to models having a contact angle of 45°, model SR shows excellent characteristics as indicated below. Using these characteristics, you can design and manufacture highly accurate and highly rigid machines or equipment.

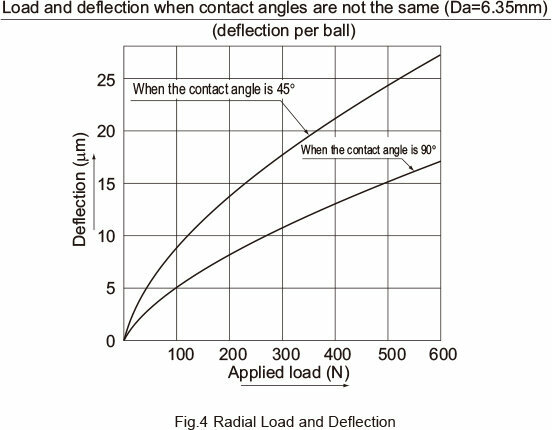

Difference in Rated Load and Service Life

Since SR has a contact angle of 90°, its rated load and service life are different from those with a contact angle of 45°. When comparing model SR with a model that has a contact angle of 45° and when the same radial load is applied to the two models with the same ball diameter as shown in the figure below, the load applied to SR is 70% of the other model. As a result, the service life of SR is more than twice that of the other model.

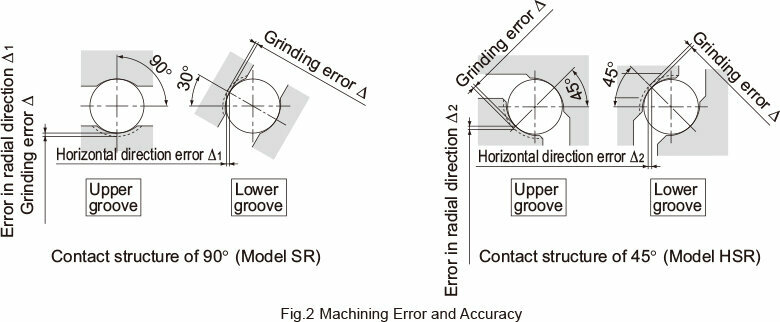

Difference in Accuracy

If a machining error (grinding error) occurs in the LM rail or LM block, it will affect the running accuracy. Assuming that there is a machining error of △ on the raceway, it results in an error in the radial direction, and the error with the contact angle of 45° (model HSR) is 1.4 times greater than that of the contact angle of 90° (model SR).As for the machining error resulting in horizontal direction error, the error with the contact angle of 45° is 1.22 times greater than the contact angle of 30° .

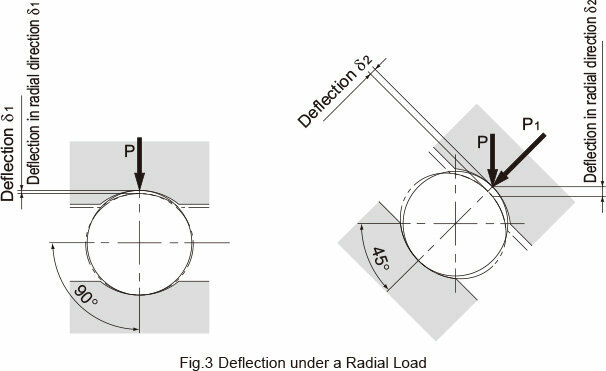

Difference in Rigidity

The 90° contact angle adopted by model SR has a difference with the 45° contact angle also in rigidity. When the same radial load "P" is applied, the displacement in the radial direction with model SR is only 56% of that with the contact angle of 45°. Accordingly, where high rigidity in the radial direction is required, model SR is more advantageous. The figure below shows the difference in radial load and displacement.

Conclusion

Model SR with this type of 90° contact construction are ideal for locations where the load applied is mostly radial, locations where radial rigidity is required, and locations where accurate motion is demanded in the up, down, left and right directions. However, if the reverse radial load, the lateral load or the moment is large, we recommend model HSR, which has a contact angle of 45° (4-way equal load).

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Length and Maximum Length of the LM Rail

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Tapped-hole LM Rail Type of Model SR

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |