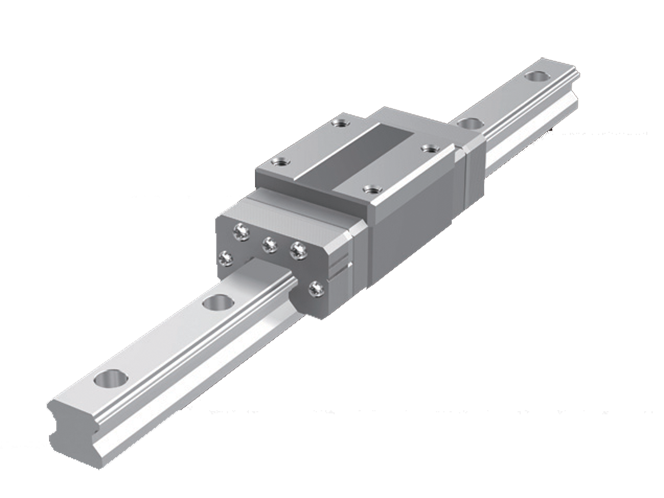

LM Guide Models for Special Environments Medium-to-Low Vacuum Model HSR-M1VV

Operable in various environments at pressure between atmospheric pressure and vacuum. Capable of withstanding baking temperature up to 200°C.

Size : 15

Types

Highlight feature tags

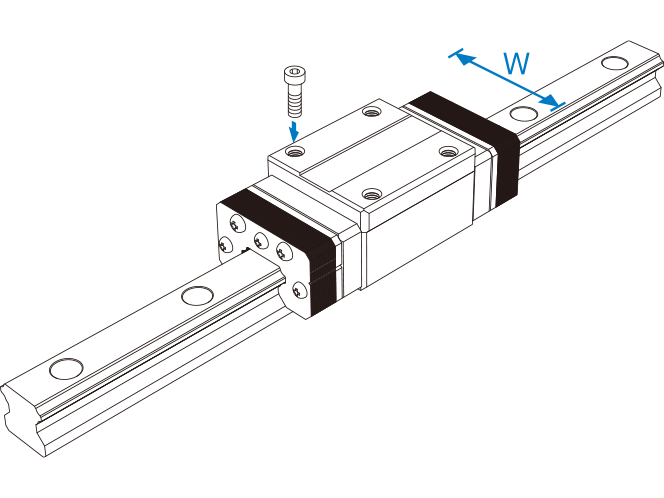

- Bolts mounted from above

- Bolts mounted from above

Basic load rating(kN) : Basic dynamic load rating 10.9 / Basic static load rating 15.7

Size :

15

Features

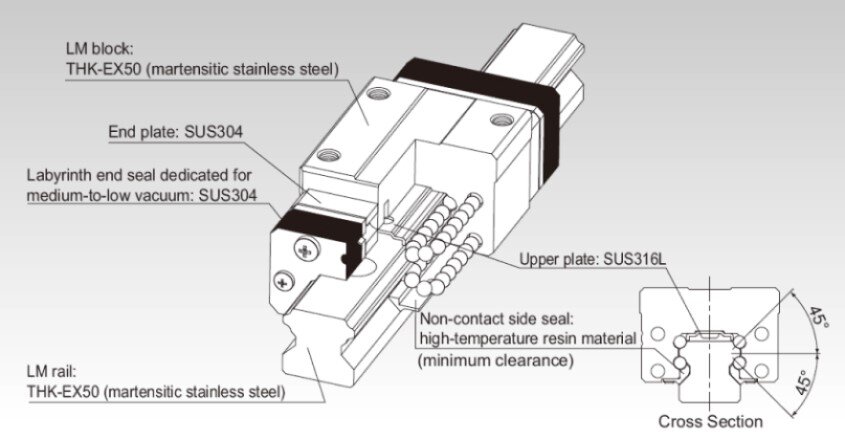

Structure and Features

Features

- Operable in various environments at pressure between atmospheric pressure and vacuum (10 -3 [Pa]).

- Capable of withstanding baking temperature up to 200°C *

- Use of a newly developed labyrinth end seal dedicated for Medium-to-Low Vacuum increases grease retention and allows extended use in vacuum.

- Use of grease designed for Medium-to-Low Vacuum achieves a stable rolling resistance.

* If the baking temperature exceeds 100°C, multiply the basic load rating with the temperature coefficient.

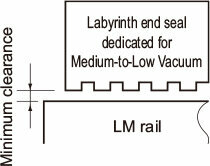

Structure of the labyrinth end seal dedicated for Mediumto-Low Vacuum

The labyrinth end seal dedicated for Medium-to-Low Vacuum forms a multi-stage space as shown in the figure on the right to minimize the pressure difference between adjacent stages. This reduces the out-flow velocity of the oil inside the LM block to a minimum. In addition, the seal will not affect the rolling resistance since it does not contact the LM rail.

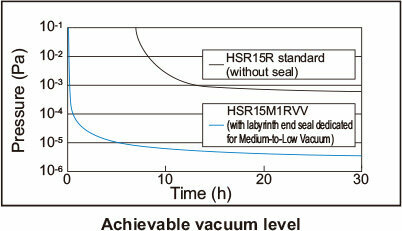

Achievable vacuum level

The LM Guide for Medium-to-Low Vacuum demonstrates an excellent achievable vacuum level.

[Test conditions] Temperature: 25°C (±5°C)

|

HSR15M1RVV |

HSR15R (for |

|

|---|---|---|

|

Grease |

Grease for Medium- |

AFB-LF Grease |

|

Seal |

Labyrinth end seal |

None |

|

Endplate |

Stainless steel |

Resin |

Achievable vacuum level

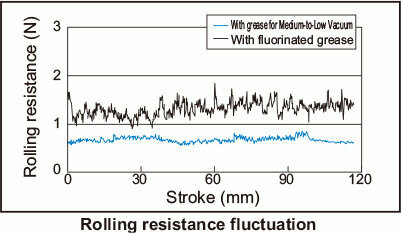

Rolling resistance

The grease used in the LM Guide for Medium-to-Low Vacuum has a smaller rolling resistance than conventional fluorine grease and ensures stable rolling motion.

Specimen: HSR15M1RVV

Temperature: 25°C (±5°C)

Pressure: atmospheric pressure

Rolling resistance fluctuation

Precautions on Design

If a large moment is applied to a system consisting of one LM rail or one LM block per shaft, the labyrinth end seal may contact the LM rail, which could affect the system’s motion. If a moment is applied, it is recommended to use two rails with two LM blocks per rail. Contact THK for details.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Lengths and Maximum Lengths of LM Rails

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |