AI Solution

for Linear Motion Components

AI Solution

for Rotary Components

suggestions

reports

Management System

AI Solution

for Cutting Tools

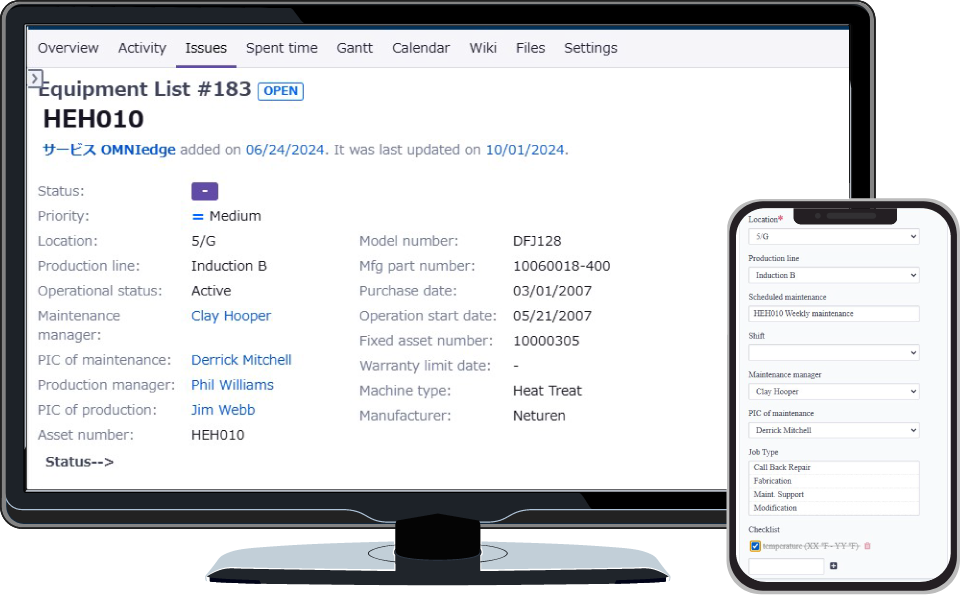

What is OMNI edge?

OMNI edge is a retrofittable IoT condition monitoring solution for predictive maintenance and reduction of losses that occur on the manufacturing floor, contributing to maximizing overall equipment effectiveness (OEE).

OMNI edge will continue to evolve, transforming the manufacturing industry.

Improve overall

equipment efficiency and

reduce losses with

OMNI edge!

There are many losses at production sites that impede efficiency.

Human Performance Losses

Five major losses

-

Management loss

- Motion loss

-

Organization loss

- Distribution/logistics loss

- Measurement and adjustment loss

-

Management loss

-

Organization loss

- Measurement and adjustment loss

- Motion loss

- Distribution/logistics loss

Equipment Availability Losses

Eight major losses

-

Cutting blade change loss

- Setting up and adjustment loss

- Speed loss

-

Defects and rework loss

- Startup loss

- Shutdown loss

Resource Consumption Losses

Three major losses

- Yield loss

-

Energy loss

- Die and tool loss

- Yield loss

- Die and tool loss

-

Energy loss

Sixteen major losses that hinder efficiency at production sites

Solve challenges facing the manufacturing industry with a retrofittable IoT condition monitoring solution!

Many manufacturing devices are in operation right now at factories all over the place.

In order to make these devices more efficient,

THK is transforming the manufacturing industry with a retrofittable IoT condition monitoring solution!

-

Management loss

- Motion loss

-

Organization loss

- Distribution/logistics loss

- Measurement and adjustment loss

-

Cutting blade change loss

-

Defects and rework loss

- Setting up and adjustment loss

- Startup loss

- Speed loss

- Shutdown loss

- Yield loss

-

Energy loss

- Die and tool loss

-

Management loss

- Motion loss

-

Minor stoppage and idling loss

-

Organization loss

-

Cutting blade change loss

- Distribution/

logistics loss -

Defects and rework loss

- Measurement and adjustment loss

- Setting up and adjustment loss

- Yield loss

- Startup loss

-

Energy loss

- Speed loss

- Die and tool loss

- Shutdown loss

Human

efficiency

Equipment

efficiency

Energy

efficiency

Contact THK for a consultation and detailed pricing.

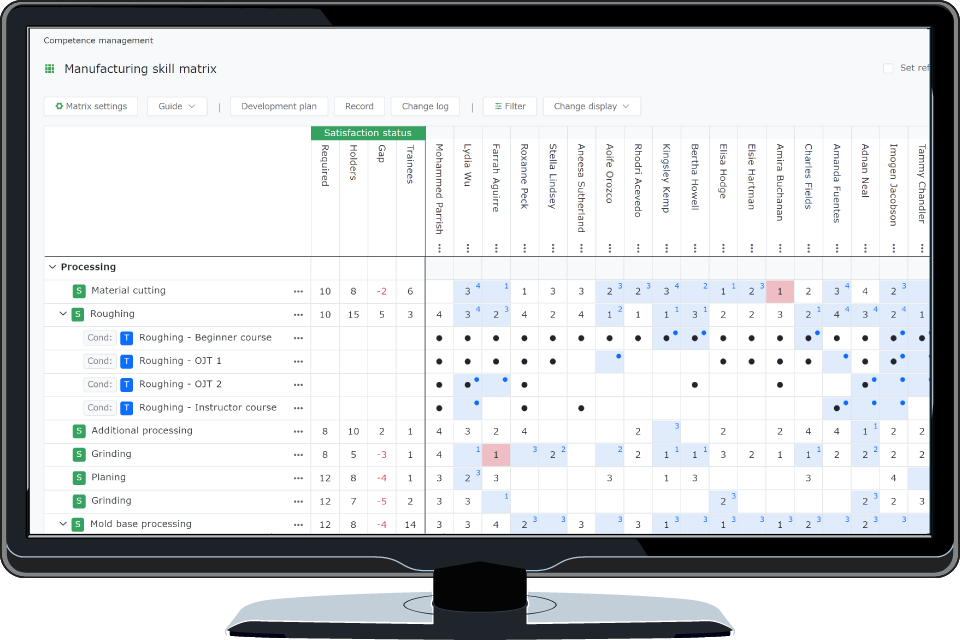

AI Solution

Management Tool

Support available before and after installation

Extensive support structure

We listen to the challenges you face and help establish goals and necessary steps for IoT implementation.

After implementation, we help you expand the service to other production lines and plants around the world.

Maximizing overall equipment effectiveness (OEE)

OMNIedge will expand into areas beyond predictive failure detection for components and provide solutions that can contribute to maximizing OEE.

Application Examples

OMNIedge is trusted by a wide range of customers!

News

Visit the Newsroom- Press release The OMNIedge homepage has been updated.

- Linear motion AI Orders Officially Open for the "OMNIedge" Linear Component AI Diagnosis Service (ADV): Analytic Reports Provided on AI-Calculated Changes and Abnormalities in Machine Status without the Need to Set Threshold Values

- Rotary motion AI Orders Officially Open for "OMNIedge" IoT Service for Manufacturing's AI Diagnosis Service (ADV) for Rotary Components, in Which AI Predicts Rotary Component Abnormalities and Failures and Specifies Recommended Maintenance