Jul 5, 2023

products

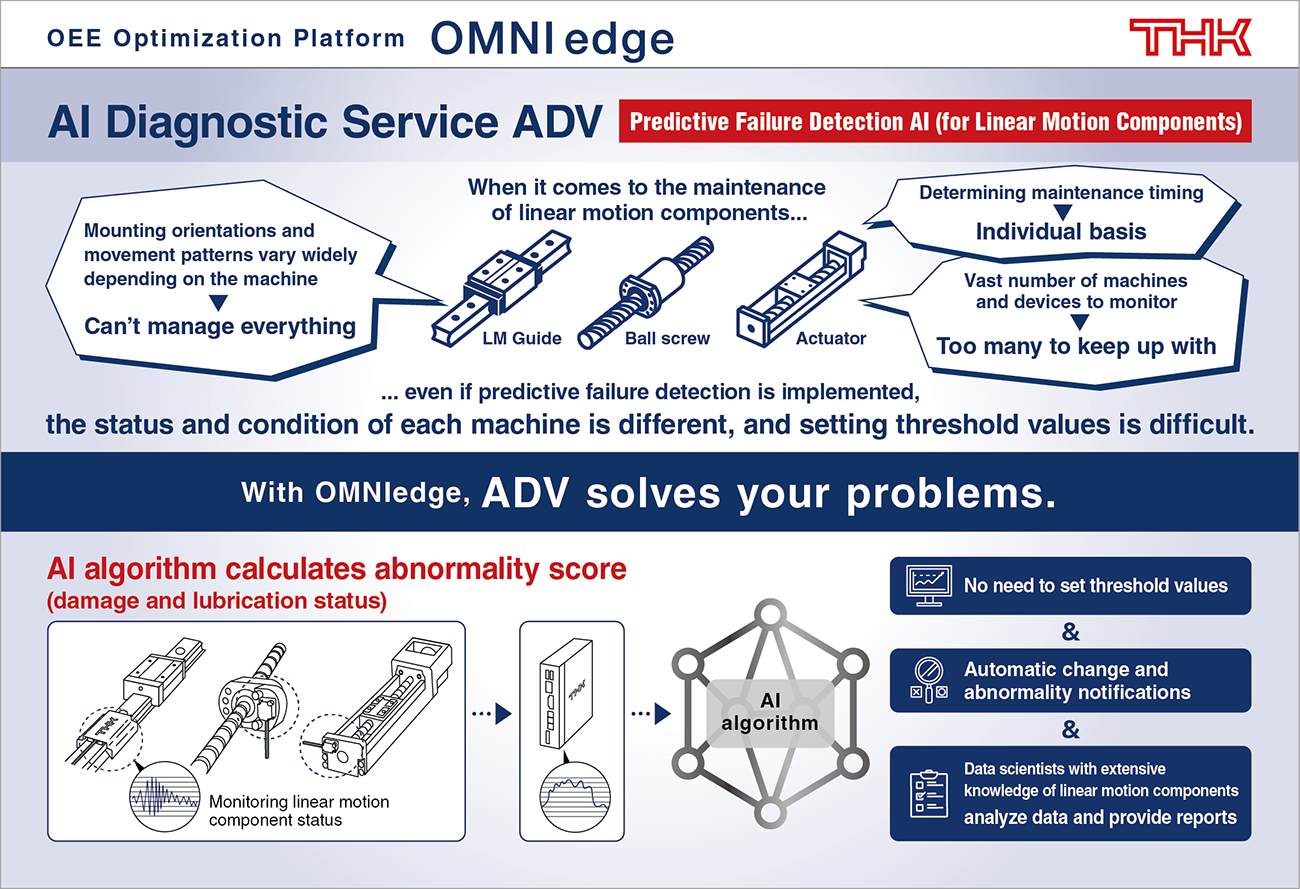

Orders Officially Open for the "OMNIedge" Linear Component AI Diagnosis Service (ADV): Analytic Reports Provided on AI-Calculated Changes and Abnormalities in Machine Status without the Need to Set Threshold Values

THK is now offering the brand-new AI Diagnostic Service (ADV) for the linear component version of its “OMNIedge” OEE optimization platform for the manufacturing industry.

The LM Guide, ball screws, and other linear motion components that are indispensable to the heart of manufacturing equipment are of high quality and high rigidity, and do not break down frequently. However, if they do break down suddenly, it causes extended downtime, resulting in significant production losses during factory operations. Although diligent maintenance such as periodic lubrication can help prevent failure, the more equipment and devices there are, the more preventive maintenance is required to prevent sudden failures that could seriously disrupt production. At the same time, while maintenance such as component replacement still relies on the experience and intuition of skilled technicians and is handled on an individual basis, there are many machine users that want to easily determine the timing of maintenance by making use of digital technology. Against this backdrop, THK has been providing a solution since 2020 to quantify damage and lubrication conditions by retrofitting sensors onto linear motion components, and it has now added the AI-based diagnostic service ADV.

An AI algorithm that calculates health scores is utilized for ADV, eliminating the traditional hassle of setting threshold values. These health scores (showing the degree of abnormality) are calculated based on various types of data to diagnose the condition of linear components. ADV not only detects changes and abnormalities, but also analyzes data and presents maintenance reports, dramatically improving the efficiency of the maintenance activities of customers who are responsible for the maintenance of many machines. In addition, when used in conjunction with the conventional function of quantifying the state of damage and lubrication, it also contributes to reducing dependence on individuals in diagnosing damage and maintenance timing for linear motion components.

THK is working to further strengthen engagement with customers by not just providing sensors, but also working on comprehensively providing a variety of services that utilize AI. Furthermore, THK will also provide IoT solutions for reducing loss that occurs on the manufacturing floor and contributing to maximizing overall equipment effectiveness (OEE).

Special Features of the AI Diagnostic Service (ADV) for Linear Components

No Need to Set Threshold Values

Threshold values used to have to be set for each parameter, but this is now unnecessary due to AI-calculated health scores.

ADV is the solution for customers who are struggling with setting threshold values for all of their machines.

Fusion of Digital and Analog

AI detects abnormalities based on changes in values, and specialists with extensive knowledge of linear motion components prepare and submit maintenance reports.

THK, the leading manufacturer of linear motion components, analyzes the data and provides reports, so they are clear and can be easily utilized.

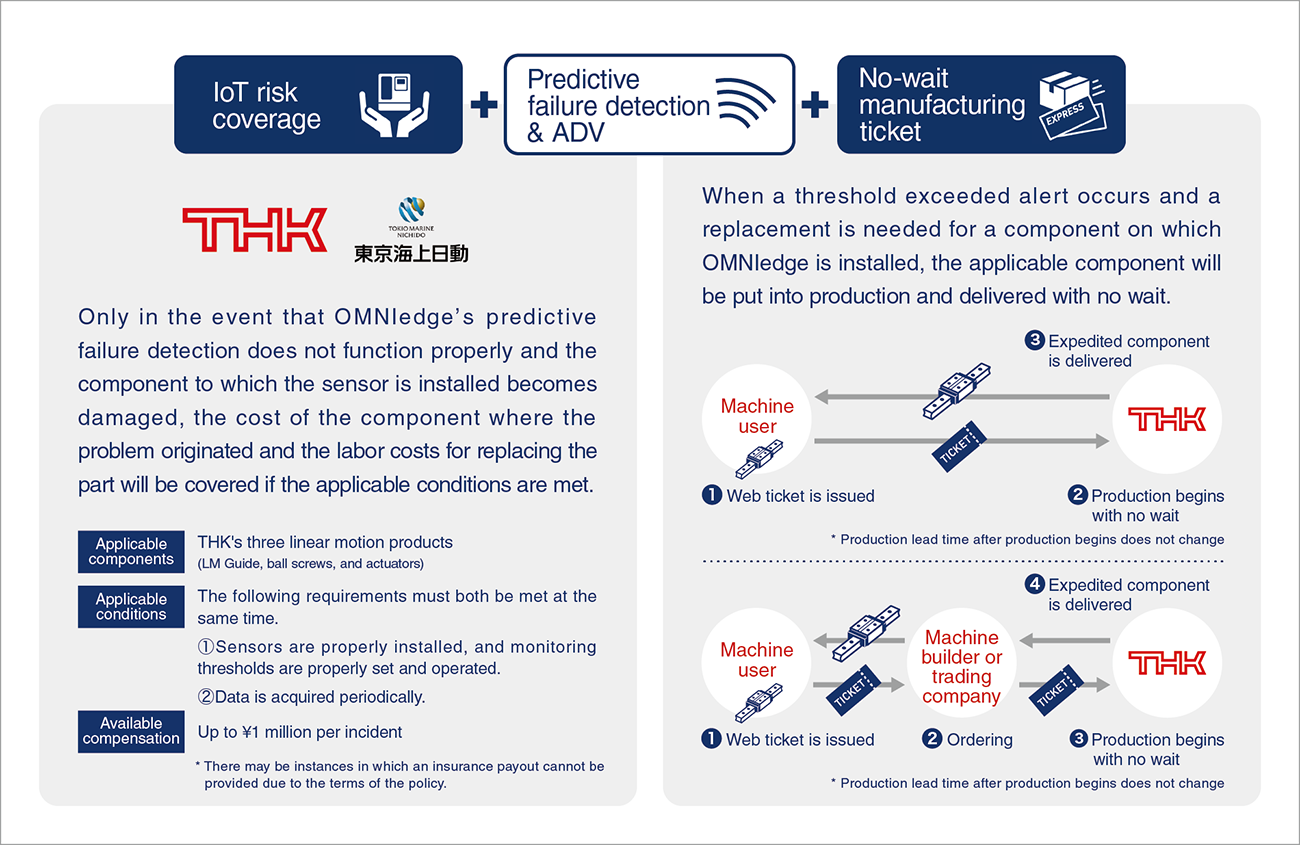

Two Peace-of-Mind Benefits Improved by the ADV AI Diagnostic Service

Meeting the conditions necessary for ADV utilization is above all a sign of solid operation, and when combined with the two peace-of-mind benefits of IoT risk coverage and no-wait manufacturing tickets, it creates a positive cycle that leads to an even greater sense of reassurance.

When an abnormal change is detected and replacement parts are needed, the waiting time can be reduced with no-wait manufacturing tickets, and if something goes wrong, predictive detection can be incorporated with IoT risk coverage to ensure a robust system.

OEE Optimization Platform OMNIedge

OMNIedge is an IoT solution service that reduces loss that occurs on the manufacturing floor and contributes to maximizing overall equipment effectiveness (OEE). This service combines the sensor and other hardware, a communication device, and the AI solution as a set package, making the service simple, secure, and available for a reasonable price.

Phase 1: Predictive failure detection AI solution for linear motion components (Long-awaited AI Diagnostic Service (ADV) available now)

Phase 2: Predictive failure detection AI solution for rotary components (AI Diagnostic Service (ADV) available)

Phase 3: Tool monitoring AI solution (available now)

Launch of AI Diagnostic Service (ADV)

July 2023

OMNIedge Website

https://www.thk.com/omniedge/en/

Related News

November 22, 2022 "OMNIedge” Now Provides a Tool Monitoring AI Solution that Detects Cutting Tool Damage and Wear to Reduce Loss

June 15, 2022 OMNIedge, an IoT Service for Manufacturing, Now Supports Private Cloud

February 2, 2022 OMNIedge, an IoT Service for Manufacturing, Now Provides Predictive Failure Detection for Rotary Components

November 9, 2021 Global SIM Compatibility for the “OMNIedge” IoT Service for Manufacturing Now Available in Taiwan and Singapore

July 19, 2021 Two Bonus Features Now Available to Add Peace of Mind to the “OMNIedge” IoT Service for Manufacturing

June 30, 2021 OMNIedge, an IoT Service for Manufacturing, Officially Launches in China

March 10, 2021 The “OMNIedge” IoT Service Now Available for Actuators

February 17, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry Now Connects with FIELD system: Bolstering the Service with Industrial

February 3, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry Goes Global: A New Service Compatible with Global SIM

November 16, 2020 The “OMNIedge” IoT Service for the Manufacturing Industry: Service Now Available for Ball Screws

Note) This information was originally released in Japanese on July 5, 2023.