LM Guide GK Series

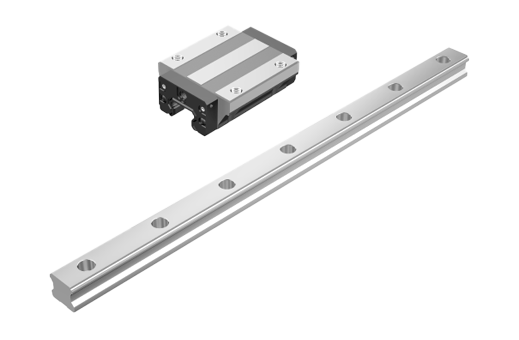

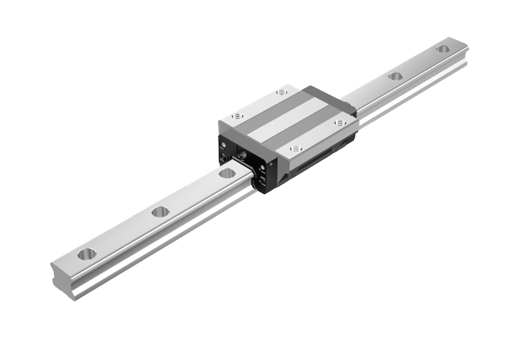

The LM Guide GK Series (interchangeable LM blocks and LM rails) includes LM blocks and LM rails that can be purchased separately. Because these products are interchangeable, customers can flexibly combine them to suit their needs.

Features of the GK Series

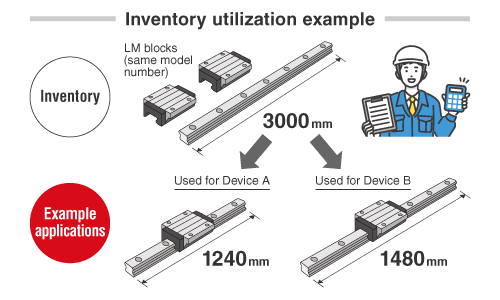

1. Consolidates inventory items for easier stock and purchase management

If you struggle with purchasing specific LM Guide products for each machine and managing all that inventory, the GK Series is the solution.

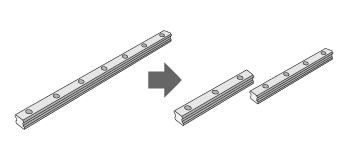

By purchasing individual GK Series LM blocks, you can maintain one collection of LM blocks that can be used on multiple machines. Similarly, ordering individual GK Series LM rails enables you to manage every rail under one item code in your inventory if the LM rails can be cut down to the size required for each machine.

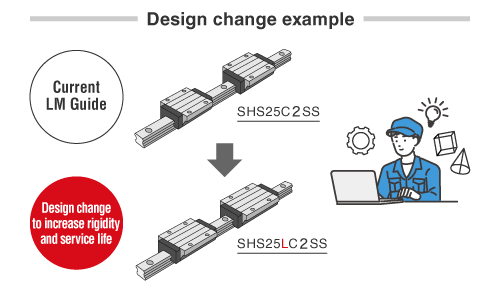

2. Makes design changes a breeze

GK Series LM blocks and LM rails with the same model number can be combined freely, meaning they can be used to enhance the rigidity and service life of an LM Guide found wanting in these categories during equipment design or after assembly simply by increasing radial clearance, block length, or block count per rail.

3. Easily replace parts when problems arise

When an LM block or LM rail needs to be replaced due to damage caused during assembly or because a purchasing mistake has turned into a part shortage, having a stock of interchangeable GK Series parts makes the process easy and minimizes equipment downtime.

GK Series (interchangeable) products vs. Set products

GK Series (interchangeable) products

Interchangeable parts make a number of things easier.

They’re limited in application, though, and the differences between parts can be considerable under certain conditions.

- Stock management is simplified through inventory consolidation.

- Radial clearance (preload*), block count, and block type can be changed.

- Damaged parts can easily be replaced with new ones.

Set products

Set products are composed of LM blocks and LM rails that come assembled together.

They have a wide range of applications and can satisfy specifications that are challenging for individually sold products.

- An extensive lineup of product types and accuracy grades is available.

- Customers can customize their products with special specifications.

- Pre-assembled products are easy to install.

* Radial clearance (preload) refers to the internal load applied in advance to the rolling elements (balls or rollers) in order to increase the LM block’s rigidity.

Use cases

Cutting rails to the required size for a given stroke pattern

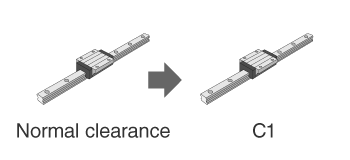

Changing to a block with a different radial clearance to increase rigidity

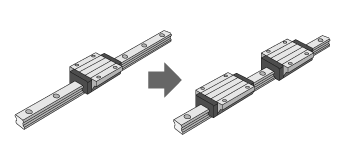

Adjusting load capacity by changing block count and block type

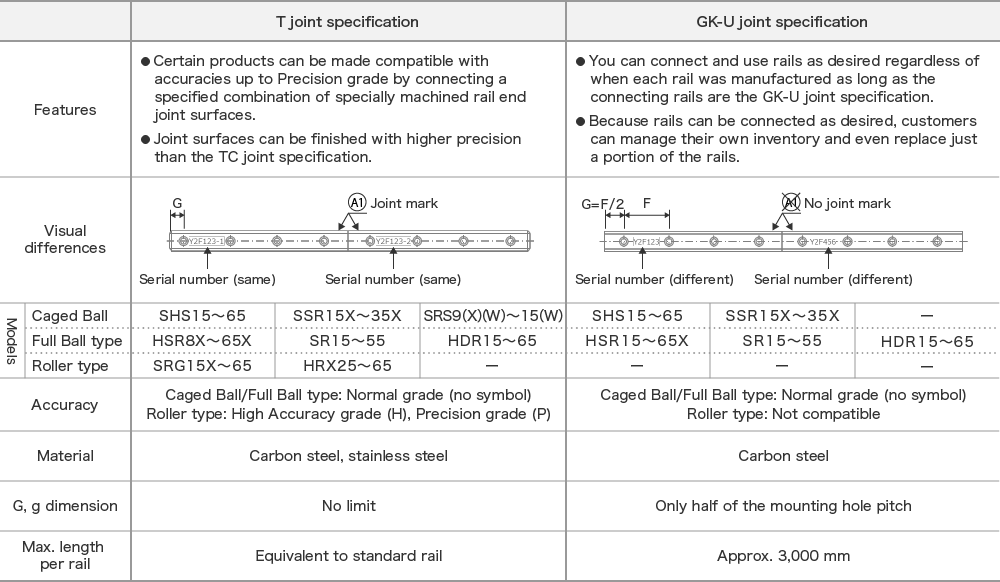

The difference between T joint specification and GK-U joint specification

The T joint specification and GK-U joint specification can accommodate long strokes that exceed the maximum rail length.

Usage Examples of GK-U Joint Specification

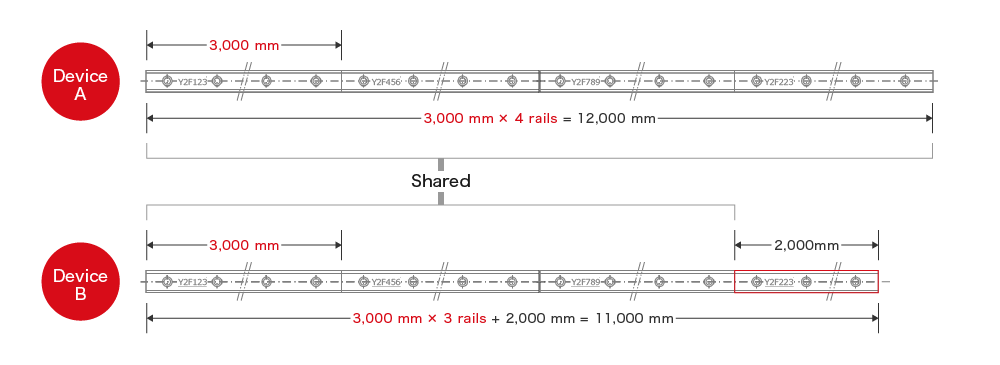

Example 1: Standardization of GK-U Joint Specification Rails

By combining GK-U joint specification rails, it is possible to reduce the variety of LM guides used across multiple devices.

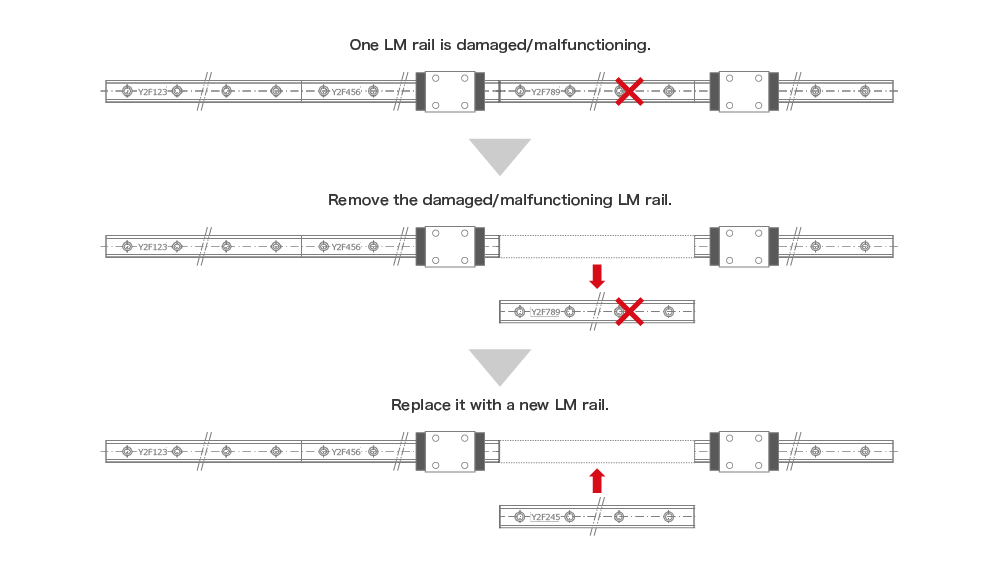

Example 2: Replacement of GK-U Joint Specification Rails

The GK-U joint specification allows for the replacement of rails.

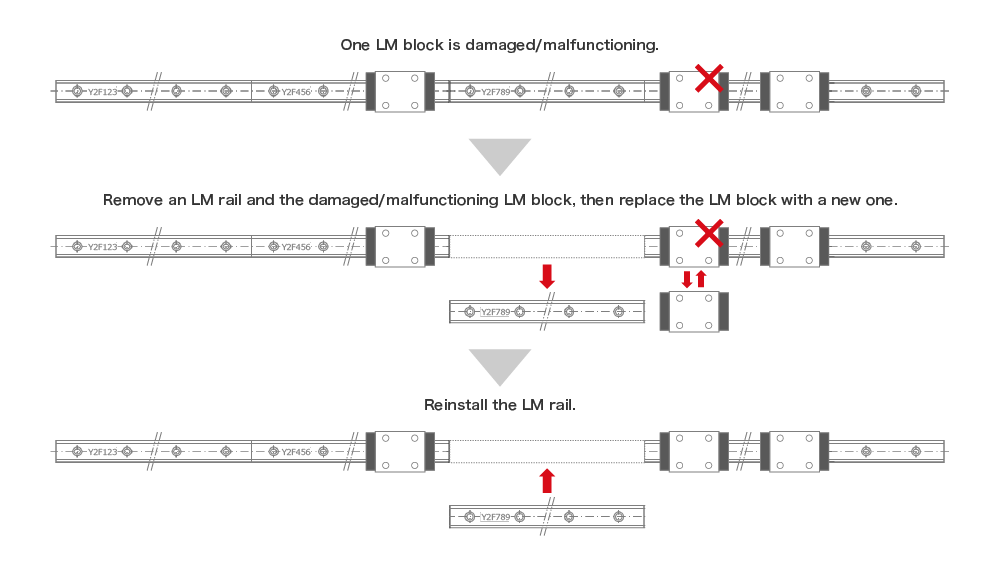

Example 3: Replacement of GK Blocks (Applicable to Both T Joint and GK-U Joint Specification Rails)

By removing a portion of the rail, it is possible to add or replace GK blocks.

Example Applications of Modular Design with the GK-U Specification

The T joint specification vs. the GK-U specification

T joint specification: Rails can only be connected in a specific combination.

GK-U specification: Rails with the same model number can be connected freely.

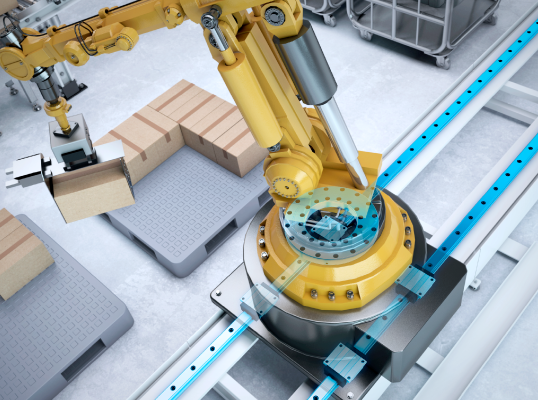

Articulated robot travel axis

- Flexibly combining base rails of set lengths makes it easy to extend or change the stroke.

- Base rail units can be stocked as inventory.

Automated Warehouse

- Connection specifications are possible even between multiple rails.

- Individual rails can be replaced one by one for repairs and maintenance.

Linear transfer equipment

Rails and tables (blocks) can be combined freely to fit the user’s specifications.

― Rails: Freely select the number and length of rails

― Blocks: Freely select the number of blocks

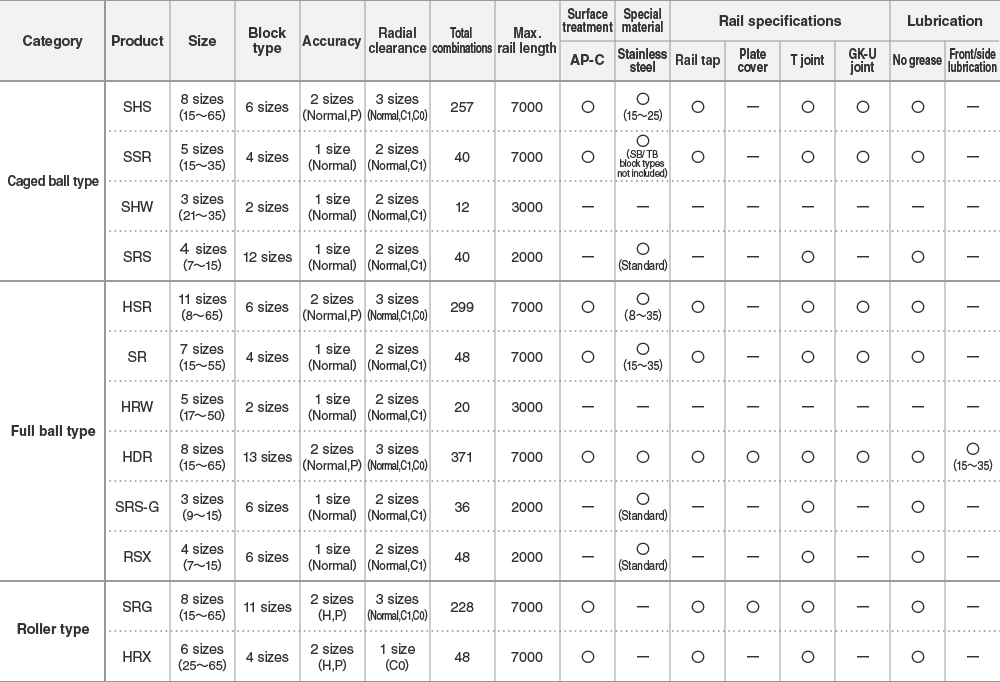

Product Lineup

Caged Ball Type

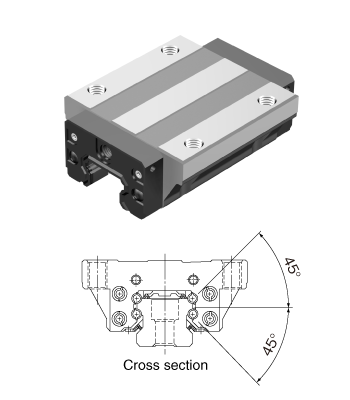

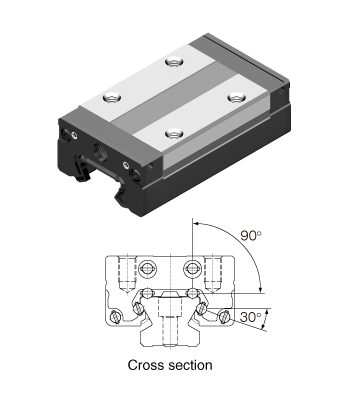

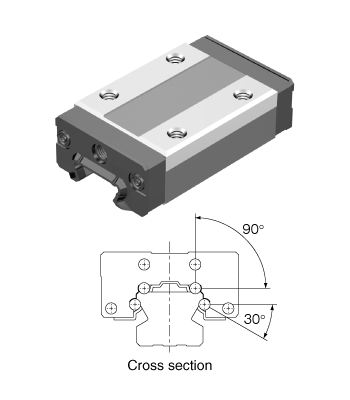

SHS

■ Features

- Globally standard dimensions

- Four-way equal load

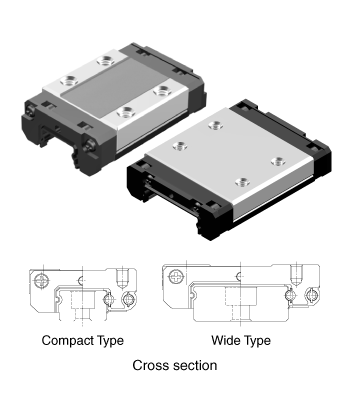

SSR

■ Features

- Compact

- Radial type

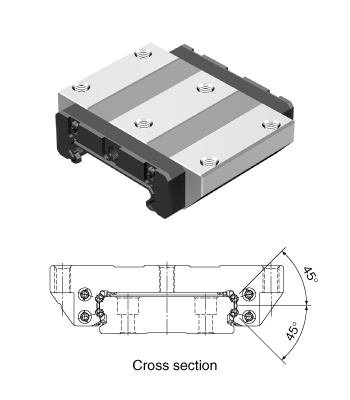

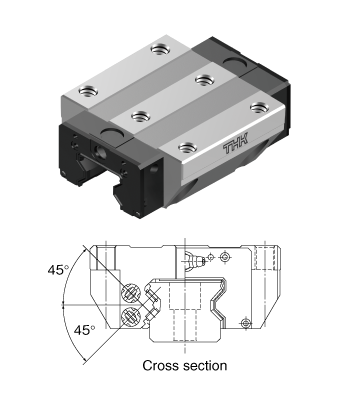

SHW

■ Features

- Low center of gravity

- Four-way equal load

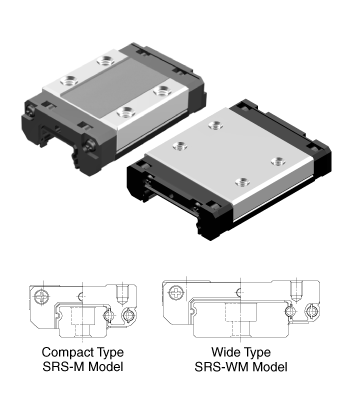

SRS

■ Features

- Miniature

- Four-way equal load

Full ball type

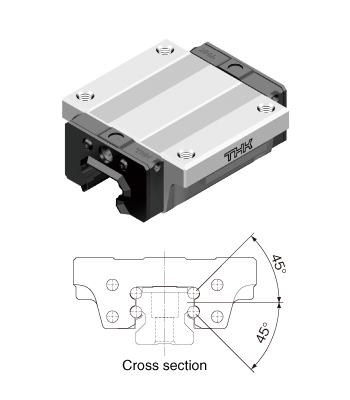

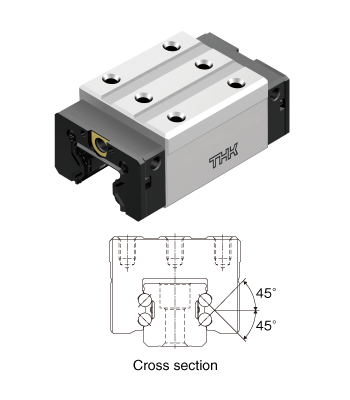

HSR

■ Features

- Global standard

- Four-way equal load

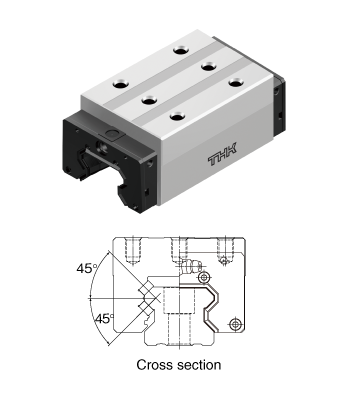

SR

■ Features

- Compact

- Radial type

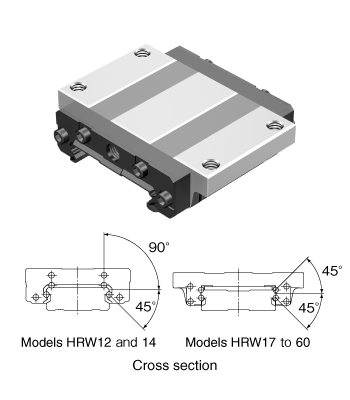

HRW

■ Features

- Low center of gravity

- For single-axis applications

SRS-G

■ Features

- Miniature

- Four-way equal load

RSX

■ Features

- Miniature

- Corrosion prevention

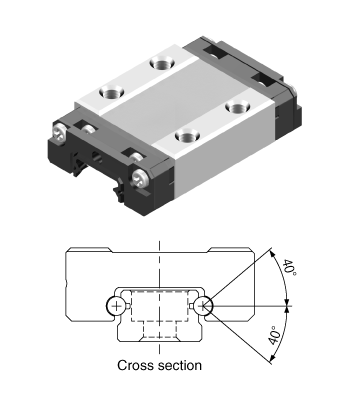

HDR

■ Features

- Four-way equal load

- For single-axis applications

Roller Type

HRX

■ Features

- Full-roller type

- Globally standard dimensions

- Four-way equal load

- Super-high rigidity

SRG

■ Features

- Roller retainer type

- Globally standard dimensions

- Four-way equal load

- Ultra-high rigidity

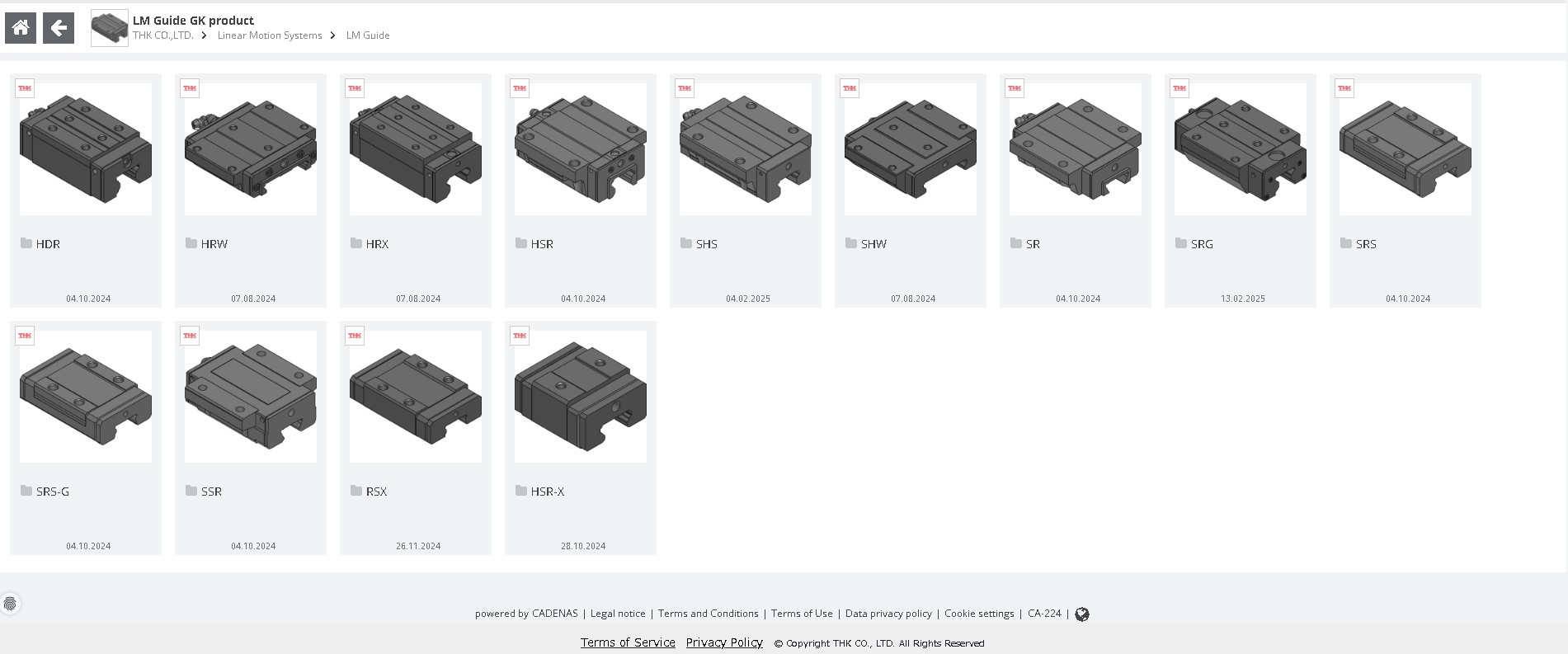

LM Guide GK Series Products

Click to expand.

Product lineups vary according to size, block type, and other specifications. See the Product Information page for details.

A Wide Array of Specification Options

Rail length

7m Single Rails Are Available in Stock!

Radial clearance (preload)

Normal/C1/C0

Accuracy grades

Normal grade/High Accuracy grade/Precision grade

Other selectable specifications

Surface treatment

Material

Lubrication specifications

Seal options

Rail options

Rail taps

See our catalog for more details.

Handling Precautions

Handling Precautions for T Joint and GK-U Joint Specifications

- When assembling T joint and GK-U joint specifications, there is a possibility of a step occurring at the joint section of the rails. Please exercise caution during assembly.

- T joint and GK-U joint specifications are different products; therefore, please refrain from combining them for use.

- The rail ends (joint surfaces) of the joint specifications are specially processed. If you use customer-processed cut surfaces as joint specifications, early damage may occur.

- The joint sections of LM rails are sharp and may cause injury. Please wear protective gloves to ensure safety.

- When inserting LM blocks into LM rails, there is a risk of damaging the lip section of optional parts. It is recommended to apply lubricant to the lip section and rail ends during insertion.

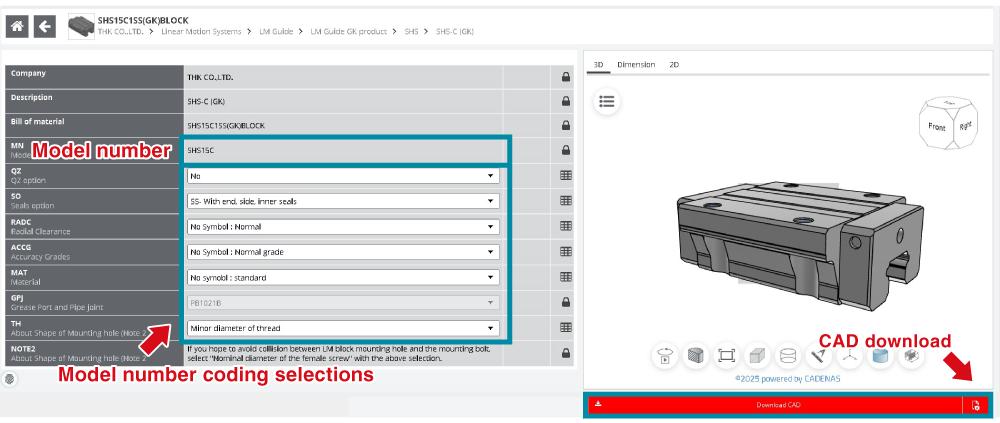

Easy Model Number Coding and CAD Downloads

Members registered with The THK Technical Support Site can see and select model number codes and CAD drawings.

Product selection screen

Model number coding and CAD download screen

FAQ

Q

Can Precision grade GK Series products be used for multi-axis (Mark II) applications?

A

Yes, they can be used this way. However, the specification value for the difference in height M between a pair for GK Series products with a multi-axis (Mark II or greater) specification is not the same as what it is for set products with this specification.

Q

Can GK Series products be combined with LM blocks and LM rails originally purchased as set products?

A

No, they cannot be used this way. Accuracy cannot be guaranteed if GK Series LM blocks or LM rails are combined with set products.

Q

Can GK Series LM blocks and LM rails with different accuracy grades be combined and used together?

A

No, they cannot be used this way. Accuracy cannot be guaranteed if GK Series LM blocks or LM rails with different accuracy grades are combined.

Q

Is the GK Series compatible with C caps?

A

Yes, C caps can be used with the GK Series.

Additional Resources

To view and use these resources, you must sign into a registered account for The THK Technical Support Site.

THK Online Store

Contact Us

Click below for assistance and questions related to the LM Guide GK Series.