Cross-Roller Ring

With the Cross-Roller Ring, cylindrical rollers are arranged with each roller perpendicular to the adjacent roller, in a 90° V groove, separated from each other by a spacer retainer. This design allows just one bearing to receive loads in all directions including radial, axial and moment loads.

Since the Cross-Roller Ring achieves high rigidity despite the minimum possible dimensions of the inner and outer rings, it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical equipment, measuring instruments and IC manufacturing machines.

Types

Highlight feature tags

- High rigidity

- Lightweight

- Thin type

- USP grade series

- Single split

- Separable outer ring type

- Two-piece inner ring type

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Large load capacity

- Rotation accuracy

- For robots

- With flange

- High rigidity

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Rotation accuracy

- High rigidity

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Rotation accuracy

- High rigidity

- Separable outer ring type

- Outer ring rotation

- Rotation accuracy

- High rigidity

- Two-piece inner ring type

- Inner ring rotation

- Rotation accuracy

- High rigidity

- USP grade series

- Separable outer ring type

- Outer ring rotation

- Rotation accuracy

- High rigidity

- USP grade series

- Two-piece inner ring type

- Inner ring rotation

- Rotation accuracy

- High rigidity

- Inner ring rotation

- Outer ring rotation

- Integrated inner / Outer ring type

- Rotation accuracy

- High rigidity

- Separable outer ring type

- Outer ring rotation

- Rotation accuracy

- High rigidity

- Single split

- Large load capacity

- Rotation accuracy

- Lightweight

- Outer ring rotation

- Thin type

- With flange

- Rotation accuracy

- For robots

Search products by various conditions

Features

Structure and Features

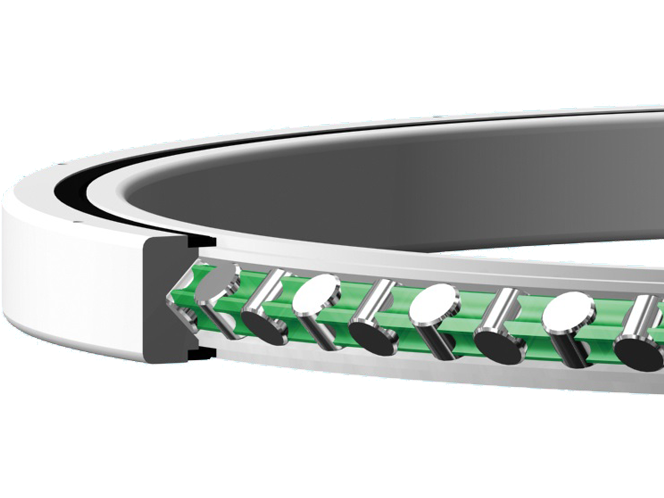

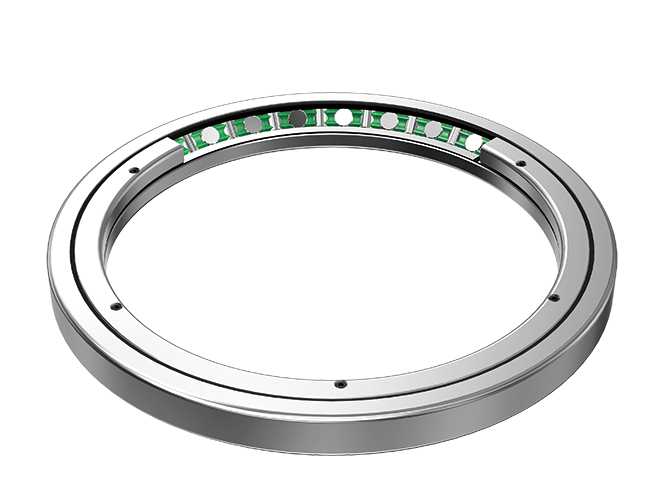

With the Cross-Roller Ring, cylindrical rollers are arranged with each roller perpendicular to the adjacent roller, in a 90° V groove, separated from each other by a spacer retainer. This design allows just one bearing to receive loads in all directions including radial, axial and moment loads. Since the Cross-Roller Ring achieves high rigidity despite the minimum possible dimensions of the inner and outer rings, it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical equipment, measuring instruments and IC manufacturing machines.

High Rotation Accuracy

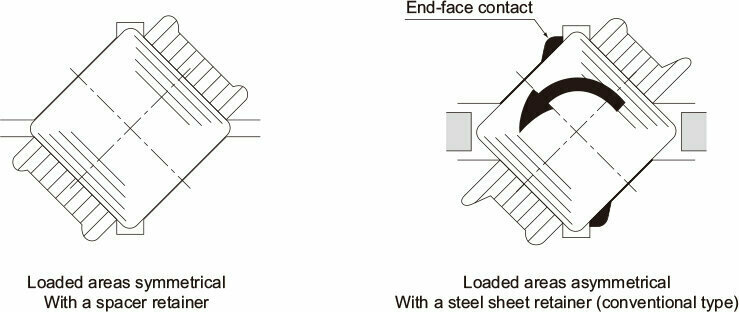

The spacer retainer fitting among cross-arrayed rollers prevents rollers from skewing and the rotational torque from increasing due to friction between rollers. Unlike conventional types using steel sheet retainers, the Cross-Roller Ring does not cause unilateral contact of roller or seize. Thus, even under a preload, the Cross-Roller Ring provides stable rotation. Since the inner and outer rings are designed to be separable, the preload can be adjusted, and this feature enables accurate rotation.

Easy Handling

The inner and outer rings, which are separable, are secured to the Cross-Roller Ring body after being installed with rollers and spacer retainers in order to prevent the rings from separating from each other. Thus, it is easy to handle the rings when installing the Cross-Roller Ring.

Skewing Prevention

The spacer retainer keeps rollers in their proper position, thereby preventing them from skewing (tilted rollers). This eliminates friction between rollers, and therefore secures a stable rotational torque.

Increased Rigidity (Three to Four Times Greater than the Conventional Type)

Unlike the thin angular ball bearings installed in double rows, the cross array of rollers allows a single cross-roller ring unit to receive loads in all directions, increasing the rigidity to three to four times greater than the conventional type.

Large Load Capacity

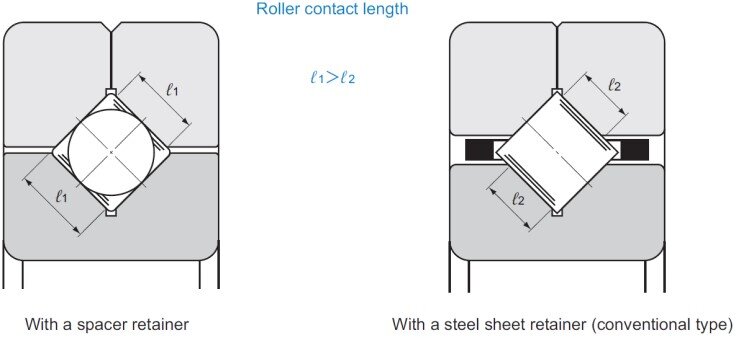

- Compared with conventional steel sheet retainers, the spacer retainer allows a longer effective contact length of each roller, thus significantly increasing the load capacity.

The spacer retainer guides rollers by supporting them over the entire length of each roller, whereas the conventional type of retainer supports them only at a point at the center of each roller. Such one-point contact cannot suffi ciently prevent skewing.

- In conventional types, the loaded areas are asymmetrical between the outer ring and the inner ring sides around the roller longitudinal axis. The greater the applied load is, the greater the moment becomes, leading end-face contact to occur. This causes frictional resistance, which hinders smooth rotation and quickens wear.