Static Safety Factor

The basic static load rating C0 refers to the static load with constant direction and magnitude, under which the calculated contact stress in the center of the contact area between the roller and the raceway under the maximum load is 4000 MPa. (If the contact stress exceeds this level, it will affect the rotation.) This value is indicated as "C0" in the specification tables. When a load is statically or dynamically applied, it is necessary to consider the static safety factor as shown below.

- * The minimum value for the static safety factor is based on the presumption of appropriate lubrication and optimal conditions for mounting and assembly. It is not possible to calculate the effect on internal loads that may be caused by improper mounting, deformation of mounting components, or the like. Please take all necessary action to ensure safety.

Calculating the Modified Nominal Life

The nominal life (L10) is obtained from the following formula using the basic dynamic load rating (C) and the load acting on the roller follower (PC ).

Calculating the Modified Nominal Life

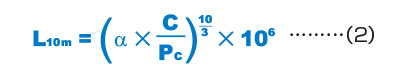

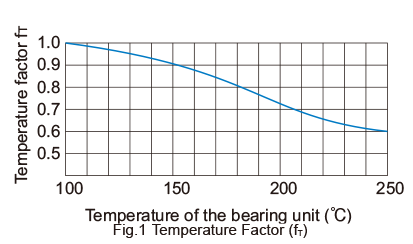

During use, a roller follower may be subjected to vibrations and shocks as well as fluctuating loads, which are difficult to detect. In addition, the operating temperature will have a decisive impact on the service life. Taking these factors into account, the modified nominal life (L10m) can be calculated according to the following formula (2).

Modifi ed factor α

Modified nominal life L10m

- * The basic dynamic load rating (C) of the roller follower shows the radial load under which the nominal life (L) is 1 million revolutions when a group of identical roller follower units independently operate, assuming a constant direction and magnitude of the load. This value is indicated in the specification tables.

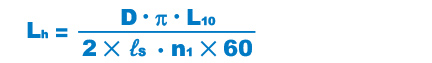

Calculating the Service Life Time

When the nominal life (L10) has been obtained, the service life time (Lh) is obtained from the following equation.

For Linear Motion

- Note) The normal service temperature is 80°C or below. If the product is to be used at a higher temperature, contact THK.

For Rotary Motion