- Workpiece

- Issue resolution

Introduction

With the increased automation of manufacturing facilities, the pick and place process for workpieces is very common.

In the conventional operations performed by human hands, the complex work process of grasping objects with hands or tweezers, confirming the parts visually, carrying them to the required location, and placing them in the optimal orientation is achieved with the precision machines that are human hands and the super high-performance control device that is the human brain.

So, what kind of processes can be replaced by the PPR?

In this article, we will show you which areas in manufacturing facilities have pick and place processes where the PPR may be able to make a contribution.

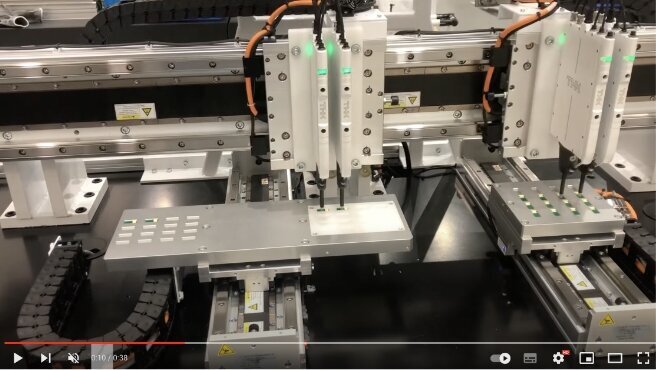

Representation of the PPR's Operation

Before introducing the processes, we would like to show you a video of a demo machine actually transferring workpieces using the PPR.

In this video, we are using our GLM series linear motor actuators for the XY axis. The workpiece is envisioned as a small plate and is transferred between trays. In the transfer process on the right, a 90-degree angle adjustment is also simultaneously performed.

Assembly Process / Mounting Process

So, what kind of facilities are there in actual manufacturing plants, and where can the PPR be used?

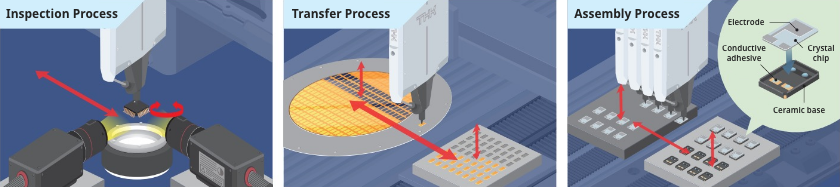

We envision the following three main processes.

Inspection Process

Visual inspection, current inspection, jig insertion, dimensional inspection, etc.

Used not only for direct inspection, but also for the transfer process by the loader/unloader to the inspection area.

Transfer Process

Possible scenarios may include so-called "tray to tray" for workpiece alignment and error classification, picking of diced semiconductor wafers, picking from randomly stacked workpieces, picking from conveyors, and picking of cut materials.

Assembly Process

A variety of processes are possible, such as:

Semiconductors: adhesion during die bonding and pressure bonding

Manufacturing of electronic components: mounting, pressing at a constant pressure, pressing down during curing, alignment adjustment on adhesives, solder pastes, etc.

Optical components: alignment with the optical axis

Board mounting: component mounting, component insertion, and light pressure fitting

If you have any ideas about how to implement a pick and place process in your work, please contact us, and we might be able to help you!

Our hope is to help our customers improve their processes.