Caged Roller LM Guide

The Caged Roller LM Guide is a roller guide that achieves low friction, smooth motion, and long-term maintenance-free operation by using a roller cage. In addition, rollers with optimized lengths and diameters have been utilized as the rolling elements in order to minimize elastic deformation and achieve ultra-high rigidity. Furthermore, the lines of rollers are placed at a contact angle of 45° so that the same rated load is applied in all (radial, reverse-radial, and horizontal) directions.

Types

Highlight feature tags

- Long-term maintenance free

- High rigidity

- Super-rigid

- Ultra-rigid

- High accuracy

- Heavy load

- Super-heavy load

- Low-profile LM Guide

- Low friction

- 4-way equal load

- Wide

- Ultra-heavy load

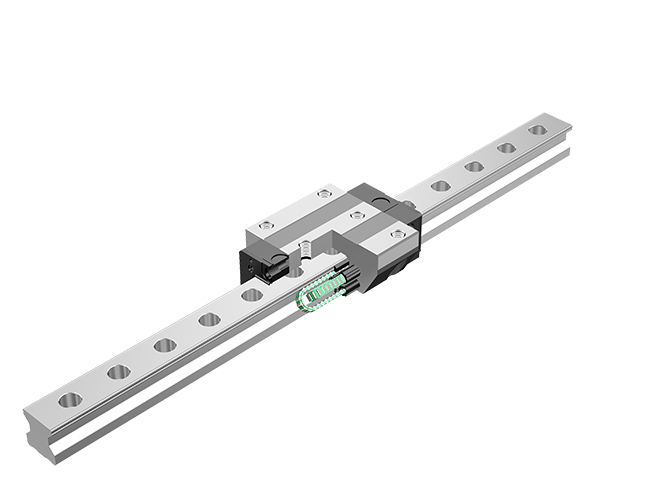

- Long-term maintenance free

- High rigidity

- Super-rigid

- Ultra-rigid

- High accuracy

- Heavy load

- Super-heavy load

- Ultra-heavy load

- Low friction

- 4-way equal load

Size : 15,20,25,30,35,45,55,65,85,100

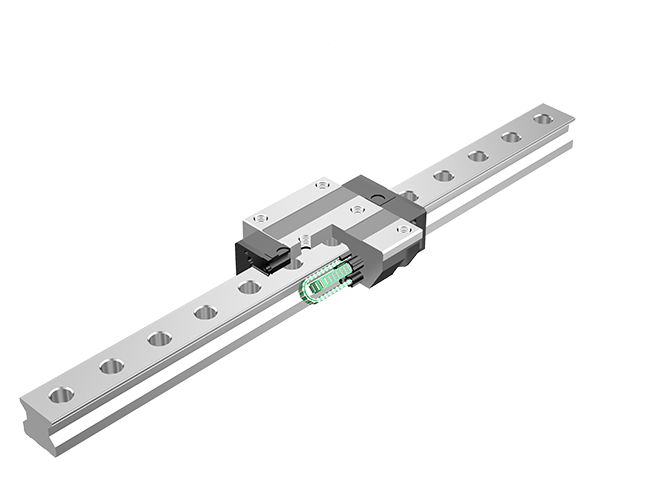

- Long-term maintenance free

- High rigidity

- Super-rigid

- Ultra-rigid

- High accuracy

- Heavy load

- Super-heavy load

- Ultra-heavy load

- Low-profile LM Guide

- Low friction

- 4-way equal load

Size : 35,45,55,65

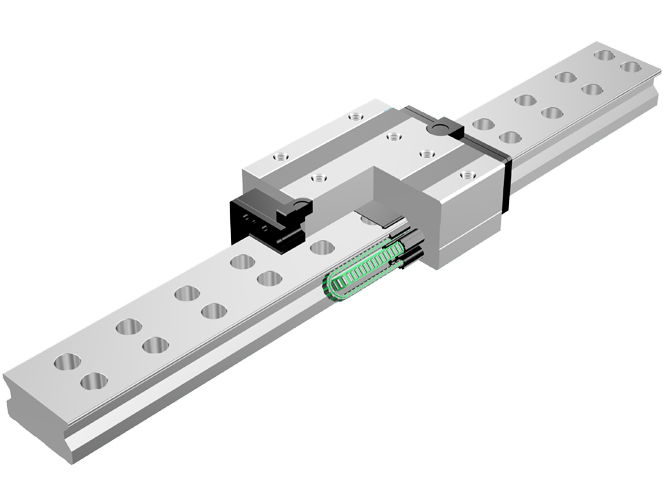

- Long-term maintenance free

- High rigidity

- Super-rigid

- Ultra-rigid

- High accuracy

- Heavy load

- Super-heavy load

- Ultra-heavy load

- Low-profile LM Guide

- Low friction

- 4-way equal load

- Wide

Size : 70,85,100,130,150

Features

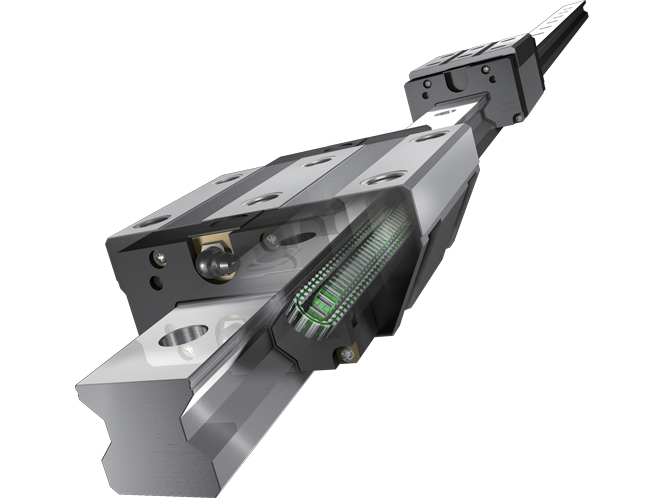

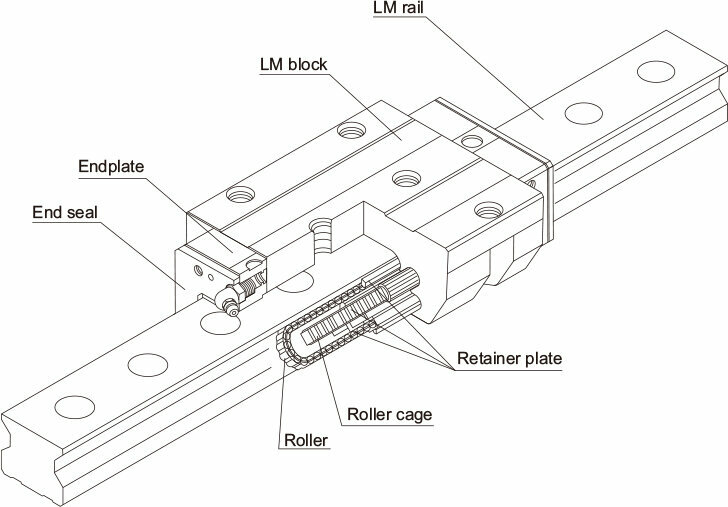

Structure and Features of the Caged Roller LM Guide

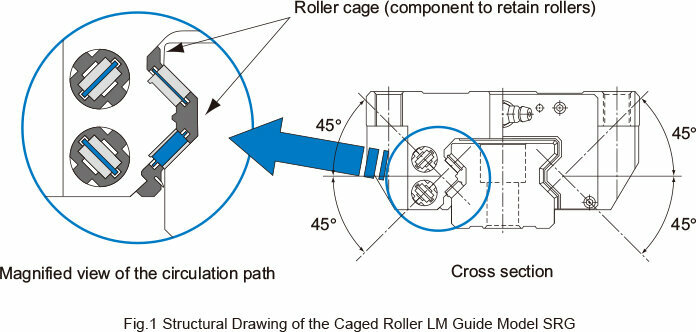

Caged Roller LM Guide is a roller guide that achieves low-friction, smooth motion and long-term maintenance-free operation by using a roller cage. In addition, to ensure ultra-high rigidity, rollers with low elastic deformation are used as the rolling elements and the roller diameter and the roller length are optimized.Furthermore, the lines of rollers are placed at a contact angle of 45° so that the same rated load is applied in all (radial, reverse and lateral) directions.

Advantages of the Caged Roller Technology

- Evenly arranged rollers circulate in a way that limits the front-to-back and side-to-side movements of the rollers, preventing the rollers from skewing and minimizing rolling resistance fluctuations. The end result is smooth and stable motion.

- The absence of friction between rollers and the retention of lubrication in grease pockets enable long-term maintenance-free operation.

- The absence of friction between rollers achieves low heat generation and superbly high speed.

- The absence of roller-to-roller collision ensures low noise and acceptable running sound.

Smooth Motion

● Rolling Resistance Data

Evenly spaced and aligned rollers circulate, minimizing rolling resistance fluctuations and achieving smooth and stable motion.

[Conditions]

- Feeding speed10mm/s

- Applied loadno load (one block)

Long-term Maintenance-free Operation

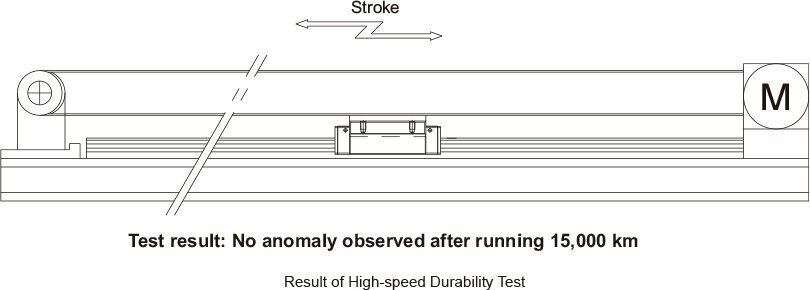

● High-speed Durability Test Data

Use of a roller cage eliminates friction between rollers, minimizes heat generation and increases grease retention, thus to achieve long-term maintenance-free operation.

[Conditions]

- Model No.SRG45LC

- Magnitude of preloadclearance C0

- Speed180m/min

- Acceleration1.5G

- Stroke2300mm

- LubricationInitial lubrication only

(THKAFB-LF Grease)

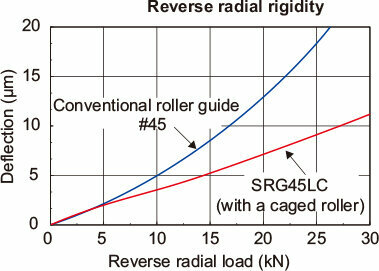

Ultra-high Rigidity

● High Rigidity Evaluation Data

[Preload]

- SRGradial clearance C0

- Conventional typeradial clearance equivalent to C0

Radial rigidity

Reverse radial rigidity

Horizontal rigidity

Rigidity is measured with the two axes placed in parallel and one of the axes not fixed with a bolt in order not to apply a moment.