Caged Roller LM Guide Ultra-high Rigidity (Wide) Model SRW

As a result of increasing the width of the Roller Guide, the mounting strength and mounting stability are increased.

Size : 70,85,100,130,150

Types

Highlight feature tags

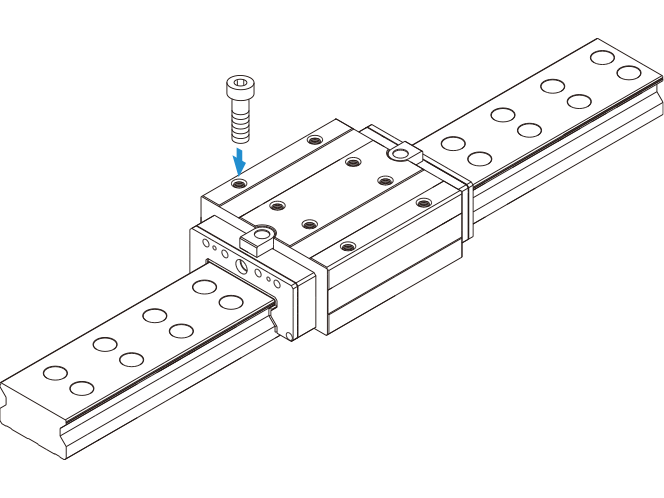

- Bolts mounted from above

- Bolts mounted from above

Basic load rating(kN) : Basic dynamic load rating 115 to 601 / Basic static load rating 256 to 1170

Size :

70,85,100,130,150

Features

Structure and Features

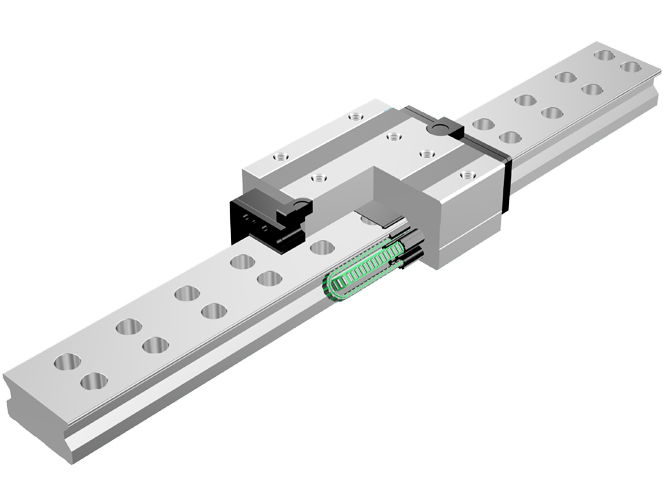

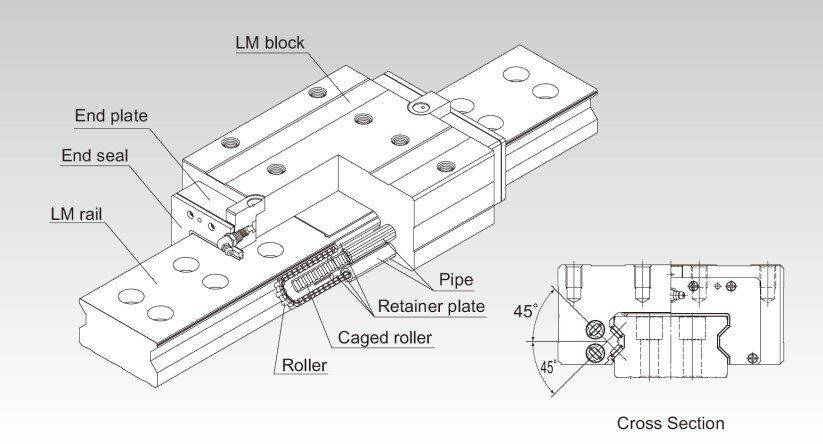

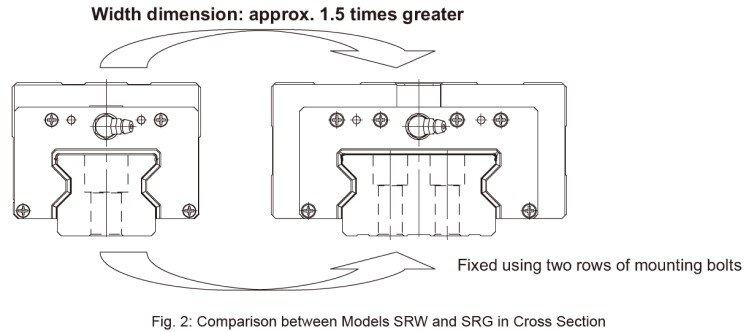

Based on Caged Roller LM Guide model SRG, this model has a wider rail and two rows of LM rail mounting holes to achieve high mounting strength and mounting stability. SRW is an ultra-high rigidity Roller Guide that uses roller cages to allow low-friction, smooth motion and achieve long-term maintenance-free operation.

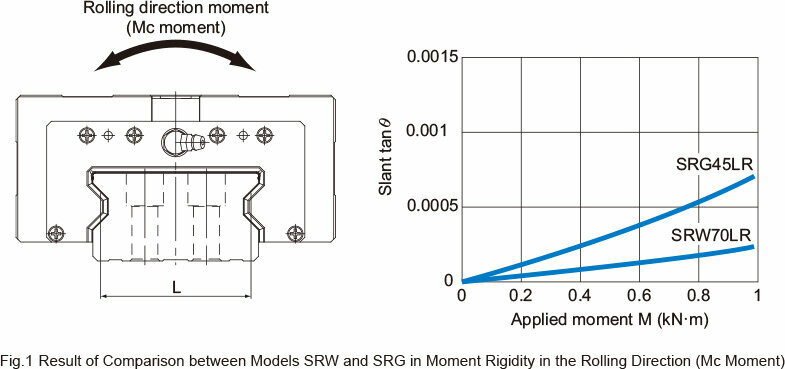

Ultra-high Rigidity

Since it has a wide rail and can be secured on the table using two rows of mounting bolts, the mounting strength is significantly increased. In addition, since the crosswise raceway distance (L) is large, model SRW is structurally strong against a moment load (Mc moment) in the rolling direction.Furthermore, model SRW uses rollers that show little elastic deformation as its rolling elements, and the overall length of each roller is 1.5 times greater than the diameter, thus to increase the rigidity.

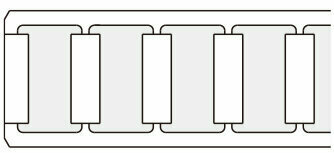

Smoothness Achieved through Skewing Prevention

The roller cage allows rollers to form an evenly spaced line while circulating, thus preventing the rollers from skewing as the block enters an loaded area. As a result, fluctuation of the rolling resistance is minimized, and stable, smooth motion is achieved.

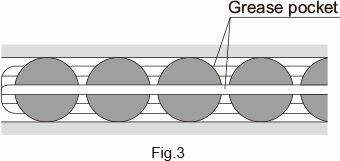

Long-term Maintenance-free Operation

Use of the roller cage eliminates friction between rollers and enables the lubricant to be retained in grease pockets formed between adjacent rollers. As the rollers circulate, the grease pocket serves to provide the required amount of lubricant to the contact curvature of the spacer and the roller, thus to achieve long-term maintenance-free operation.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Length and Maximum Length of the LM Rail

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |