Designing a Mounting Surface

Designing a Mounting Surface

If particularly high accuracy is required for the machine to which an LM Guide is to be mounted, it is necessary to mount the LM rail with high accuracy. To achieve the desired accuracy, be sure to design the mounting surface while taking the following points into account.

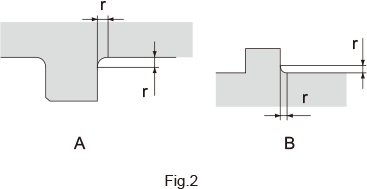

Corner Shape

If the corner on the surface on which the LM rail or LM block is to be mounted is machined to be shaped R, which is greater than the chamfer dimension of the LM rail or LM block, then the rail or the block may not closely contact its reference surface. Therefore, when designing a mounting surface, it is important to carefully read the description on the "corner shape" of the subject model . ( Fig.2 )

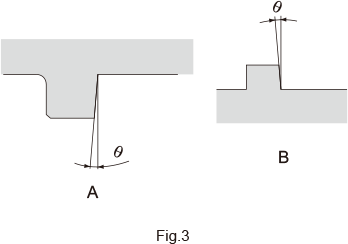

Perpendicularity with the Reference Surface

If the perpendicularity between the base mounting surface for the LM rail or the LM block and the reference surface is not accurate, the rail or the block may not closely contact the reference surface. Therefore, it is important to take into account an error of the perpendicularity between the mounting surface and the reference surface . ( Fig.3 )

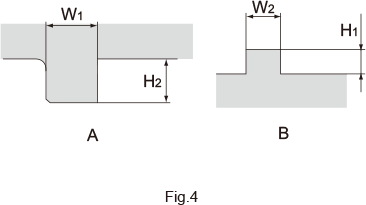

Dimensions of the Reference Surface

When designing the reference surface, be sure to take into account the height and the thickness of the datum area. If the datum area is too high, it may interfere with the LM block. If it is too low, the LM rail or the LM block may not closely contact the reference-surface depending on the chamfer of the rail or the block. Additionally, if the datum area is too thin, the desired accuracy may not be obtained due to poor rigidity of the datum area when a lateral load is applied or when performing positioning using a lateral mounting bolt . ( Fig.4 )

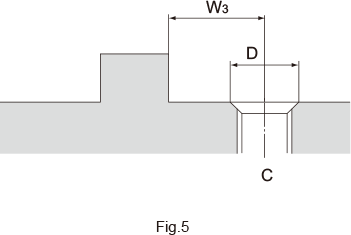

Dimensional Tolerance between the Reference Surface and the Mounting Hole

If the dimensional tolerance between the reference surface of the LM rail or the LM block and the mounting hole is too large, the rail or the block may not closely contact the reference surface when mounted on the base. Normally, the tolerance should be within ±0.1 mm depending on the model. ( Fig.5 )

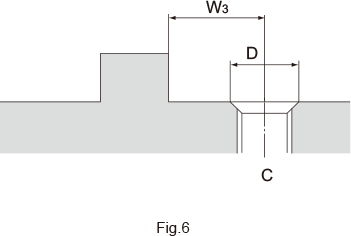

Chamfer of the Tapped Mounting Hole

To mount the LM rail, the mounting surface needs to be tapped and the tapped hole has to be chamfered. If the chamfer of the tapped hole is too large or too small, it may affect the accuracy . ( Fig.6 )

Guidelines for the chamfer dimension: Chamfer diameter D = nominal diameter of the bolt + pitch

Example: Chamfer diameter D with M6 (pitch): D = 6 + 1 = 7

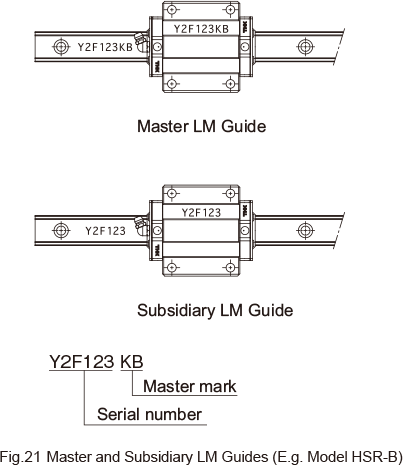

Marking on the Master LM Guide and Combined Use

Marking on the Master LM Guide

All LM rails mounted on the same plane are marked with the same serial number. The LM rail marked with "KB" after the serial number is the master LM rail. The LM block on the master LM rail has its reference surface finished to a designated precision, allowing it to serve as the positioning reference for tables. (See Fig.21 ) Normal grade LM Guides are not marked with "KB." Therefore, any one of the LM rails having the same serial number can be used as the master LM rail.

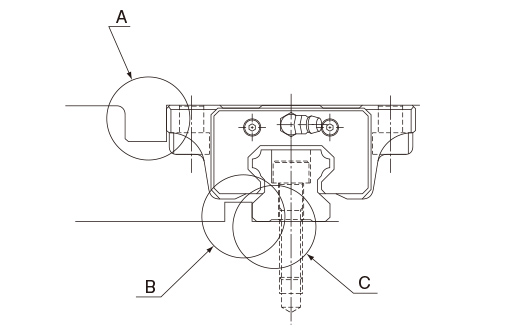

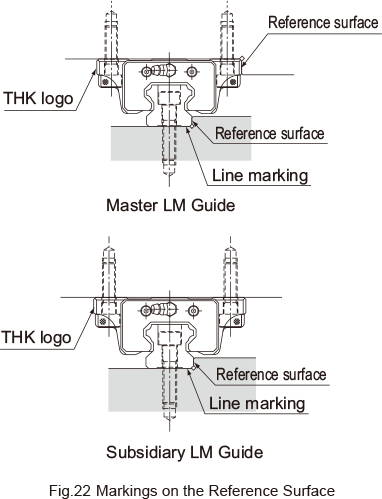

Markings on the Reference Surface

In the LM Guide, the reference surface of the LM block is opposite the surface marked with the THK logo, and that of the LM rail is on the surface marked with a line (see Fig.22 ). If it is necessary to reverse the reference surface of the LM rail and block, or if the grease nipple must be oriented in the opposite direction, specify it.

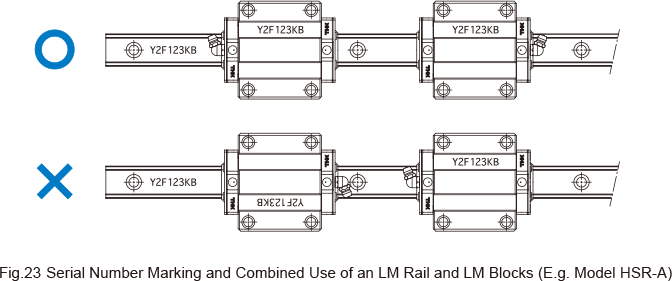

Serial Number Marking and Combined Use of an LM Rail and LM Blocks

An LM rail and LM block(s) used in combination must have the same serial number. When removing an LM block from the LM rail and reinstalling the LM block, make sure that they have the same serial number and the numbers are oriented in the same direction. ( Fig.23 )

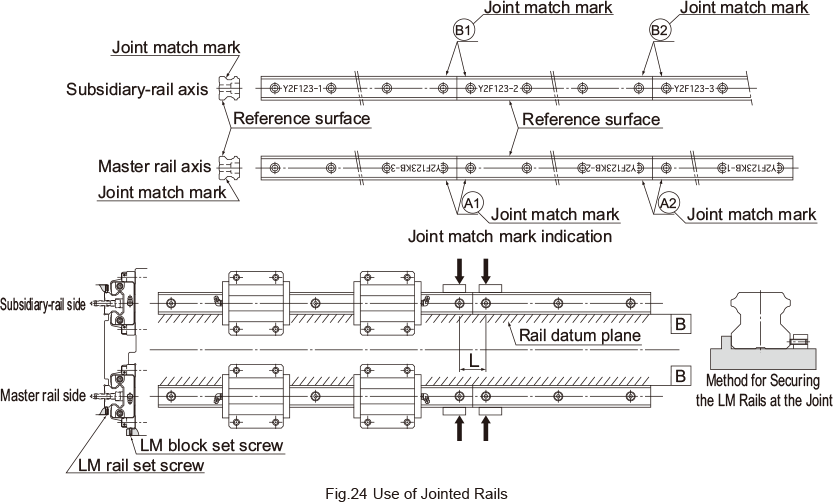

Use of Jointed Rails

When a long LM rail is ordered, two or more rails will be jointed together to the desired length. When jointing rails, make sure that the joint match marks shown in Fig.24 are correctly positioned. When two LM Guides with connected rails are to be arranged in parallel to each other, the two LM Guides will be manufactured so that the two LM Guides are axisymmetrically aligned.