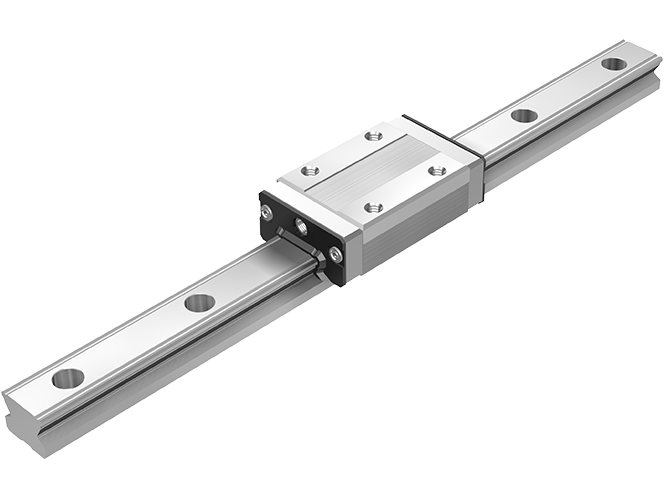

LM Guide Models for Special Environments High-Temperature Model SR-M1

A highly corrosion resistant LM Guide that achieves a maximum service temperature of 150℃.

Size : 15,20,25,30,35

Types

Highlight feature tags

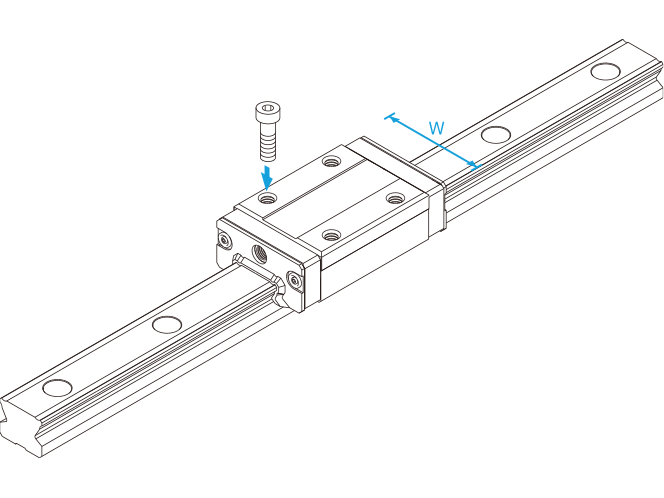

- Flange

- Bolts mounted from above

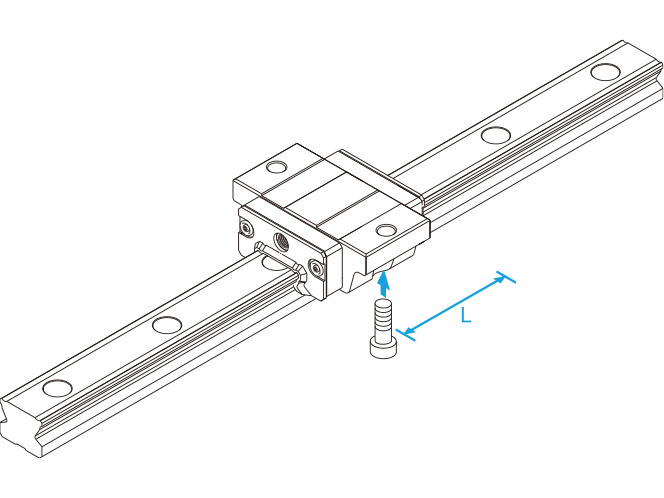

- Bolts mounted from below

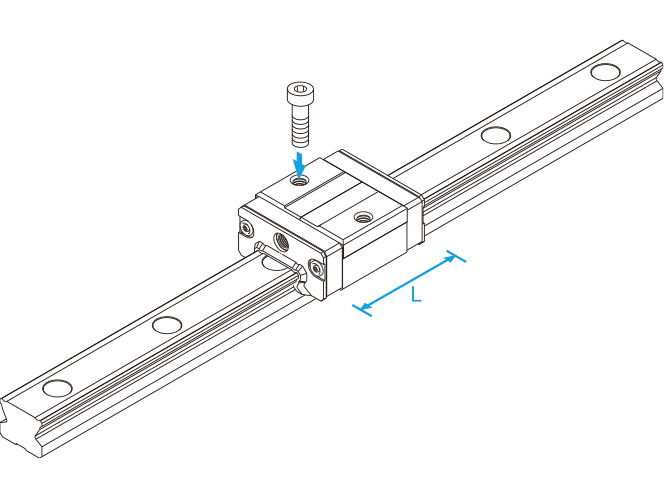

- Short block (LM Guide)

- Bolts mounted from above

Basic load rating(kN): Basic dynamic load rating 13.8 to 60.4 / Basic static load rating 20.5 to 81.8

Size :

15,20,25,30,35

- Bolts mounted from above

- Short block (LM Guide)

Basic load rating(kN) : Basic dynamic load rating 9.1 to 40.9 / Basic static load rating 11.7 to 46.7

Size :

15,20,25,30,35

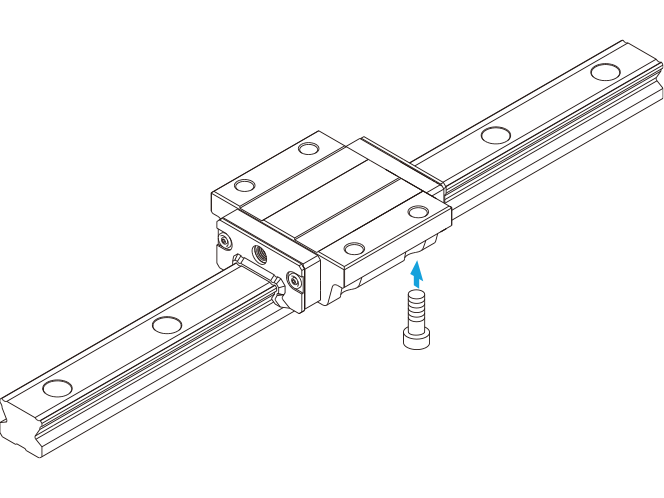

- Flange

- Bolts mounted from below

Basic load rating(kN) : Basic dynamic load rating 13.8 to 60.4 / Basic static load rating 20.5 to 81.8

Size :

15,20,25,30,35

- Flange

- Bolts mounted from below

- Short block (LM Guide)

Basic load rating(kN) : Basic dynamic load rating 9.1 to 40.9 / Basic static load rating 11.7 to 46.7

Size :

15,20,25,30,35

Features

Structure and Features

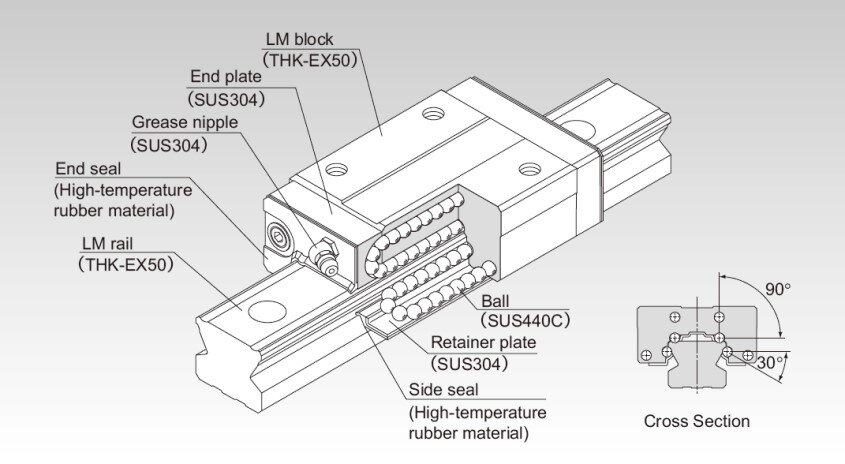

Balls roll in four rows of raceways precision-ground on an LM rail and an LM block, and endplates incorporated in the LM block allow the balls to circulate. Since it is a compactly designed model that has a low sectional height and a ball contact structure rigid in the radial direction, this model is optimal for horizontal guide units. High temperature type LM Guide model SR-M1 is capable of being used at service temperature up to 150°C thanks to THK’s unique technologies in material, heat treatment and lubrication.

Maximum Service Temperature: 150°C

Use of stainless steel in the endplates and high temperature rubber in the end seals achieves the maximum service temperature of 150°C.

Dimensional Stability

Since it is dimensionally stabilized, it demonstrates superb dimensional stability after being heated or cooled (note that it shows linear expansion at high temperature).

Highly Corrosion Resistant

Since the LM block, LM rail and balls use stainless steel, which is highly corrosion resistant, this model is optimal for clean room applications.

High Temperature Grease

This model uses high temperature grease that shows little grease-based fluctuation in rolling resistance even if temperature changes from low to high levels.

Thermal Characteristics of LM Rail and LM Block Materials

- Specific heat capacity: 0.481 J/(g・K)

- Thermal conductivity: 20.67 W/(m・K)

- Averagecoeffi cient of linear expansion: 11.8×10-6/°C

Service Life

When using this product in temperatures higher than 100°C, always multiply the basic dynamic load rating by the temperature coefficient when calculating the rated service life. SeeCalculating the Modified Nominal Lifefor details.

Detailed information for each model number

Dimensional drawing/Dimensional table

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |

Standard Lengths and Maximum Lengths of LM Rails

THK Online Services

Member-Exclusive Content

These contents can be accessed

after registering as a member.

Benefit 1: Useful features

-

Easy product comparisonsHighlight feature

Easy product comparisonsHighlight feature -

Save items for laterreview Favorites feature

Save items for laterreview Favorites feature

Benefit 2: Exclusive content

| Products | Contents |

|---|---|

| LM Guide | LM rail standard lengths and maximum length, tapped-hole type LM rail, frame for LM rail clamps, steel plate for LM rail clamps, etc. |

| Ball Screw | Axial clearance, maximum manufacturing length of shaft, etc. |

| Actuator | Movable part mass, etc. |