Installation

Installing the Cam Follower

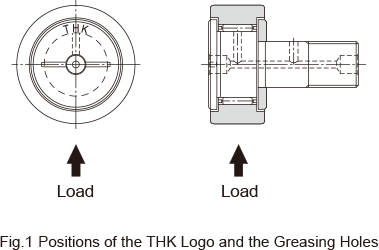

If the Cam Follower is to be used under a heavy load, it is necessary to install the product so that the greasing hole on the stud is out of the loaded area. To help identify the position of the greasing hole, the THK logo is marked on the side face of the stud collar. (See Fig.1 .)

The vertical hole in the middle of the stud is used as a whirl stop or a greasing hole.

Make sure that the outer ring is evenly in contact with the mating surface. When installing the Cam Follower, also make sure its axis is perpendicular to the traveling direction.

Installing the Eccentric Cam Follower

The eccentricity is adjusted in the following steps.

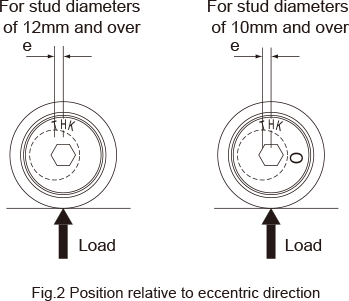

- Insert the stud into the mounting hole, and lightly tighten the nut until the nut starts turning. In doing so, position the THK logo in relation to the load direction as shown in Fig.2 .

- Use the hexagon socket on the stud head to turn the stud and adjust the clearance between the stud and the mating contact surface.

- After adjusting the clearance, tighten the nut while keeping the stud from turning. Be sure the maximum tightening torque in (see Table1 ) is not exceeded.

Using spring washers

If a spring washer is used to secure a cam follower, take care to check that the spring washer has no burrs or sharp edges. If there are burrs or sharp edges, contact between burrs or edges and the nut or flash washer used for mounting will cause abrasion and the abraded fragments will adhere to the stud screw. This will result in damage or incomplete tightening when the nut is tightened and may damage the screw section.

About the installation procedure

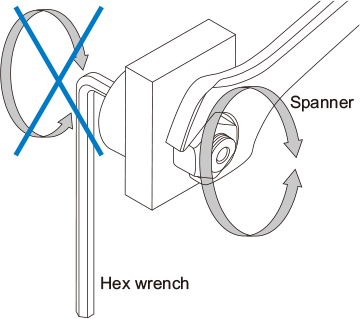

When mounting the Cam Follower, secure the flat-blade screwdriver groove and the hex wrench and turn the nut using a spanner. If turning the flat-blade screwdriver groove and the hex wrench side, the flat-blade screwdriver groove or the hexagon hole of the Cam Follower may be fractured.

Tightening Torque for the Stud

Since the stud of the Cam Follower receives bending stress and tensile stress caused by a bearing load, it is necessary to keep the tightening torque of the screw from exceeding the values indicated in Table1 .

If the mounting screw may be loosened due to vibrations or impact, use a spring washer, thin nuts of JIS B 1181 Class 3 as double-nuts or a special nut capable of preventing itself from loosening.

| Model No | Maximum tightening torqueN・m |

|---|---|

| CF, CFN, CFH, CFT, CFS and NUCF | |

| 2.5 | 0.18 |

| 3 | 0.392 |

| 4 | 0.98 |

| 5 | 1.96 |

| 6 | 2.94 |

| 8 | 7.84 |

| 10 10-1 | 16.7 |

| 12 12-1 | 29.4 |

| 16 | 70.6 |

| 18 | 98 |

| 20 20-1 | 137 |

| 24 24-1 | 245 * |

| 30 30-1 30-2 | 480 * |

Note) * is the value in case of the standard material (carbon steel). If a stainless steel type is to be used, the maximum value is 70% of this value.1 N・m equals to 0.102 kgf-m.