Contamination Protection and Lubrication

Cam Followers can be equipped with highly wear-resistant synthetic rubber seals to keep foreign matter out of the unit’s interior. A "UU" in the product code signifies a model equipped with seals. The Cam Follower comes with lithium soap-based grease No. 2, so it can be used without further greasing. Model CFN comes with urea-based grease No. 2. Prior to using the product, apply lubricant between the Cam Follower and the rolling contact surface as well. To replenish the Cam Follower with grease, fill grease into the greasing hole on the stud. However, note that some of the models with stud diameters of 10 mm or less do not have a greasing hole and are provided with initial lubrication only, and therefore do not allow replenishment of grease.

Please note that when replenishing lubricant from the grease nipple, the dedicated attachments (included with grease gun unit MG70) vary depending on the cam follower model number. (See Table2 )

| Model number |

Corresponding nipple model number |

Attachment Type |

|---|---|---|

| CF(H)-AB NUCF-AB |

— * | Type P |

| CF | NP3.2×3.5, PB1021B, NP6×5, NP8×9 |

Type N |

| CFH | ||

| CFN | ||

| CF-SFU | ||

| CFT | M6F, PT1/8 | Type H |

* CF(H)-AB and NUCF-AB models are pre-fitted with grease nipples.

Note) For the dimensions and shapes of the attachments, seeGrease Gun Unit MG70.

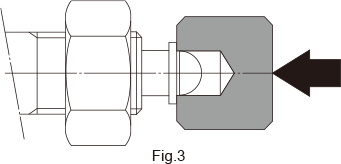

The appropriate fill quantity is a half to one third of the space inside the bearing. The lubrication interval varies depending on the operating conditions. As a guide, however, replenish grease of the same group every six months to two years for types with a cage, or every one to 6 months for fullroller types. Even with types equipped with seals ("...UU"), surplus grease may seep during the initial operation period or immediately after resumption of grease replenishment. If desiring to avoid contamination of the surrounding area of the machine by grease, first perform seasoning or the like in advance, and then wipe the seeping surplus grease. When driving the dedicated grease nipple onto the Cam Follower, use a jig like the one shown in Fig.3 to provide pressure to the flange of the nipple.