- Pick and Place

- System

Introduction

According to customers, most of them have a target cycle time set for a specific operation or a certain timeframe when selecting an actuator. We hear from many customers that would like to know how long it takes to pick and place workpieces with the PPR as well.

If you have specific operation patterns or workpiece conditions, please contact our sales staff or contact us through our inquiry form. We will be able to calculate and provide you with the theoretical feasibility of operation and cycle times that can be achieved. We would be happy to hear more about your requirements.

Here, we would like to introduce a sheet where we have calculated an approximation of how much operation can be accomplished with the PPR.

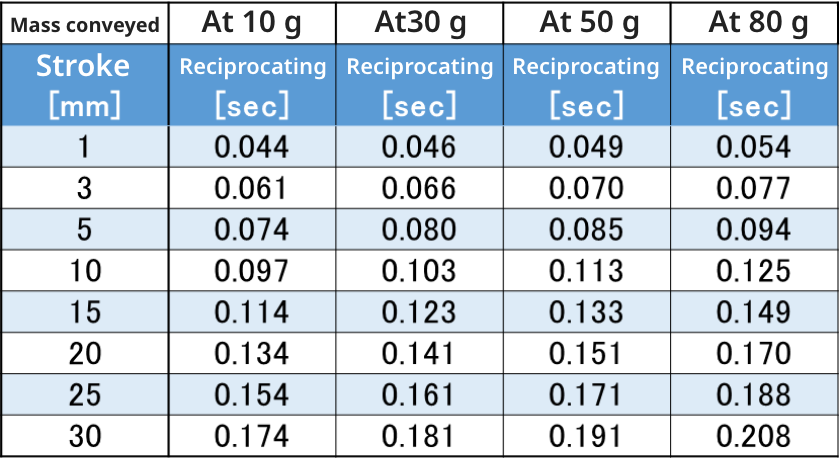

Reciprocating Motion Time with Position Control

First, we calculated the operation time for a simple reciprocating motion. The heavier the mass of the conveyed object, the greater the load on the motor. To move objects quickly and continuously convey obejcts, the motor needs to be set to operate within a range that will not damage it. The table shows the approximate time required for reciprocating motion of a given conveyed mass at a fixed stroke at the fastest possible speed and acceleration for operation based on the thrust of the linear motor on the Z axis.

For example, if the PPR is operated only by position control, the reciprocating motion time for the picking operation is: reciprocating motion time + suction time.

Approximate Z axis reciprocation time with the PPR-LR3

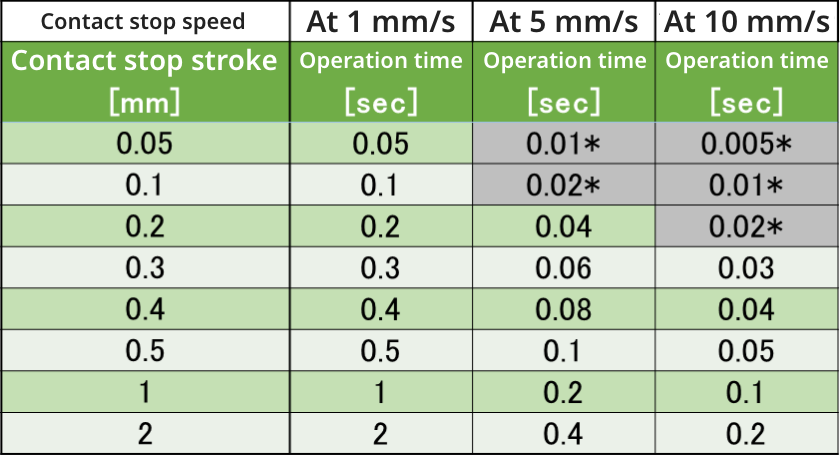

Operation Time When Using Contact Stop

Next, we have calculated the contact stop operation. When using the contact stop function, the PPR is able to stop the Z axis when the threshold value set by the force sensor is detected. Impact on the workpiece is minimized with this function. However, the impact on the workpiece varies by speed at the time of the contact stop. (In reality, the material of the nozzle, the base, and the workpiece itself, as well as the shape of the nozzle, may also have an effect on the impact on the workpiece.)

Here, we have described what the times would be for each stroke when the speed is set to the recommended 10 mm/s or less when using the PPR's contact stop.

For example, if a picking operation is performed using contact stop, the time is: operation time by position control described in the previous section + operation time by contact stop + suction time.

Approximate time for contact stop operation with PPR-LR3

- Contact stop operation requires a stroke of 20 to 30 ms.

Verification Using Actual Device

In consideration of the above, we have a video showing an experiment that tests how much operation is actually possible.

This is an example of high-speed pick and place with 5 mm stroke position control.

Here we have described the cycle times achievable with the PPR. In actual operations, the optimal program for you will be different depending on whether you need contact stop, how much you want to minimize impact force, and what the range of the stroke is before contacting something. If you contact us, we can consider your operation patterns to create a sample program according to the operation you wish to achieve. We hope this gives you an idea of what to expect when you are ready to adopt our products.