Service Life (SKR)

LM Guide Unit

Nominal Life

The nominal life means the total travel distance that 90% of a group of units of the same LM Guide model can achieve without flaking (scale-like pieces on the metal surface) after individually running under the same conditions.The nominal life of the LM Guide is obtained using the following formula.

Calculating the Nominal Life

The nominal life (L10) of an LM Guide with balls is obtained from the following formula using the basic dynamic load rating (C), which is based on a reference distance of 50 km, and the calculated load acting on the LM Guide (PC ).

- LM Guide with balls (Using a basic dynamic load rating based on a nominal life of 50 km)

L10 Nominal life (km) C Basic dynamic load rating (N) Pc Calculated load (N) *This nominal life formula may not apply if the length of the stroke is less than or equal to twice the length of the LM block.

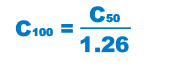

When comparing the nominal life (L10), you must take into account whether the basic dynamic load rating was defined based on 50 km or 100 km. Convert the basic dynamic load rating based on ISO14728-1 as necessary.

ISO-regulated basic dynamic load rating conversion formula:

- LM Guide with balls

C50 Basic dynamic load rating based on a nominal life of 50 km C100 Basic dynamic load rating based on a nominal life of 100 km

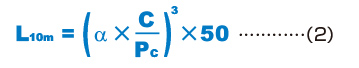

Calculating the Modified Nominal Life

During use, an LM Guide may be subjected to vibrations and shocks as well as fluctuating loads, which are difficult to detect. In addition, having LM blocks arranged directly behind one another will have a decisive impact on the service life. Taking these factors into account, the modified nominal life (L10m) can be calculated according to the following formula (2).

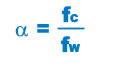

- Modified factor α

α Modified factor fc Contact factor (see Table9 ) fw Load factor (see Table8 ) - Modified nominal life L10m

- LM Guide with balls

L10m Modified nominal life (km) C Basic dynamic load rating (N) Pc Calculated load (N)

- LM Guide with balls

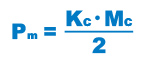

- If a moment is applied, calculate the equivalent load by multiplying the applied moment by the equivalent factor indicated in Table10.

Pm Equivalent load (per inner block) (N) K Equivalent moment factor M Applied moment (N・mm) (If planning to use the product with a wide inner block span, contact THK.)If moment Mc is applied to model SKR-B/D

- If a radial load (P) and a moment are simultaneously applied to model SKR

PE Overall equivalent radial load (N)

Perform a nominal life calculation using the above data.

Service Life Time

When the nominal life (L10) has been obtained, the service life time is obtained using the following equation (if the stroke length and the number of reciprocations per minute are constant).

| Lh | Service life time (h) |

|---|---|

| ℓs | Stroke length (mm) |

| n1 | Number of reciprocations per minute (min‒1) |

Ball Screw Unit/Bearing Unit(Fixed Side)

Nominal Life

The nominal life (L10) means the total travel distance that 90% of a group of units of the same ball screw (bearing) can achieve without flaking after individually running under the same conditions.The nominal life of the ball screw unit/bearing unit (fixed side) is obtained using the following equation.

Calculating the Nominal Life

The nominal life (L10) is obtained from the following equation using the basic dynamic load rating (Ca) and the load acting on the ball screw in the axial direction (Fa ).

| L10 | Nominal life (rev.) |

|---|---|

| Ca | Basic dynamic load rating (N) |

| Fa | Axial load (N) |

Calculating the Modified Nominal Life

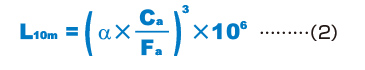

During use, a ball screw may be subjected to vibrations and shocks as well as fluctuating loads, which are difficult to detect. Taking these factors into account, the modified nominal life (L10m) can be calculated according to the following formula (2).

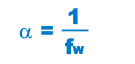

- Modified factor α

α Modified nominal life fw Load factor (see Table8 ) - Modified nominal life L10m

L10m Modified nominal life (rev.) α Modified nominal life Ca Basic dynamic load rating (N) Fa Axial load (N) Table8 Load Factor (fw)Vibrations/impact Speed(V) fw Faint Very low

V≦0.25m/s1 to 1.2 Weak Slow

0.25m/s<V≦1m/s1.2 to 1.5 Medium Medium

1m/s<V≦2m/s1.5 to 2 Strong High

V>2m/s2 to 3.5

Service Life Time

When the nominal life (L10) has been obtained, the service life time is obtained using the following equation (if the stroke length and the number of reciprocations per minute are constant).

| Lh | Service life time (h) |

|---|---|

| ℓs | Stroke length (mm) |

| n1 | Number of reciprocations per minute (min‒1 ) |

| ℓ | Ball screw lead (mm) |

fc : Contact Factor

If two inner blocks are used in close contact with each other with model SKR-B/D, multiply the basic load rating by the corresponding contact factor indicated in Table9 .

| Block type | Contact factor fc |

|---|---|

| Model SKR-B Model SKR-D |

0.81 |

fw : Load Factor

In general, machines in reciprocal motion are likely to cause vibration and impact during operation, and it is particularly difficult to accurately determine each of vibration generated during high-speed operation, impact applied during repeated starting and stopping in normal use, etc. Therefore, where the effect of speed vibration is estimated to be significant, divide the basic load rating (C) by an empirically obtained load factor.

K: Moment Equivalent Factor (LM Guide Unit)

When model SKR travels under a moment, the distribution of load applied to the LM Guide is locally large. In such cases, calculate the load by multiplying the moment value by the corresponding moment equivalent factor indicated inTable10 . Symbols KA, KB and KC indicate the moment equivalent loads in the MA, MB and MC directions, respectively.

| Model No. | KA | KB | KC |

|---|---|---|---|

| SKR20-A | 2.34×10‒1 | 2.34×10‒1 | 8.07×10‒2 |

| SKR20-B | 4.38×10‒2 | 4.38×10‒2 | 8.07×10‒2 |

| SKR26-A | 1.59×10‒1 | 1.59×10‒1 | 6.17×10‒2 |

| SKR26-B | 3.18×10‒2 | 3.18×10‒2 | 6.17×10‒2 |

| SKR33-A | 1.42×10‒1 | 1.42×10‒1 | 5.05×10‒2 |

| SKR33-B | 2.47×10‒2 | 2.47×10‒2 | 5.05×10‒2 |

| SKR33-C | 2.39×10‒1 | 2.39×10‒1 | 5.05×10‒2 |

| SKR33-D | 3.54×10‒2 | 3.54×10‒2 | 5.05×10‒2 |

| SKR46-A | 9.51×10‒2 | 9.51×10‒2 | 3.46×10‒2 |

| SKR46-B | 1.70×10‒2 | 1.70×10‒2 | 3.46×10‒2 |

| SKR46-C | 1.46×10‒1 | 1.46×10‒1 | 3.46×10‒2 |

| SKR46-D | 2.36×10‒2 | 2.36×10‒2 | 3.46×10‒2 |

| SKR55-A | 8.12×10‒2 | 8.12×10‒2 | 2.88×10‒2 |

| SKR55-B | 1.46×10‒2 | 1.46×10‒2 | 2.88×10‒2 |

| SKR65-A | 7.16×10‒2 | 7.16×10‒2 | 2.21×10‒2 |

| SKR65-B | 1.27×10‒2 | 1.27×10‒2 | 2.21×10‒2 |

KA: Moment equivalent factor in the MA direction.

KB: Moment equivalent factor in the MB direction.

KC: Moment equivalent factor in the KC direction.

- Note) The values for models SKR-B/D indicate the values when double inner blocks are used in close contact with each other.