Sep 24, 2025

Products

High Performance in a Compact, Lightweight Package: The Latest in Ball Spline Technology

- Example of Use

- Column

- New Product

- General Industrial Machinery

- Industrial Robots

- Precision Machinery / Instrument

- Electricity / Electronics

- Semiconductor Manufacturing Equipment

- Automotive and Transportation Equipment

- Picking Robot

- Articulated Robot

- THK Online Services

- High Rigidity

- Pick&Place

- Labor Savings

- High Accuracy

- High Speed

- Ball Spline

We’ve featured ball splines twice before in this Product Journal. The first time, we covered the basics of the different types of linear motion guides and explained the benefits of using ball splines in terms of sustained accuracy, improved durability, and reduced cost. In our second ball spline article, we looked at how customization allows us to create the perfect ball spline for enhancing the performance of our customers’ equipment and even offered a few real-world examples. This time, we're going to highlight our latest ball splines, which are more compact and lightweight than ever before.

Article 2: Standard Parts Aren't Always the Answer! Customizing Ball Splines for Maximum Performance

Why Make Things Compact and Lightweight?

Recent spikes in labor and material costs are driving manufacturers to pursue ever greater productivity. At the same time, many companies have limited space for their equipment and have to make the most of the space they do have on the production floor. This makes compact equipment design essential. More compact equipment not only saves space, it also results in lighter machine cores that are less demanding on motors and more capable of high-speed motion that helps boost productivity. It can drive down material and shipping costs at the same time as it drives up productivity per unit area. Recently, many companies have set goals related to the SDGs that require greater energy efficiency and equipment designed with the environment in mind. When reviews of conventional equipment lead to the creation of lighter machine cores, the result is equipment that consumes less electricity overall. All of these factors make compact machine core design a crucial factor in both driving productivity and taking care of the environment.

The Latest Compact Ball Splines

To answer the call for more compact, lightweight components, THK released its compact ball spline models, the LT-X, LF-X, and LTR-V, each packed with an assortment of the latest ball spline technologies. Let's take a look at the features these products offer and some of the latest technology at work inside them.

1. Compact and lightweight

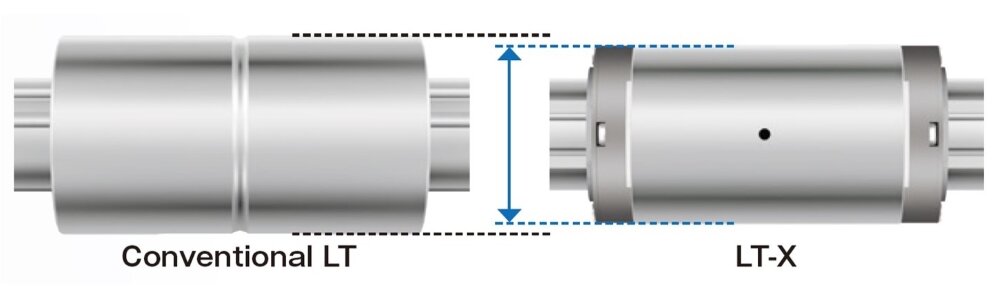

Thanks to a revised ball circulation path, these compact ball splines have a smaller outer diameter than conventional models, making them up to 20% more compact. This allows for more compact machine core design.

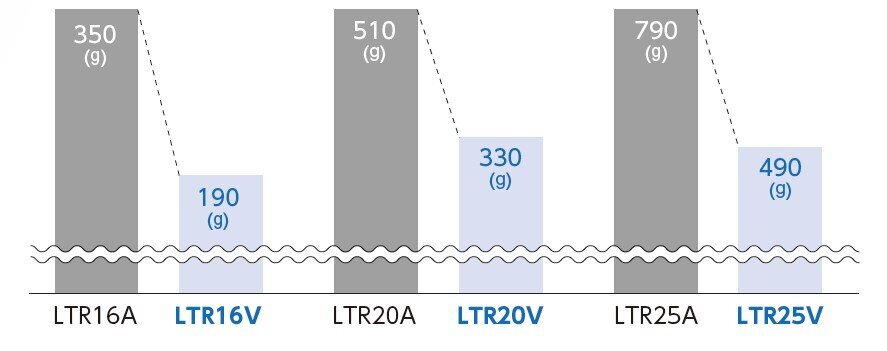

The Rotary Ball Spline Model LTR-V with its integrated support bearing is also up to 46% lighter than its predecessors, owing to the Model LT-X used for its ball spline component. This gives it a lower moment of inertia as a result, meaning it can rapidly start and stop in a way that contributes to high-speed motion and faster cycle times.

2. Smooth, high-speed motion

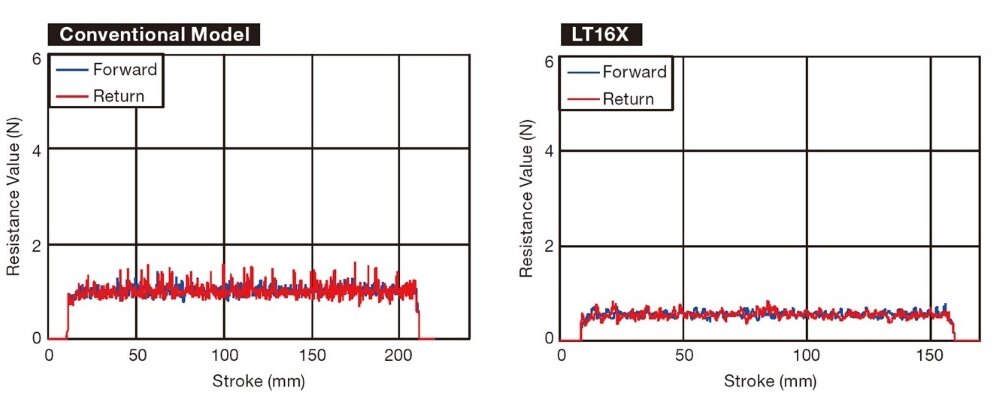

These ball splines use a redesigned ball circulation path that optimizes ball circulation to provide high-speed motion. Testing was performed under the following conditions to verify that they could be run 10,000 km without experiencing any abnormalities. These new ball splines also provide smoother motion with less variation in sliding resistance than previous models.

High-Speed Durability Test Conditions

|

Item |

Description |

|---|---|

|

Model used |

LT20X |

|

Speed |

2 m/s |

|

Acceleration/deceleration |

40 m/s2 |

|

Lubricant |

Lithium soap-based grease (AFB-LF Grease) |

|

Stroke |

650 mm |

|

Orientation |

Horizontal |

Sliding Resistance Test Conditions

|

Item |

Description |

|---|---|

|

Speed |

10 mm/s |

|

Lubricant |

Lithium soap-based grease (AFB-LF Grease) |

|

Orientation |

Horizontal |

3. An extensive product lineup

In addition to the Model LT-X, the Model LF-X, and the Rotary Ball Spline Model LTR-V mentioned above, our compact ball spline series also includes the Model LFK-X and the Model LFH-X, which provide customers with even more compact options.

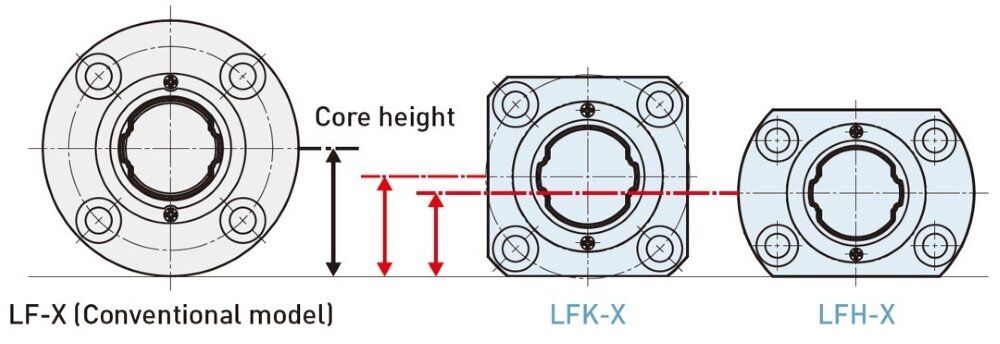

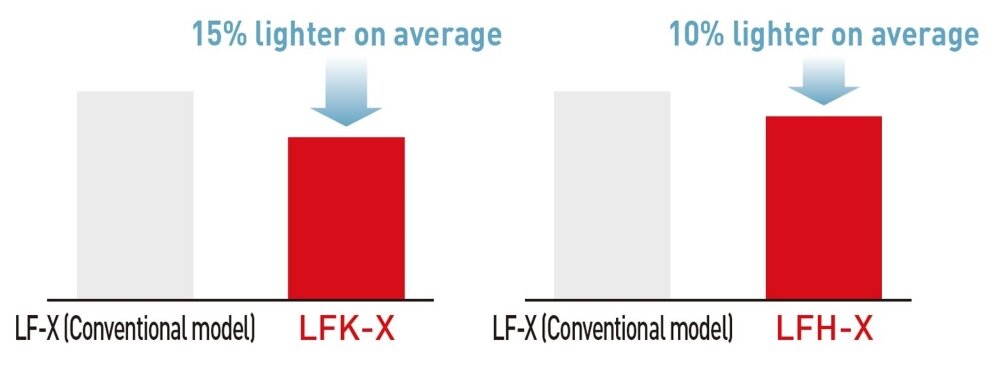

Models LFK-X and LFH-X have lower core heights than the Model LF-X, which allows for more compact mounting and peripheral components. The square flange of the Model LFK-X and the cut flange of the Model LFH-X also make them even lighter than the Model LF-X with its round flange. This ultimately helps make equipment lighter overall.

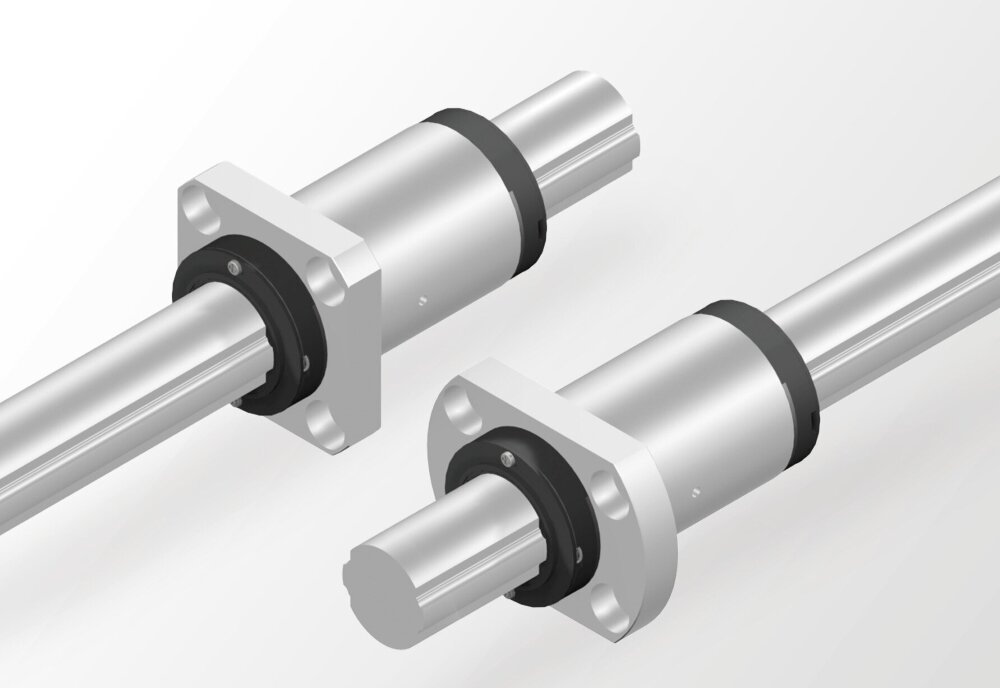

4. Significantly extended maintenance intervals

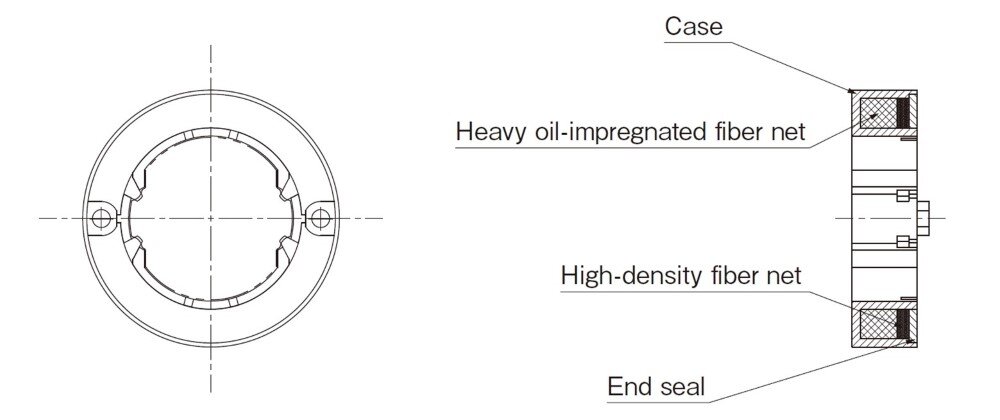

These ball splines are also compatible with the optional QZ Lubricator. The QZ Lubricator is a lubrication unit that can be attached to both ends of a ball spline to deliver an appropriate amount of lubricant to the ball spline shaft's raceway groove from its internal supply. It replaces exhausted lubricant so that an oil film can constantly be formed between the balls and the raceway, which significantly extends the lubrication maintenance interval.

Because it only feeds an appropriate amount of lubricant to the raceway groove, it also serves as an eco-conscious lubrication system that doesn't contaminate the surrounding area.

Case Studies: More Compact, Lightweight Creations

Let’s look at a few examples of places where compact ball splines are being used.

Case study 1: A robot manufacturer that had been thinking about how to make their industrial robots lighter chose to use the compact ball spline Model LF-X for an arm slide mechanism and found that it provided a 20% reduction in weight. The lighter design generated less inertia, so it was capable of higher speeds and more rapid acceleration and deceleration. It also succeeded at reducing energy consumption by being less demanding on the drive motor.

Case study 2: When the compact ball spline Model LT-X was used to provide the kind of precise positioning required by semiconductor manufacturing equipment, it allowed the machines to be made smaller, faster, and more integrated in structure and contributed to more accurate component mounting. The optional QZ Lubricators attached to these ball splines allowed them to go significantly longer before they needed lubrication. Such highly accurate, lightweight positioning systems ultimately help boost equipment accuracy overall.

These compact ball splines are used to make space-saving transfer equipment that offers smooth linear transport and in a variety of other applications as well.

Pushing for Greater Productivity!

This time, we looked at THK’s lineup of compact, lightweight ball splines. Please don’t hesitate to contact THK with any concerns you have about making equipment more compact and lightweight. We offer various options that can meet your needs, including custom products.

Details about the Model LF-X/LF-XL (THK website)

Details about the Model LFK-X (THK website)

Details about the Model LFH-X (THK website)

*This content is based on information that was released in Japanese on September 24, 2025.