Nov 28, 2023

products

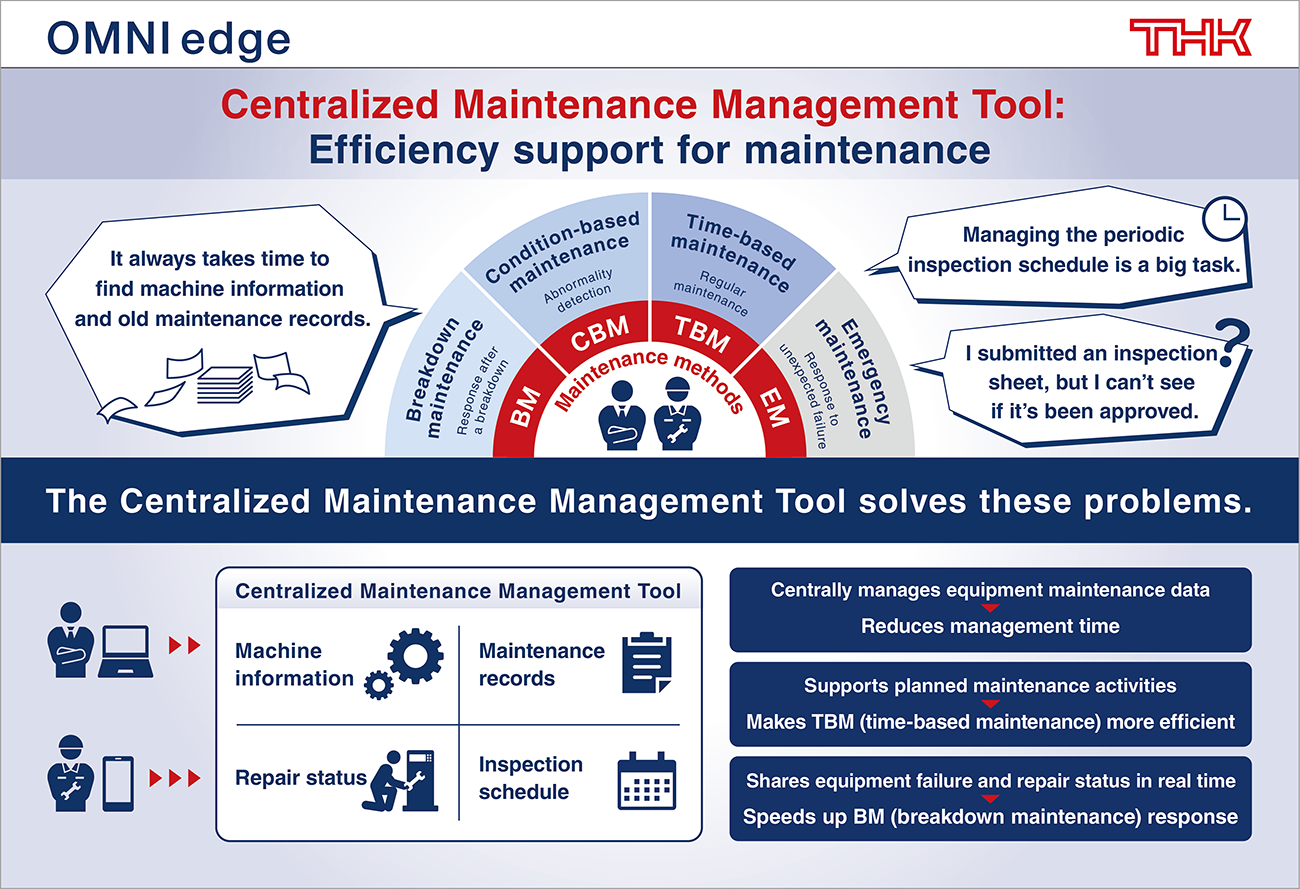

OMNIedge Centralized Maintenance Management Tool Now Available: Digitizing Equipment Maintenance Information to Maximize Efficiency

THK CO., LTD. (Location: Minato, Tokyo; CEO: Akihiro Teramachi; hereinafter referred to as “THK”) is now offering the Centralized Maintenance Management Tool through its “OMNIedge” OEE (overall equipment effectiveness) optimization system.

As manufacturing facilities deal with labor shortages and aging equipment, demand has risen for DX (digital transformation) solutions for maintenance and ways to make the PDCA cycle more efficient. Until now, THK has released a variety of solutions that enable CBM (condition-based maintenance), such as its predictive failure detection AI solution for linear components (the LM Guide, ball screws, and actuators) and rotary components (motors, pumps, and fans) in addition to the Tool Monitoring AI Solution for cutting tools used in machine tools.

Meanwhile, companies are looking for ways to manage a balance of different maintenance methods, including TBM (time-based maintenance) and BM (breakdown maintenance) alongside CBM. By releasing the Centralized Maintenance Management Tool, THK now provides comprehensive support for maintenance management and operations. This tool enables users to centralize management of equipment and maintenance data (maintenance records, repair status, periodic maintenance notifications, workflows, etc.) on the cloud to make the maintenance PDCA cycle more efficient. For instance, sharing information about equipment trouble and the progress of repairs with the relevant parties in a timely manner will enable quick responses to even sudden equipment failure. In addition, this tool supports planned maintenance and helps make sure nothing gets missed by automatically sending out reminders to the relevant parties when the calendar is used to centralize management of the daily inspection schedule.

Utilizing the Centralized Maintenance Management Tool that supports TBM and BM in conjunction with previous CBM solutions will enable users to achieve the optimal balance of TBM, BM, and CBM activities for their equipment. This will boost users’ maintenance efficiency and make sure their production lines never stop running.

Features of the Centralized Maintenance Management Tool

Centrally manages equipment maintenance data (TBM, BM, CBM, etc.)

This tool connects and centrally manages equipment and maintenance information on the cloud. Users can instantly access everything from past maintenance records to the latest status, which drastically reduces the time it takes to manage data.

Helps schedule planned maintenance

The daily inspection schedule is centrally managed on a calendar. Using the automatic notification feature will ensure that personnel never forget to perform an inspection.

Shares timely updates with relevant parties

The tool gives the relevant parties timely updates on the status of broken machines and repair efforts. The Centralized Maintenance Management Tool handles everything from repair reports to supervisor approvals, which boosts the efficiency of operations.

OEE Optimization System OMNIedge

OMNIedge is an IoT solution service that reduces loss that occurs on the manufacturing floor and contributes to maximizing overall equipment effectiveness (OEE). This service combines the sensor and other hardware, a communication device, and the AI solution as a set package, making the service simple, secure, and available for a reasonable price.

Lineup

Phase 1: Predictive failure detection AI solution for linear motion components (available now)

Phase 2: Predictive failure detection AI solution for rotary components (available now)

Phase 3: Tool monitoring AI solution (available now)

OMNIedge Website

https://www.thk.com/omniedge/en/

Related News

March 1, 2023 Orders Officially Open for "OMNIedge" IoT Service for Manufacturing's AI Diagnosis Service (ADV) for Rotary Components, in Which AI Predicts Rotary Component Abnormalities and Failures and Specifies Recommended Maintenance

November 22, 2022 "OMNIedge” Now Provides a Tool Monitoring AI Solution that Detects Cutting Tool Damage and Wear to Reduce Loss

June 15, 2022 OMNIedge, an IoT Service for Manufacturing, Now Supports Private Cloud

February 2, 2022 OMNIedge, an IoT Service for Manufacturing, Now Provides Predictive Failure Detection for Rotary Components

November 9, 2021 Global SIM Compatibility for the “OMNIedge” IoT Service for Manufacturing Now Available in Taiwan and Singapore

July 19, 2021 Two Bonus Features Now Available to Add Peace of Mind to the “OMNIedge” IoT Service for Manufacturing

June 30, 2021 OMNIedge, an IoT Service for Manufacturing, Officially Launches in China

March 10, 2021 The “OMNIedge” IoT Service Now Available for Actuators

February 17, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry Now Connects with FIELD system: Bolstering the Service with Industrial

February 3, 2021 The “OMNIedge” IoT Service for the Manufacturing Industry Goes Global: A New Service Compatible with Global SIM

November 16, 2020 The “OMNIedge” IoT Service for the Manufacturing Industry: Service Now Available for Ball Screws

Note) This information was originally released in Japanese on November 28, 2023.

Contact information

Please direct any media inquiries to:

Toru Nakagawa & Akio Ishikawa, Marketing & Public Relations Unit, THK CO., LTD.

Phone: +81-3-5730-3845

E-mail: thk-sp@thk.co.jp