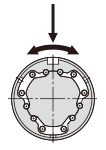

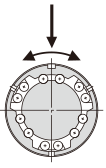

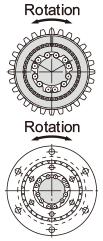

| High torque Caged Ball type |

|

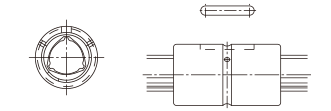

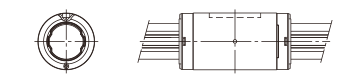

Type SLS

Type SLS-L |

|

Nominal shaft

diameter

25 to 100 mm |

Details |

- Redesigning the shape of the conventional high torque type spline shaft to be morecircular significantly improves its torsion and flexural rigidity.

- Models SLS/SLF adopt the caged-ball technology to enable the circulating motion of evenly spaced balls to be maintained and high-speed response to be achieved, the cycle time of the machine can be improved.

- Models SLS/SLF adopt the caged-ball technology, they eliminate collision and mutual friction between balls, and realize low noise,pleasant running sound and low particle generation.

- Models SLS/SLF adopt the caged-ball technology to substantially increase the grease retention, thus achieving long-term maintenance-free operation.

- Models SLS/SLF adopt the caged-ball technology and a new circulation method, thus achieving stable and smooth motion withsmall rolling fluctuation.

|

- Column and arm of industrial robot

- Automatic loader

- Transfer machine

- Automatic conveyance system

- Tire molding machine

- Spindle of spot-welding machine

- Guide shaft of high-speed automatic coating machine

- Riveting machine

- Wire winder

- Work head of electric discharge machine

- Spindle drive shaft of grinding machine

- Speed gears

- Precision indexing machine

|

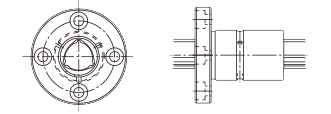

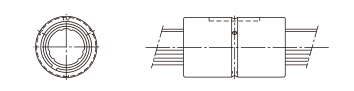

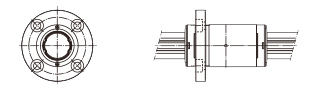

| Type SLF |

|

Nominal shaft

diameter

25 to 100 mm |

Details |

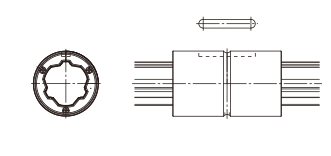

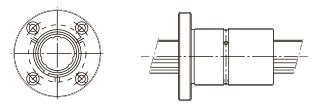

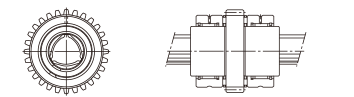

| High torque type |

|

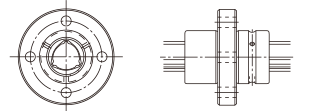

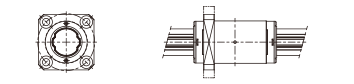

Type LBS

Type LBST |

|

Nominal shaft

diameter

15 to 150 mm |

Details

Details |

- The spline shaft has three crests equidistantly formed at angles of 120°. On both sides of each crest, two rows (six rows intotal) of balls are arranged to hold the crest from both sides. The angular-contact design of the ball contact areas allows an appropriate preload to be evenly applied.

- Since the balls circulate inside the spline nut, the outer dimensions of the spline nut are compactly designed.

- Even under a large preload, smooth straight motion is achieved.

- Since the contact angle is large (45°) and the displacement is minimal, high rigidity is achieved.

- No angular backlash occurs.

- Capable of transmitting a large torque.

|

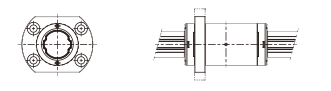

| Type LBF |

|

Nominal shaft

diameter

15 to 100 mm |

Details |

| Type LBR |

|

Nominal shaft

diameter

15 to 100 mm |

Details |

| Type LBH |

|

Nominal shaft

diameter

15 to 50 mm |

Details |

| Medium torque type |

|

Type LT |

|

Nominal shaft

diameter

4 to 100 mm |

Details |

- The spline shaft has two to three crests. On both sides of each crest, two rows (four tosix rows in total) of balls are arranged to hold the crest from both sides. This design allowsan appropriate preload to be evenly applied.

- The contact angle of 20° and an appropriate preload level eliminate angular backlash, providing high-torque moment rigidity.

|

- Die-set shaft and similar applications requiring straight motion under a heavy load

- Loading system and similar applications requiring rotation to a given angle at a fixed position

- Automatic gas-welding machine spindle and similar applications requiring a whirl-stop on one shaft

|

- Column and arm of industrial robot

- Spot-welding machine

- Riveting machine

- Book-binding machine

- Automatic filler

- XY recorders

- Automatic spinner

- Optical measuring instrument

|

| Type LF |

|

Nominal shaft

diameter

6 to 50 mm |

Details |

|

|

Type LT-X |

|

Nominal shaft

diameter

4 to 30 mm |

Details |

- The length and external diameter of the LT-X ball spline’s outer cylinder are the same as those of an LM-series linear bushing, meaning the nut can be replaced with a linear bushing.

|

| Type LF-X |

|

Nominal shaft

diameter

4 to 30 mm |

Details |

- The length and external diameter of the LF-X ball spline’s nut are the same as those of theModel LMF linear bushing, meaning the nut can be replaced with a linear bushing.

|

| Type LFK-X |

|

Nominal shaft

diameter

5 to 30 mm |

Details |

- The Model LFK-X is a lightweight and compact product designed with a lower core height than the Model LF-X.

|

| Type LFH-X |

|

Nominal shaft

diameter

5 to 30 mm |

Details |

- The Model LFH-X is a lightweight and compact product designed with a lower core height than the Model LFK-X.

|

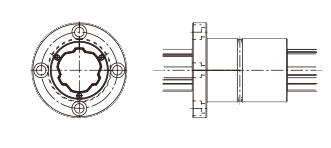

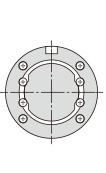

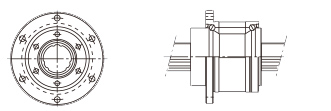

| Rotary type |

|

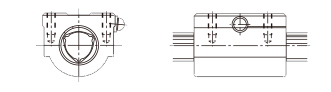

Type LBG

Type LBGT |

|

Nominal shaft

diameter

20 to 85 mm |

Details |

- A unit type that has the same contact structure as model LBS. The flange circumference on the spline nut is machined to have gear teeth, and radial and thrust needle bearings are compactly combined on the circumference of the spline nut.

|

- Speed gears for high torque transmission

|

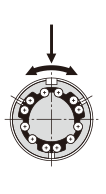

Type LTR-A

Type LTR |

|

Nominal shaft

diameter

8 to 60 mm |

Details

Details |

- A lightweight and compact type based on model LT, but has a spline nut circumference machined to have angular-contact type ball raceways to accommodate support bearings.

|

- Z axis of scalar robot

- Wire winder

|