Built-in force sensor facilitates easy quality stabilization

The World's First* Process-Optimizing Robot

Linear rotary actuators with high precision force control

Pick and

Place

Robot

- First in the world as a process-optimizing robot specialized for pick and place processes with an integrated force sensor, motor, pneumatic device, and control circuit board.

All in One P&P System

Equipment becomes too large to maintain cycle time due to many devices being mounted.

Thin, lightweight all-in-one design

Achieves high-speed pick and place with easy installation and minimal wiring

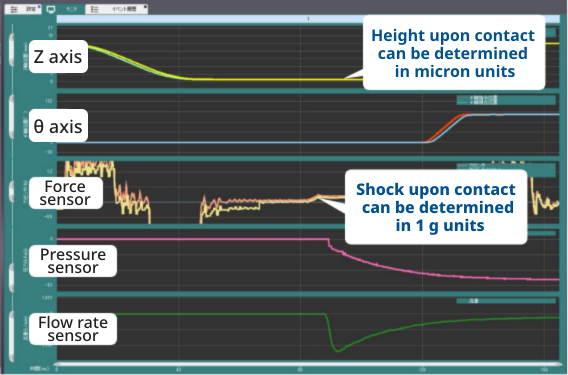

Control and Visualization of Position and Force

Protects minute workpieces from damage

Pick and Place Robot

The PPR not only supports linear and rotary operation, but also has pneumatic devices and various sensors integrated.

The all-in-one robot combines all components required for optimized pick and place applications.

- See more details on

Integrated pneumatic unit model - See more details on

position control-only models

| Features | PPR2-LR04 (Small head model) |

PPR-LR3 (Integrated pneumatic unit model) |

PPR-LR3-LF1 (position control only model) |

|---|---|---|---|

| High-speed pick and place | |||

| High-precision positioning | |||

| Contact stop | |||

| Force control | |||

| Waveform monitor | ※ | ||

| Space-saving |

* Monitoring of force waveforms is not available.

Please feel free to

contact us regarding

technical consultation

and price/delivery.

Installation Support

Support staff who have mastered the use of the PPR will verify the implementation from many angles to ensure that there are no issues.

When considering a purchase of a product, we will interview you about your needs, starting from concepts such as "something like this" and "I want to run it like this." Please feel free to contact us.

Technical calculation

(cycle time/

transportability)

We can pre-calculate the feasibility of operation based on the mass and inertia of the conveyed object and its operation pattern.

Experiment

(workpiece pick and place trial)

We will experiment using actual workpieces, nozzles, etc. to determine whether or not the envisioned operation can be performed.

Demo machine rental

When considering a purchase, we will be happy to lend you a demo unit. Please contact us with the details you wish to confirm.

Sample program

We can provide a sample operation program that matches the actual usage concept. Please consult us about connecting to PLC.

Case Studies

Technical Information

FAQ

Is stacked installation possible?

Stacked installation is possible.

The mounting pitch is 16 mm.

*For details, please refer to the instruction manual 4-2-4 How to install the head.

Are the screw holes for mounting the body on the side only?

Screw holes for mounting are located on both sides and on the underside.

Side: M4 depth 4 screw holes x 2, φ4H7 depth 4 pin holes x 1, 4H7 depth 4 long holes

Lower holes: M3 depth 3 threaded holes x 2

*Please be careful about the length of the mounting screws to prevent damage to internal components.

*Please refer to the instruction manual 4-2-4 How to install the head.

A timeout has occurred. I would like to investigate the cause.

Confirm the waveform monitor and event history screens.

When a timeout occurs, which module is the last module in operation?

If that step operates and a timeout occurs, it is very likely that it will stop at the next step.

If you send us the waveform data, we will be able to assist you in your investigation.