Selecting a Nut

Types of Nuts

The nuts of the Ball Screws are categorized by the ball circulation method into the return-pipe type,the deflector type and end the cap type. These three nut types are described as follows.

In addition to the circulation methods, the Ball Screws are categorized also by the preloading method.

Types by Ball Circulation Method

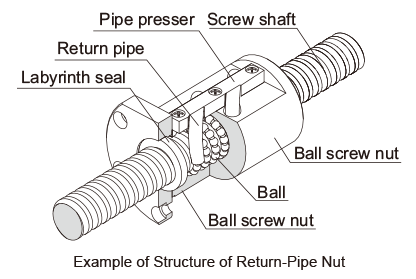

Return-Pipe Type(Models SBN-V (Medium), BIF-V(Medium), BIF, BNF-V (Medium), BNF,BNFN-V (Medium), BNFN, BNT, BTK-V), Return-Piece Type(Models SBN-V (Small), HBN, BIF-V(Small), BNF-V (Small), BNFN-V (Small)

These are the most common types of nuts, which use a return pipe for ball circulation. The return pipe allows balls to be picked up, pass through the pipe and return piece, and return to their original positions to circulate endlessly.

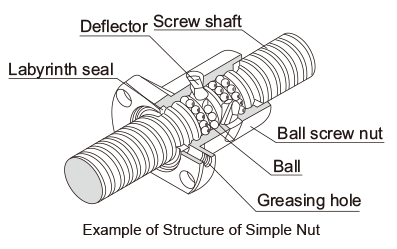

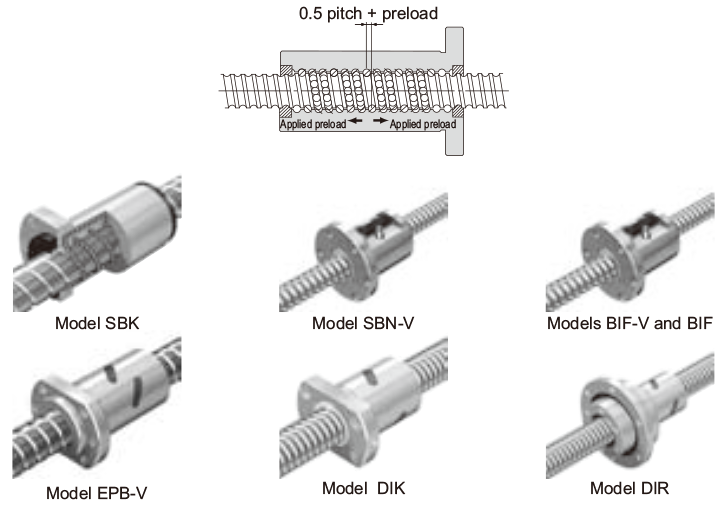

Deflector Type(Models EBB-V, EPB-V, DK, DKN, DIK,JPF, DIR and MDK)

These are the most compact type of nut. Theballs change their traveling direction with adeflector, pass over the circumference of thescrew shaft, and return to their original positionsto complete an infinite motion.

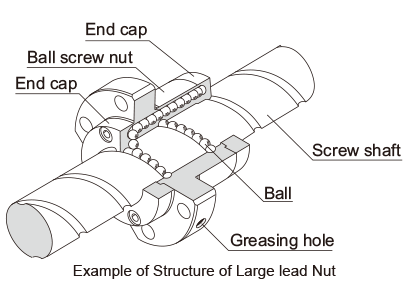

End-cap Type: Large lead Nut(Models SBK, SBKN, SBKH, WHF, BLK, WGF,BLW, WTF, CNF and BLR)

These nuts are most suitable for the fast feed.The balls are picked up with an end cap, pass through the through hole of the nut, and return to their original positions to complete an infinite motion.

Types by Preloading Method

Fixed-point Preloading

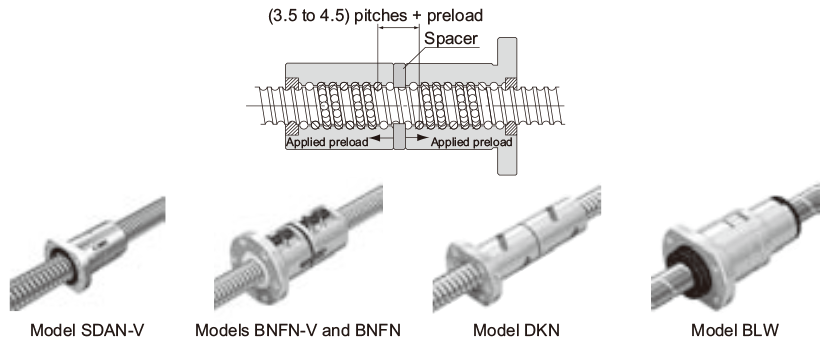

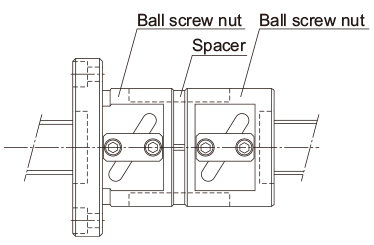

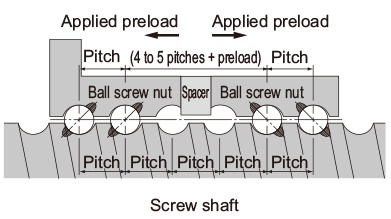

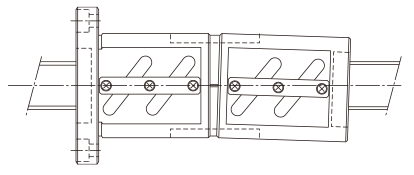

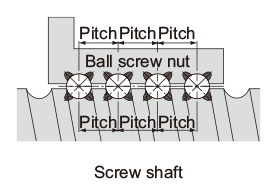

Double-nut Preload (Models SBKN, SDAN-V, BNFN-V, BNFN, DKN and BLW)

A spacer is inserted between two nuts to provide a preload.

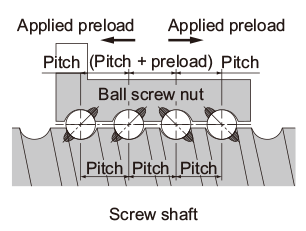

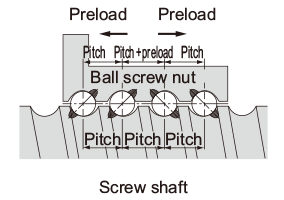

Off set Preload (Models SBK, SBN-V, BIF-V, BIF, EPB-V, DIK and DIR)

More compact than the double-nut method, the off set preloading provides a preload by changing the groove pitch of the nut without using a spacer.

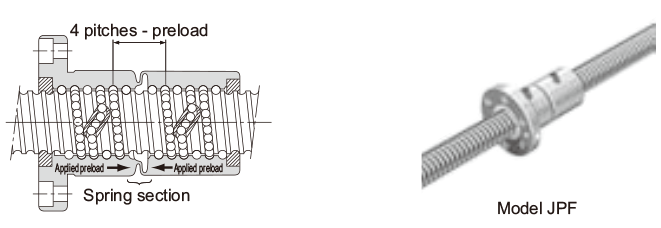

Constant Pressure Preloading (Model JPF)

With this method, a spring structure is installed almost in the middle of the nut, and it provides a preload by changing the groove pitch in the middle of the nut.

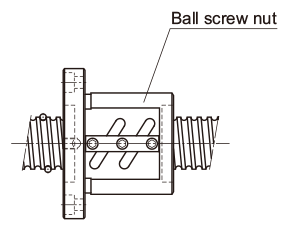

Structure and Features of Off set Preload Type Simple-Nut Ball Screw

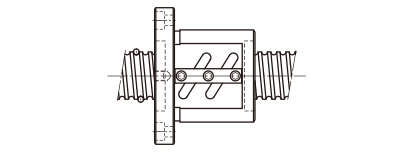

The Simple-Nut Ball Screw is an off set preload type in which a phase is provided in the middle of a single ball screw nut, and an axial clearance is set at a below-zero value (under a preload).

The Simple-Nut Ball Screw has a more compact structure and allows smoother motion than the conventional double-nut type (spacer inserted between two nuts).

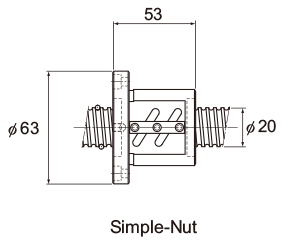

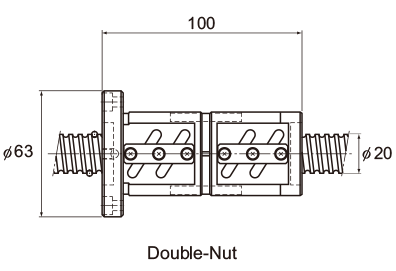

Comparison between the Simple Nut and the Double-Nuts

| Simple-Nut Ball Screw | Conventional Double-Nut Type Ball Screw |

|---|---|

|

|

| Preloading Structure | |

|

|

| Rotational Performance | |

|

The preload adjustment with Simple Nut Ball Screw is performed according to the ball diameter.This eliminates the inconsistency in the contact angle, which is the most important factor of the Ball Screw performance. It also ensures the high rigidity, the smooth motion and the high wobbling accuracy.  |

The use of a spacer in the double-nuts tends to cause inconsistency in the contact angle due to inaccurate flatness of the spacer surface and an inaccurate perpendicularity of the nut. This results in a non-uniform ball contact, an inferior rotational performance and a low wobbling accuracy.  |

| Dimensions | |

|

Since Simple-Nut Ball Screw is based on apreloading mechanism that does not require a spacer, the overall nut length can be kept short. As a result, the whole nut can be lightly and compactly designed.  |

|

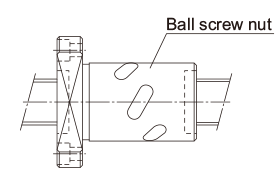

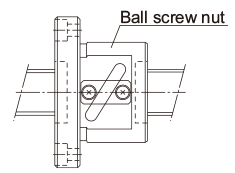

Comparison between the Offset Preload Type of Simple-Nut Ball Screw and the Oversized-ball Preload Nut Ball Screw

| Simple-Nut Ball Screw Model DIK | Conventional Oversized-ball Preload Nut Ball Screw Model BNF |

|---|---|

|

|

| Preloading Structure | |

|

|

| Accuracy Life | |

|

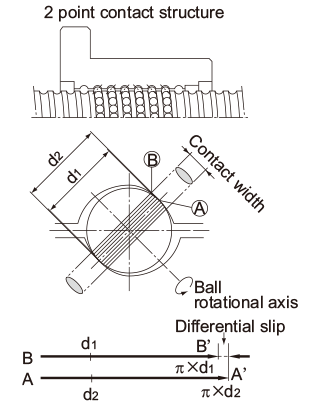

Simple-Nut Ball Screw model DIK has a similar preloading structure to that of the double-nut type although the former only has one ball screw nut. As a result, no differential slip or spin occurs, thus minimizing the increase in the rotational torque and the generation of heat. Accordingly, a high level of accuracy can be maintained over a long period.  |

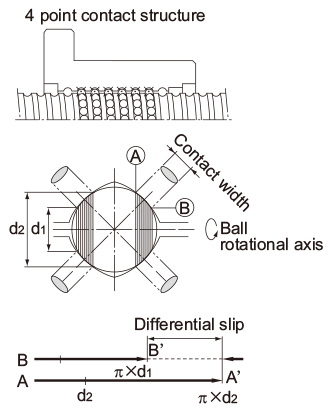

With the oversized-ball preload nut ball Screw, a preload is provided through each of the balls in contact with the raceway at four points. This causes differential slip and spin increasing the rotational torque, resulting in accelerated wear and heat generation.Therefore, the accuracy deteriorates in a short period.  |

Point of Selection

- Conditions of the Ball Screw

- Conditions of the Ball Screw

- Estimating the shaft length

- Selecting lead・Selecting a shaft diameter

- Method for Mounting the Ball Screw Shaft

- Permissible Axial Load

- Permissible Rotational Speed

- Selecting a Nut

- Calculating the permissible axial load

- Considering the Service Life

- Studying the Rigidity

- Studying the Positioning Accuracy

- Studying the Rotational Torque

- Studying the Driving Motor