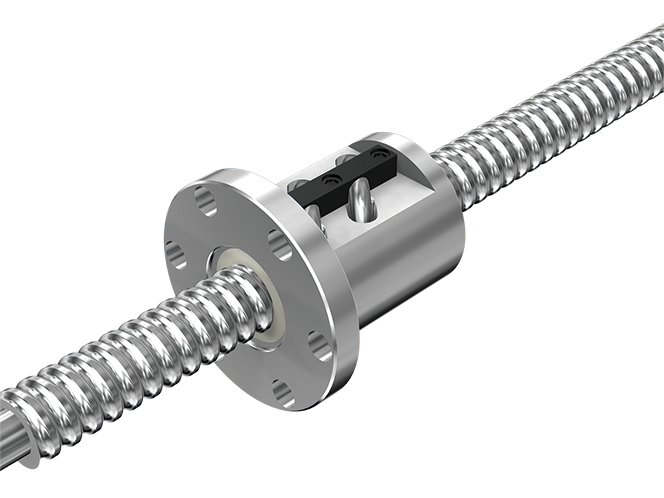

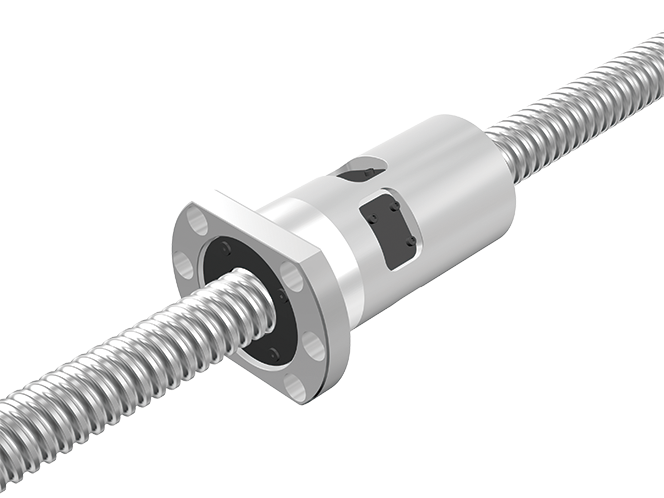

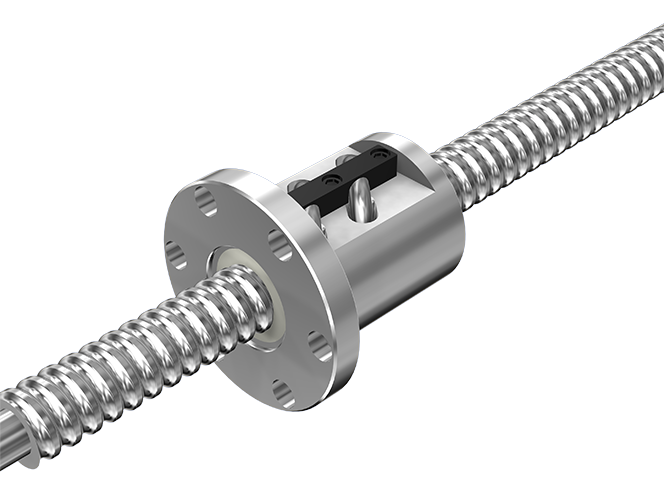

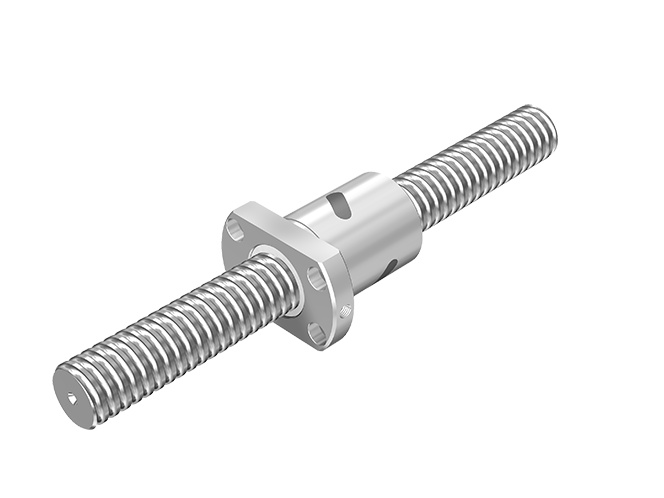

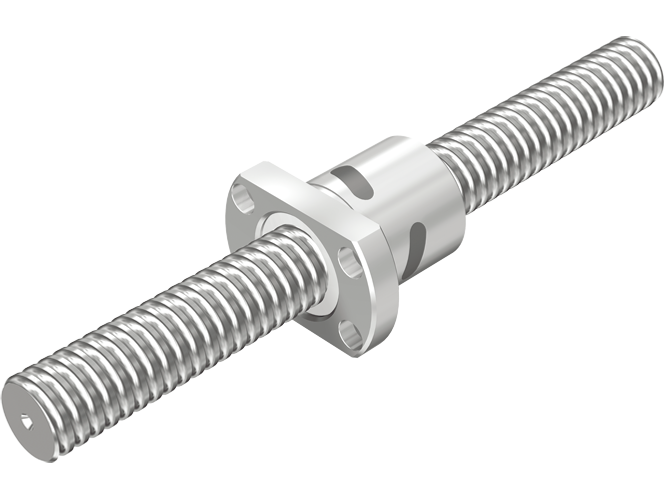

Full-Ball Type Precision Ball Screw

For THK precision ball screws, a wide array of precision-ground screw shafts and ball screw nuts are available as standard to meet diversified applications.

Types

Highlight feature tags

- Compact

- Miniature

- For machine tools

- High speed

- Super lead

- Large lead

- Preload

- No preload

- Offset preload

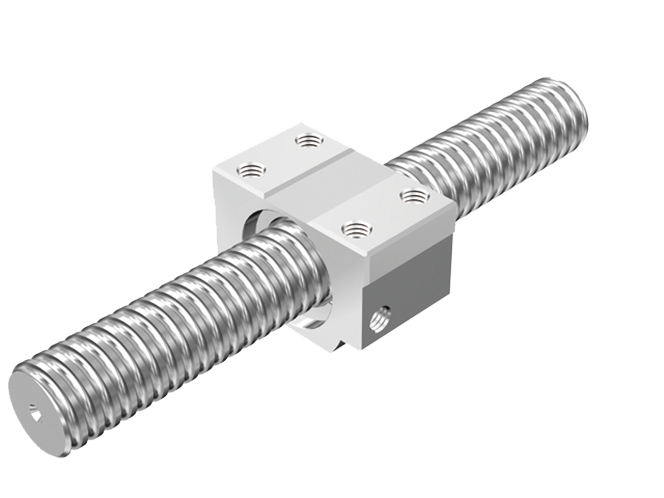

- Return-pipe type

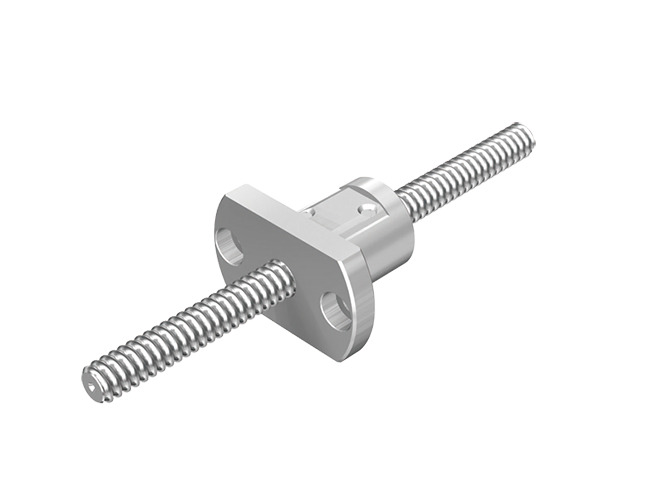

- End-cap type

- Deflector type

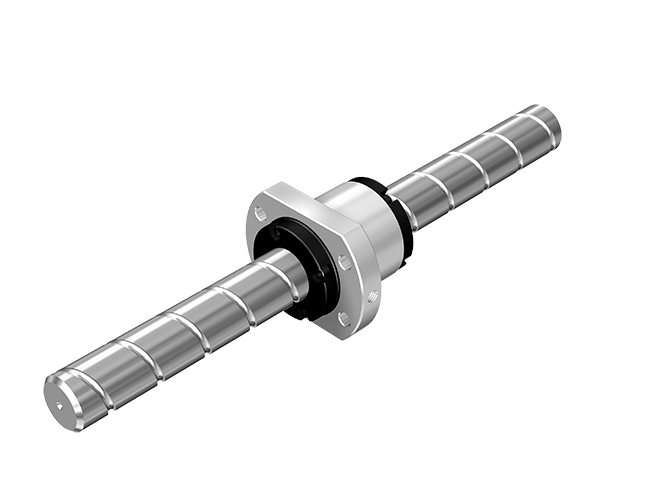

- Double nut

- Slim nut

- Square nut

- Precision positioning (ball screw)

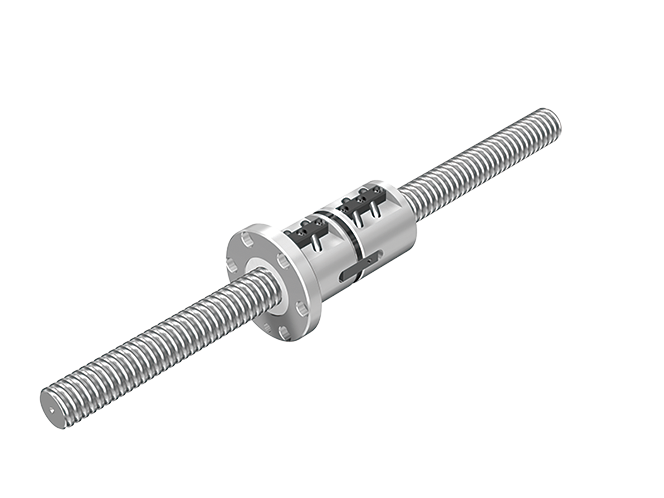

- Double nut preload

- Precision positioning (ball screw)

- Preload

- Offset preload

- High speed

- Compact

- For machine tools

Screw shaft diameter (mm) : 36,40,45,50,63

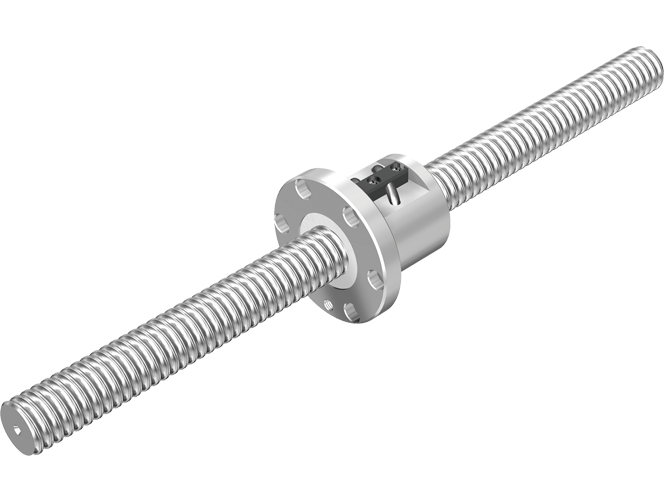

- Precision positioning (ball screw)

- Preload

- Offset preload

- High speed

Screw shaft diameter (mm) : 16,20,25,28,32,36,40,45,50

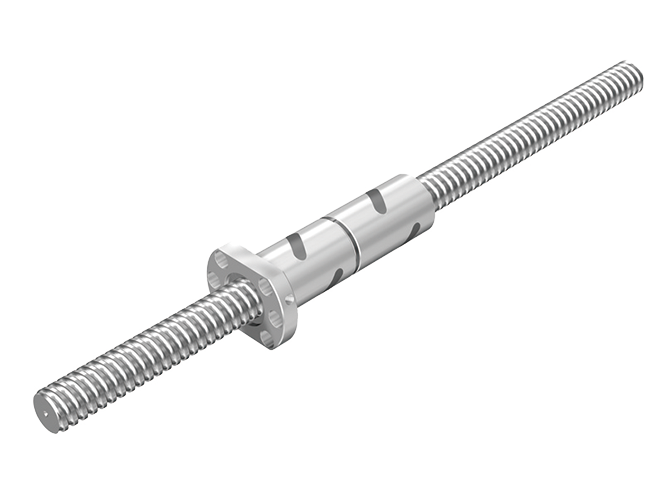

- Precision positioning (ball screw)

- Preload

- Offset preload

- Compact

- Deflector type

- Slim nut

Screw shaft diameter (mm) : 14,16,20,25,28,32,36,40,50,63

- Precision positioning (ball screw)

- Preload

- Double nut preload

- High speed

- Double nut

Screw shaft diameter (mm) : 16,28,32,36,40,45,50

- Precision positioning (ball screw)

- Preload

- Double nut preload

- Return-pipe type

- Double nut

Screw shaft diameter (mm) : 55,63,70,80,100

- Precision positioning (ball screw)

- Preload

- Double nut preload

- Compact

- Deflector type

- Double nut

- Slim nut

Screw shaft diameter (mm) : 40,50,63

- Precision positioning (ball screw)

- Large lead

- Preload

- Double nut preload

- End-cap type

- Double nut

Screw shaft diameter (mm) : 15,16,20,25,32,36,40,50

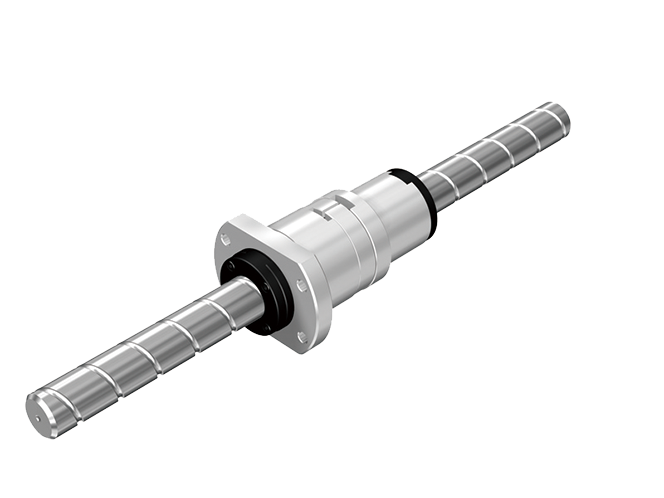

- Precision positioning (ball screw)

- No preload

- High speed

Screw shaft diameter (mm) : 16,20,25,28,32,36,40,45,50

- Precision positioning (ball screw)

- No preload

- Return-pipe type

Screw shaft diameter (mm) : 55,63,70,80,100

- Precision positioning (ball screw)

- No preload

- Compact

- Deflector type

- Slim nut

Screw shaft diameter (mm) : 14,16,20,25,28,32,40,50,63

- Precision positioning (ball screw)

- Super lead

- No preload

- High speed

- End-cap type

Screw shaft diameter (mm) : 15,20,25

- Precision positioning (ball screw)

- Super lead

- No preload

- End-cap type

Screw shaft diameter (mm) : 08,10,13,15,20,25,30,40,50

- Precision positioning (ball screw)

- No preload

- Compact

- Miniature

- Deflector type

Screw shaft diameter (mm) : 04,06,08,10,12,14

- Precision positioning (ball screw)

- No preload

- Return-pipe type

- Square nut

Screw shaft diameter (mm) : 14,16,18,20,25,28,32,36,45

- Precision positioning (ball screw)

- No preload

- Compact

- Miniature

Screw shaft diameter (mm) : 04,06,08,10,12,14

- Precision positioning (ball screw)

- Large lead

- No preload

- End-cap type

Screw shaft diameter (mm) : 08,15,16,20,25,32,36,40,50

Features

For THK precision ball screws, a wide array of precision-ground screw shafts and ball screw nuts are available as standard to meet diversified applications.

Structure and Features

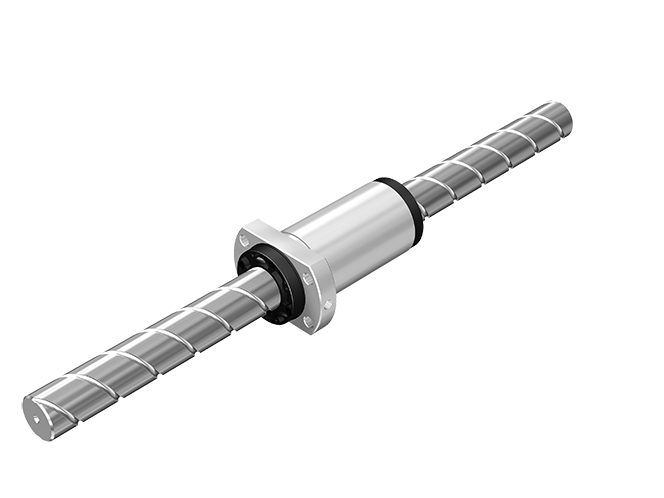

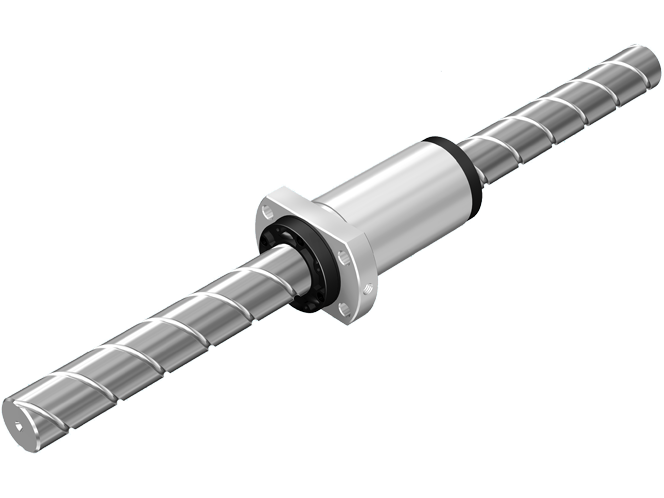

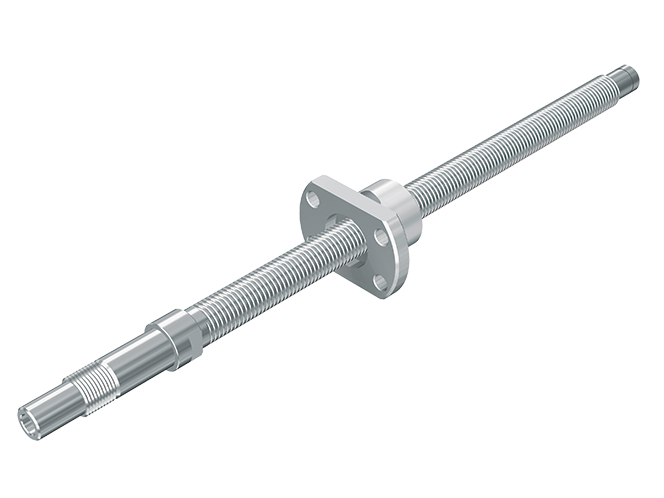

Combinations of Various Shaft Diameters and Leads

You can select the combination of a shaft diameter and a lead that meets the intended use from the various nut types and the screw shaft leads. Those nut types include the return-pipe nuts, which represent the most extensive variations among the series, the compact simple nuts, and the large-lead end cap nuts.

Screw Shaft Standard Products (Unfinished Shaft Ends/Finished Shaft Ends) Available

The unfinished shaft end types, which are mass-produced by cutting the standardized screw shafts to fixed lengths, and those with finished shaft ends, for which the screw shaft ends are machined to match the corresponding support units, are available as standard.

Accuracy Standards Compliant with JIS (ISO)

The precision of the ball screw is controlled in accordance with JIS B 1192 (ISO 3408).

|

Precision Ball Screw |

||||||||

|---|---|---|---|---|---|---|---|---|

|

Rolled Ball Screw |

||||||||

|

Accuracy grades |

C0 |

C1 |

C2 |

C3 |

C5 |

C7 |

C8 |

C10 |

|

Type |

Series code |

Grade |

Remarks |

|---|---|---|---|

|

For positioning |

C |

0, 1, 3, 5 |

JIS series |

|

Cp |

1,3,5 |

ISO compliant |

|

|

For transport |

Ct |

1, 3, 5, 7, 10 |

Accessories that Match the Operating Environment are Available

Accessories are available, including a lubricator (QZ), which enables the maintenance interval to be significantly extended, and a wiper ring (W), which improves the ability to remove foreign materials in adverse environments.