Studying the Rotational Torque

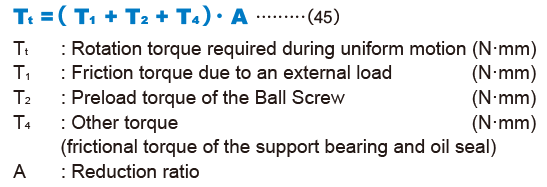

The rotational torque required to convert rotational motion of the Ball Screw into straight motion is obtained using the equation (45) below.

During Uniform Motion

During Acceleration

During Deceleration

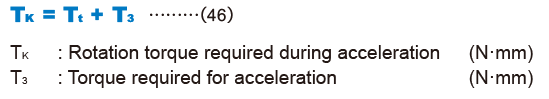

Frictional Torque Due to an External Load

Of the turning forces required for the Ball Screw, the rotational torque needed for an external load (guide surface resistance or external force) is obtained using the equation (48) below.

Torque Due to a Preload on the Ball Screw

For a preload on the Ball Screw, see "Preload Torque" on Preload.

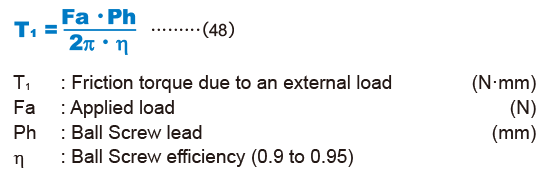

Torque Required for Acceleration

Investigating the Terminal Strength of Ball Screw Shafts

When torque is conveyed through the screw shaft in a ball screw, the strength of the screw shaft must be taken into consideration since it experiences both torsion load and bending load.

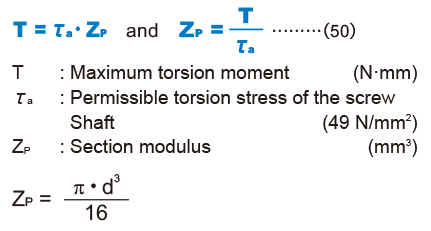

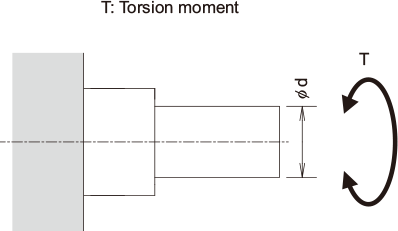

Screw shaft under torsion

When torsion load is applied to the end of a ball screw shaft, use equation (50) to obtain the end diameter of the screw shaft.

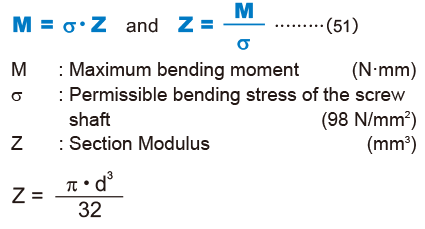

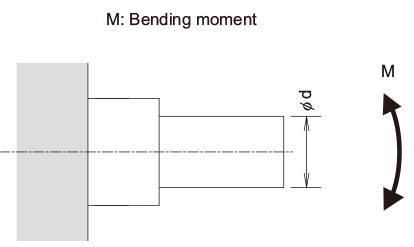

Screw shaft under bending

When bending load is applied to the end of a ball screw shaft, use equation (51) to obtain the end diameter of the screw shaft.

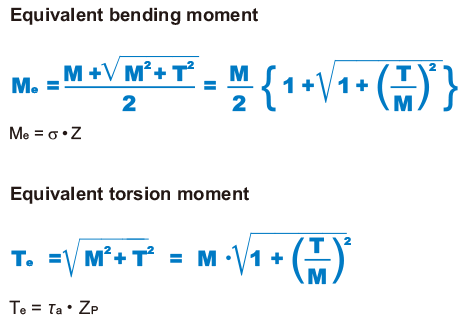

If the shaft experiences both torsion and bending

When torsion load and bending load are both applied simultaneously to the end of a ball screw shaft, calculate the diameter of the screw shaft separately for each, taking into consideration the corresponding bending moment (Me) and the corresponding torsion moment (Te). Then calculate the thickness of the screw shaft and use the largest of the values.

Point of Selection

- Conditions of the Ball Screw

- Conditions of the Ball Screw

- Estimating the shaft length

- Selecting lead・Selecting a shaft diameter

- Method for Mounting the Ball Screw Shaft

- Permissible Axial Load

- Permissible Rotational Speed

- Selecting a Nut

- Calculating the permissible axial load

- Studying the Service Life

- Studying the Rigidity

- Studying the Positioning Accuracy

- Studying the Rotational Torque

- Studying the Driving Motor