Studying the Driving Motor

When selecting a driving motor required to rotate the Ball Screw, normally take into account the rotational speed, rotational torque and minimum feed amount.

When Using a Servomotor

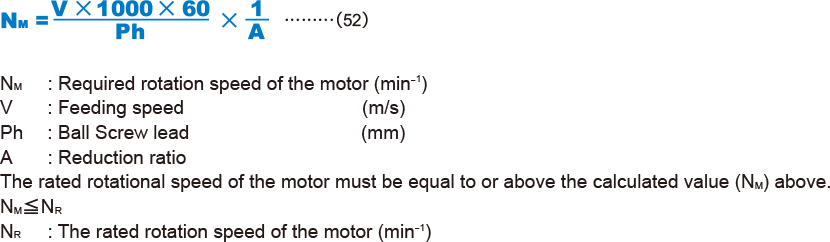

Rotational Speed

The rotation speed required for the motor is obtained using the equation (52) based on the feed speed, Ball Screw lead and reduction ratio.

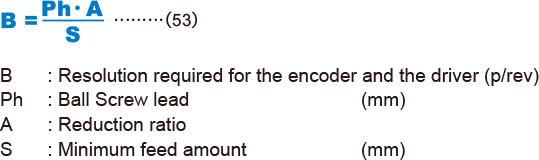

Required Resolution

Resolutions required for the encoder and the driver are obtained using the equation (53) based on the minimum feed amount, Ball Screw lead and reduction ratio.

Motor Torque

The torque required for the motor differs between uniform motion, acceleration and deceleration. Tocalculate the rotational torque, see "Studying the Rotational Torque" .

- Maximum torque

The maximum torque required for the motor must be equal to or below the maximum peak torque of the motor.

Tmax ≦ Tpmax

Tmax : Maximum torque acting on the motor

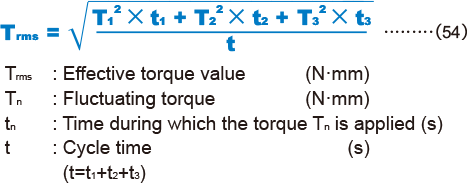

Tpmax : Maximum peak torque of the motor - Effective torque value

The effective value of the torque required for the motor must be calculated. The effective value of the torque is obtained using the equation (54).

The calculated effective value of the torque must be equal to or below the rated torque of the motor.

Trms≦TRTR : Rated torque of the motor (N・mm)

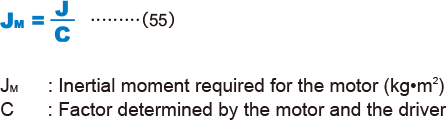

Inertial Moment

The inertial moment required for the motor is obtained using the equation (55).

(It is normally between 3 to 10. However, it varies depending on the motor and the driver. Check the specific value in the catalog by the motor manufacturer.)

The inertial moment of the motor must be equal to or above the calculated JM value.

When Using a Stepping Motor (Pulse Motor)

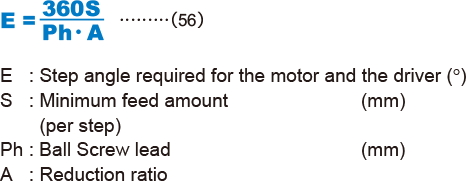

Minimal Feed Amount(per Step)

The step angle required for the motor and the driver is obtained using the equation (56) based on the minimum feed amount, Ball Screw lead and reduction ratio.

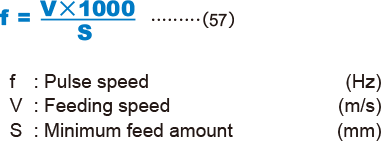

Pulse Speed and Motor Torque

- Pulse speedThe pulse speed is obtained using the equation (57) based on the feed speed and the minimum feed amount.

- Torque required for the motor The torque required for the motor differs between the uniform motion, the acceleration and the deceleration. To calculate the rotational torque, see "Studying the Rotational Torque".

Thus, the pulse speed required for the motor and the required torque can be calculated in the manner described above.Although the torque varies depending on the motors, normally the calculated torque should be doubled to ensure safety. Check if the torque can be used in the motor’s speed-torque curve.

Point of Selection

- Conditions of the Ball Screw

- Conditions of the Ball Screw

- Estimating the shaft length

- Selecting lead・Selecting a shaft diameter

- Method for Mounting the Ball Screw Shaft

- Permissible Axial Load

- Permissible Rotational Speed

- Selecting a Nut

- Calculating the permissible axial load

- Studying the Service Life

- Studying the Rigidity

- Studying the Positioning Accuracy

- Studying the Rotational Torque

- Studying the Driving Motor