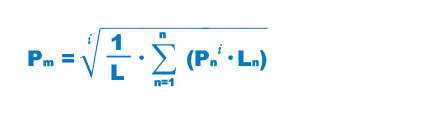

Average Load

In cases where the load applied to each LM block fluctuates under different conditions, such as an industrial robot holding a work with its arm as it advances and receding with its arm empty, and a machine tool handling various workpieces, it is necessary to calculate the service life of the LM Block while taking into account such fluctuating loading conditions.The average load (P m) is the load under which the service life of the LM Guide is equivalent to that under varying loads applied to the LM blocks.

| Pm | Average Load (N) |

|---|---|

| Pn | Varying load (N) |

| L | Total travel distance (mm) |

| Ln | Distance traveled under load Pn(mm) |

| i | Constant determined by rolling element |

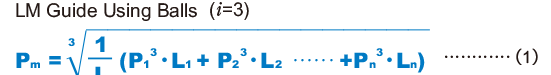

Note) The above equation or the equation (1) below applies when the rolling elements are balls.

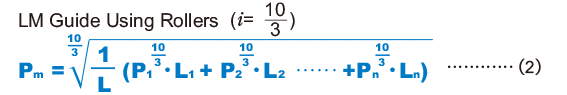

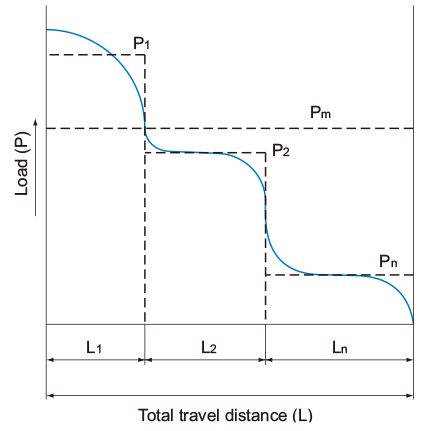

- When the load fluctuates stepwise

Pm Average Load (N) Pn Varying load (N) L Total travel distance (mm) Ln Distance traveled under Pn (mm)

Pm Average Load (N) Pn Varying load (N) L Total travel distance (mm) Ln Distance traveled under Pn (mm)

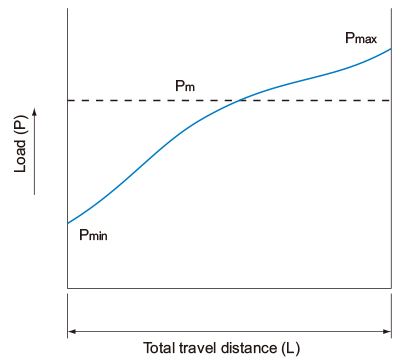

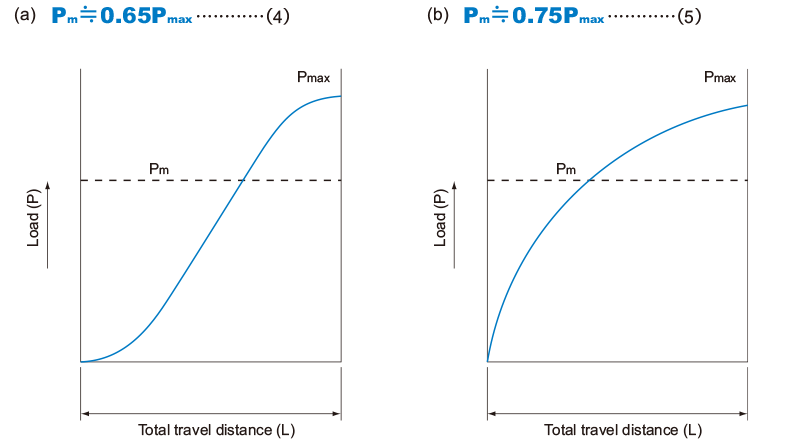

- When the load fluctuates monotonically

Pmin Minimum load (N) Pmax Maximum load (N)

- When the load fluctuates sinusoidally

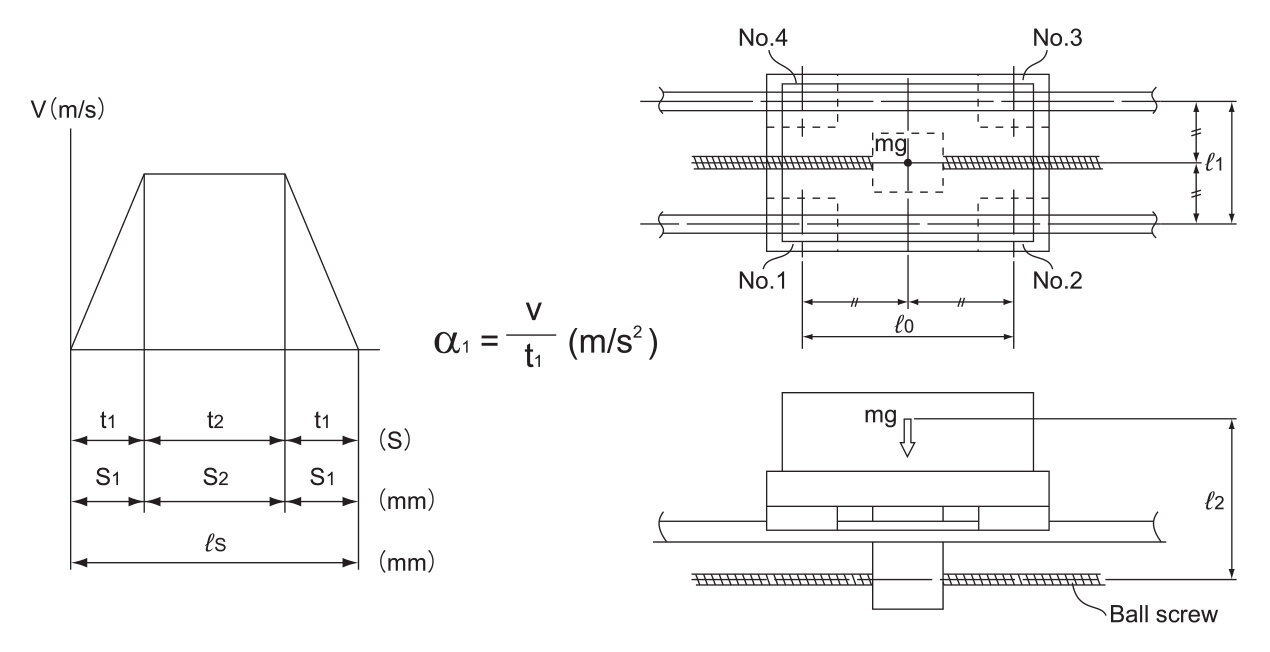

Example of Calculating the Average Load (1)

- with Horizontal Mount and Acceleration/Deceleration Considered -

Conditions

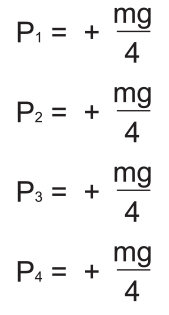

Load Applied to the LM Block

●During uniform motion

●During acceleration

●During deceleration

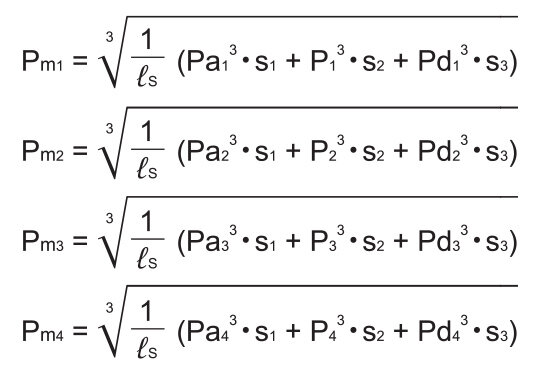

Average load

Note) Pan and Pdn represent loads applied to each LM block. The suffix “n” indicates the block number in the diagram above.

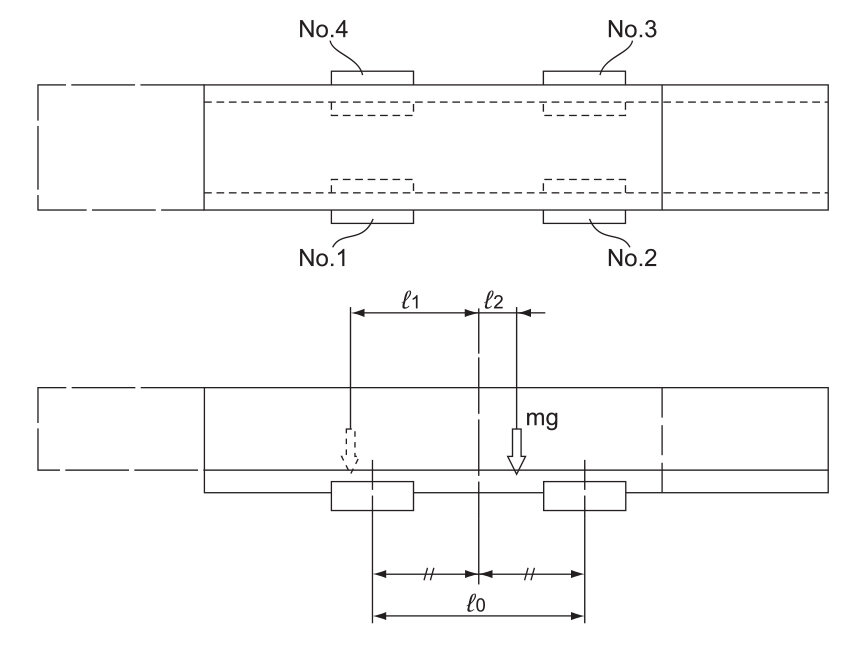

Example of Calculating the Average Load (2) - When the Rails are Movable

Conditions

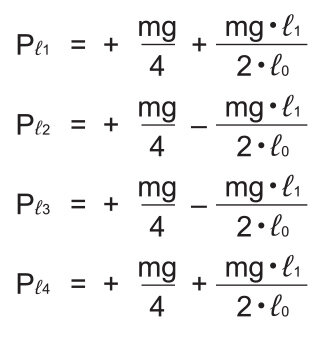

Load Applied to the LM Block

●At the left of the arm

●At the right of the arm

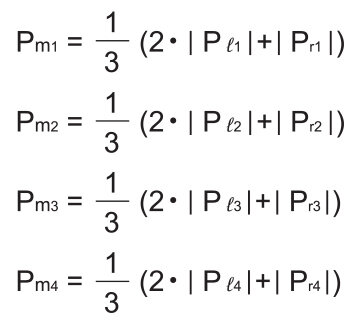

Average load

Note) Pℓn and Prn represent loads applied to each LM block. The suffix “n” indicates the block number in the diagram above.