Prediction the Rigidity

Selecting a Radial Clearance (Preload)

Since the radial clearance of an LM Guide greatly affects the running accuracy, load carrying capacity and rigidity of the LM Guide, it is important to select an appropriate clearance according to the application. In general, selecting a negative clearance (i.e., a preload* is applied) while taking into account possible vibrations and impact generated from reciprocating motion favorably affects the service life and the accuracy. For specific radial clearances, contact THK. We will help you select the optimal clearance according to the conditions. The clearances of all LM Guide models (except model HR, GSR and GSR-R, which are separate types) are adjusted as specified before shipment, and therefore they do not need further preload adjustment.

*Preload is an internal load applied to the rolling elements (balls, rollers, etc.) of an LM block in advance in order to increase its rigidity.

| Normal Clearance | Clearance C1 (Light Preload) | Clearance C0 (Medium Preload) | |

|---|---|---|---|

| Condition |

|

|

|

| Examples of applications |

|

|

|

Service Life with a Preload Considered

When using an LM Guide under a medium preload (clearance C0), it is necessary to calculate the service life while taking into account the magnitude of the preload. To identify the appropriate preload for any selected LM Guide model, contact THK.

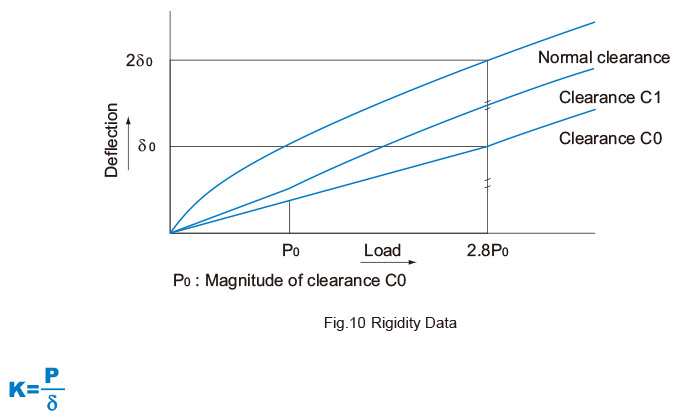

Rigidity

When a load is applied to an LM Guide, the bearings and LM block will elastically deform within the allowable load range. The ratio of displacement to applied load is referred to as "rigidity." The radial internal clearance (preload) for the LM Guide can be specified in order to reduce displacement. By using balls larger than the width of the race, they will naturally deform elastically as they roll, allowing the load to be maintained for longer while limiting displacement in the LM Guide. The effect of the preload can be up to 2.8 times greater than the size of the preload itself. If that level is exceeded, the preload is released and the effect of the preload is lost. When a preloaded LM Guide takes an external load, the displacement will be linear. The level ofdisplacement will be approximately half that of an LM Guide with no preload. The preload, in addition to reducing displacement, helps prevent premature failure due to vibration and impact/shock.

| K | Rigidity value (N/μm) |

|---|---|

| δ | Deflection (μm) |

| P | Calculated load (N) |