Determining the Accuracy

Accuracy Standards

Accuracy of the LM Guide is specified in terms of running parallelism, dimensional tolerance for height and width, and height and width difference between a pair when 2 or more LM blocks are used on one rail or when 2 or more rails are mounted on the same plane. For details, see "Accuracy Standard for Each Model"

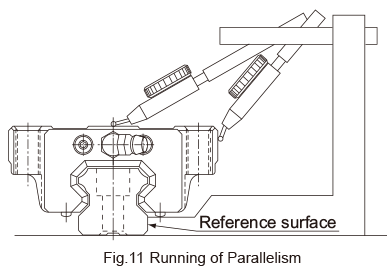

Running of Parallelism

It refers to the tolerance for parallelism between the LM block and the LM rail reference surface when the LM block travels the whole length of the LM rail with the LM rail secured on the reference reference surface using bolts.

Difference in Height M

Indicates a difference between the minimum and maximum values of height (M) of each of the LM blocks used on the same plane in combination.

Difference in Width W2

Indicates a difference between the minimum and maximum values of the width (W 2) between each of the LM blocks, mounted on one LM rail in combination, and the LM rail.

-

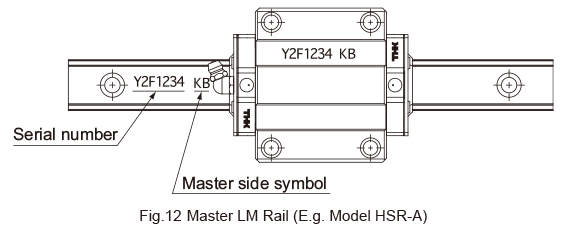

Note 1) When two or more rails are used on the same plane in parallel, this applies only to the difference in width (W2) and dimensional tolerance of the master rail. Please specify if you wish for it to apply to the difference in width and dimensional tolerance of the subsidiary rail as well. Master LM rails will have a serial number ending with "KB" printed on them. However, this is not the case for standard grade products.

- Note 2) Accuracy measurements each represent the average value of the central point or the central area of the LM block.

- Note 3) If it is mounted on a less rigid base such as an aluminum base, the curve of the rail will affect the accuracy of the machine. Therefore, it is necessary to define straightness of the rail in advance.

Guidelines for Accuracy Grades by Machine Type

Table13 shows guidelines for selecting an accuracy grade of the LM Guide according to the machinetype.

| Type of machine | Accuracy grades | |||||

|---|---|---|---|---|---|---|

| Normal | H | P | SP | UP | ||

| Machine tool | Machining center | ● | ● | |||

| Lathe | ● | ● | ||||

| Milling machine | ● | ● | ||||

| Boring machine | ● | ● | ||||

| Jig borer | ● | ● | ||||

| Grinding machine | ● | ● | ||||

| Electric discharge machine | ● | ● | ● | |||

| Punching press | ● | ● | ||||

| Laser beam machine | ● | ● | ● | |||

| Woodworking machine | ● | ● | ● | |||

| NC drilling machine | ● | ● | ||||

| Tapping center | ● | ● | ||||

| Palette changer | ● | |||||

| ATC | ● | |||||

| Wire cutting machine | ● | ● | ||||

| Dressing machine | ● | ● | ||||

| Industrial robot |

Cartesian coordinate | ● | ● | ● | ||

| Cylindrical coordinate | ● | ● | ||||

| Semiconductor manufacturing equipment |

Wire bonding machine | ● | ● | |||

| Prober | ● | ● | ||||

| Electronic component inserter | ● | ● | ||||

| Printed circuit board drilling machine | ● | ● | ● | |||

| Other equipment | Injection molding machine | ● | ● | |||

| 3D measuring instrument | ● | ● | ||||

| Office equipment | ● | ● | ||||

| Conveyance system | ● | ● | ||||

| XY table | ● | ● | ● | |||

| Coating machine | ● | ● | ||||

| Welding machine | ● | ● | ||||

| Medical equipment | ● | ● | ||||

| Digitizer | ● | ● | ● | |||

| Inspection equipment | ● | ● | ● | |||

- Normal : Normal grade

- SP : Super precision grade

- H : High accuracy grade

- UP : Ultra precision grade

- P : Precision grade