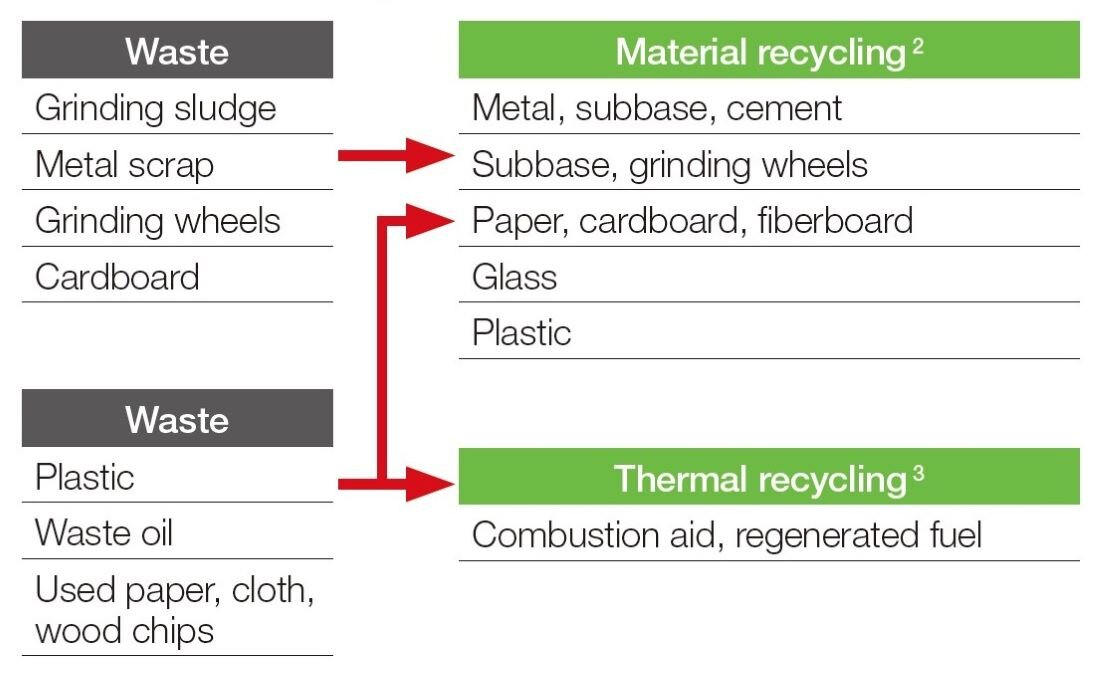

Promotion of Waste Reduction and Recycling

Initiatives for Achieving Zero Emissions

With our zero emissions activities, we aim to reduce all forms of

waste we generate to zero. We promote zero emissions activities

through controlling the use of direct and indirect materials,

emissions and final waste, and reusing and recycling.

The waste produced by our business activities includes

metal scrap, oil and liquid waste, grinding sludge, packaging,

and plastic waste. By thoroughly separating our waste, we reuse

or transform it into usable materials, such as steel-making

material, cement material, and recycled fuel. Reducing plastic

waste has garnered particular attention in recent years. THK is

making steady strides in reducing the amount of plastic waste

we generate by reusing and recycling plastics used in our

production processes and utilizing returnable boxes that can be

reused.

THK Japan aims for an emissions rate (volume of waste

disposed/total discharged) of less than 0.50%. Continuing from

the successful achievement of this goal in 2023, we met this

goal again in 2024 with an emissions rate of 0.21%.

2 Thermal recycling: Using waste as combustion material

Activities and Results Related to Plastic Waste

Efforts at Each Facility

Wuxi (China)

Shaving Solidification Equipment

A briquetting press was installed in May to solidify and recycle the shavings from cutting processes. As a result, 420,000 kg of material was recycled over the year.

Installed Water-Soluble Waste Fluid Treatment System

A water-soluble waste fluid treatment system was installed in March for reusing the plant's waste oil. As a result, water-soluble liquid waste was reduced by 300 kL per year.

DALIAN THK (China)

Packaging Improvement

Per-box packaging quantities were reevaluated with customer permission. This resulted in 144 kg fewer boxes being used per year.