Quality Assurance Structure

Basic Stance/Policy

Quality Policy

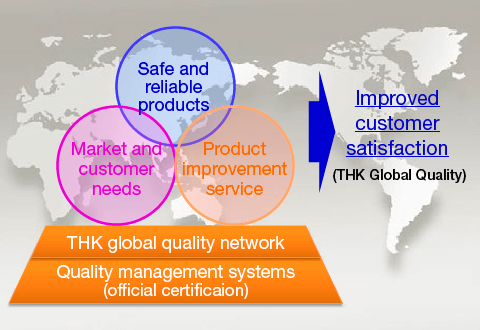

We supply reliable and safe products of superior quality to all customers and provide a complete quality assurance system with global considerations in mind.

Quality Assurance Structure

THK has established a quality assurance system in which each production facility both in and outside of Japan is certified with the ISO 9001 Quality Management System. We provide a quality assurance system for the industrial machinery business that produces components used in machine tools, semiconductor manufacturing equipment, medical devices, robots, logistics equipment, and seismic isolation and damping systems. With this as our base, we obtain certifications in quality standards adapted for new fields such as the automotive and transportation business and the aerospace industry.

We also work with each of our suppliers to accomplish environmentally conscious manufacturing that takes ESG and the SDGs into consideration.

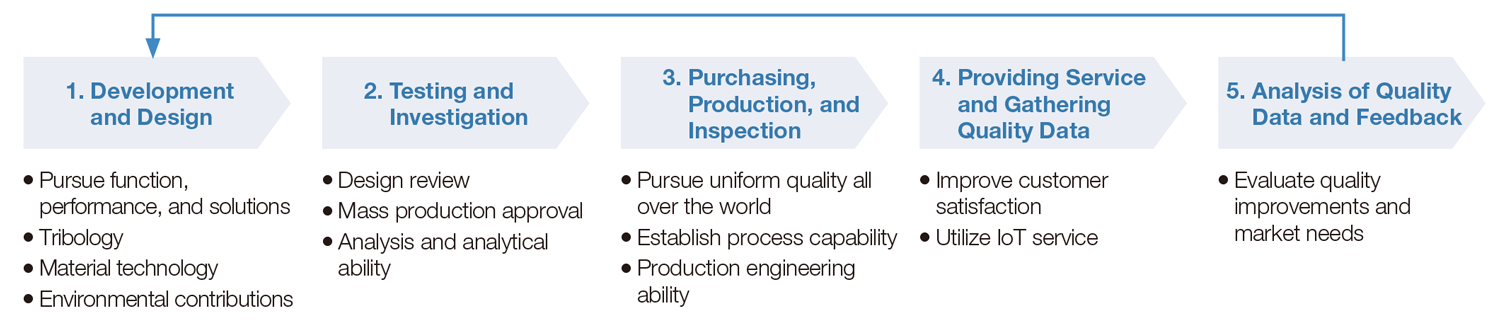

The following initiatives are being undertaken to strengthen quality at THK.

- 1. Strengthening design quality

- 2. Strengthening product quality

- 3. Strengthening production quality

- 4. Strengthening talent development

As part of managing our product development process, we review the solutions implemented for any issues during the planning, design, prototype, trial, and mass-production stages, and we work to manage the stability and maintenance of quality levels after mass production.

We have established a system that allows quality data to be shared globally. In addition to gathering feedback from customers in each region, analyzing it, and providing rapid and appropriate service as a manufacturing and innovative services company, we endeavor to develop products that meet market needs and improve quality.

We endeavor to enhance the quality of the measurements we take, keeping error to a minimum, by implementing optimal measuring equipment necessary for maintaining product quality.

In order to make products that are reliable and safe, we strive to develop talent in the areas of product knowledge (technology), equipment handling (technique), and optimal production (quality).

Quality Management System Certification Status

|

ISO9001 |

JIS Q 9100

|

IATF16949

|

|

|

Japan |

11 |

1 |

4 |

|---|---|---|---|

|

Outside of Japan |

13 |

- |

7 |

|

Total |

24 |

1 |

11 |

Efforts at Each Facility

THK NIIGATA

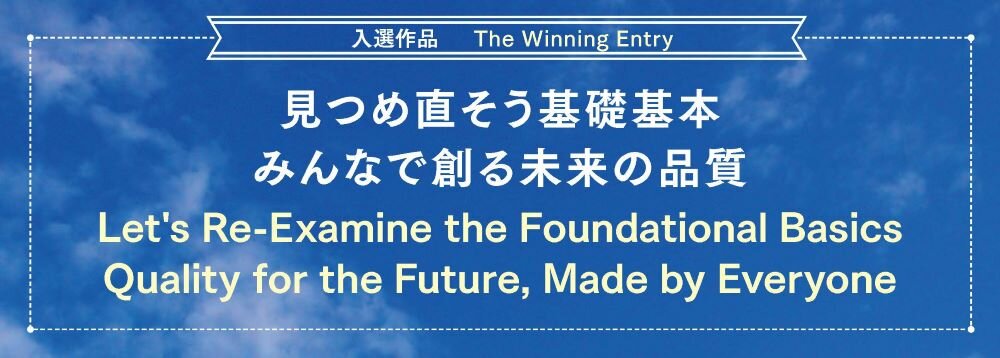

Award

During the 64th Quality Month slogan contest sponsored by the Japan Science Foundation that was held in November, a slogan created by Airi Shirakura from the Quality Assurance Section was selected from among 2,493 total submissions.

Changzhou (China)

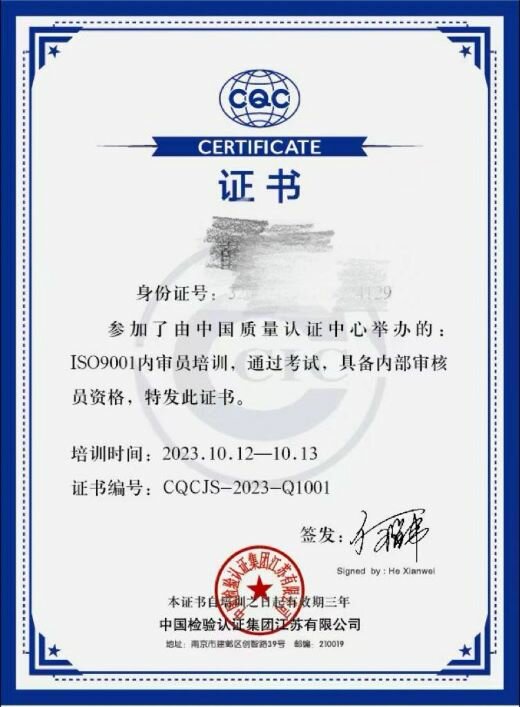

ISO 9001 Internal Auditor Certification

In order to bolster this facility’s internal auditing capabilities, an external instructor was invited to conduct training in October. Twenty-two members participated, and all of them were awarded with ISO 9001 internal auditor certification.

Improving Knowledge of Quality Control

Internal quality control training was conducted over three sessions in March, July, and September to boost employee knowledge of this subject. A total of 71 staff members participated, and all of them passed an internal test.