Local Communities

Basic Stance/Policy

As a good corporate citizen, our company actively contributes to society. Our activities include:

- Establishing a basic philosophy of contributing to society through our business activities

- Identifying areas to prioritize our efforts and using our corporate resources to promote specific contributions based on our corporate philosophy

- Coordinating and cooperating with various stakeholders, including NPOs, NGOs, local communities, governments, and international institutions

- Supporting employees' own community contributions and involvement

- Participating in the social efforts of the industry and business community

Activities and Results

Coexisting with Local Communities

Efforts at Each Facility

THK INTECHS Sendai Plant

Award

In recognition of many years spent contributing to maintaining order in traffic safety as a traffic safety officer, Masahiro Ishikawa from the Plant Administration Section received the Tohoku Honorary Traffic Award from the Miyagi Prefecture Traffic Safety Association in November.

NIPPON SLIDE

Award

In Adachi Ward, the public community and corporations have come together to expand “Beautiful Windows” activities with the goal of creating a safe and secure town free of crime. NIPPON SLIDE was highly commended and received an award for the waste reduction and proper disposal activities it conducted in 2023.

TMA (USA)

Opening the Plant to the Public

In October, the plant grounds were opened to hold a Trunk-or-Treat event*1. TMA created a robot to distribute candy, and 300 members from the local community (200 of which were children) visited and spent a fun day together.

*1Trunk-or-Treat: A trick-or-treating event where candy is passed out from cars with festive Halloween decorations.

THK America

THK America carried out holiday food assistance activities and donated 971 food and hygiene items to the Schaumburg Food Pantry. The donation items were enough to pack two SUVs full.

TRA CZECH (Czech Republic)

Protecting the beetles and butterflies

TRA CZECH has performed manual mowing and hay collection aimed at protecting the beetles and butterflies that live in the meadow around Kleneční Hill. This area has been used by companies as a waste disposal site in the past (40 years ago and even further back), and TRA CZECH is now trying to restore biodiversity to this area and ensure that the original use does not have a negative impact on the environment.

Efforts at Each Facility

Looking ahead to the future, THK is proactively creating spaces for interacting with younger talent with the goal of passing techniques on to the next generation.

THK Education Outreach Program

The THK Education Outreach Program was launched in 2017 out of a desire to introduce children to the joy of manufacturing. We hope to inspire students to become interested in manufacturing by providing classrooms with educational opportunities to develop their students’ cognitive, decision-making, and presentation skills through manufacturing. We are cultivating talent that can create and develop things to solve real-life problems and social challenges through manufacturing.

METI Children’s Day

The Ministry of Economy, Trade and Industry sponsors Children’s Day as an opportunity for children to learn about society through hands-on activities. At this event, we exhibited one of our materials for exploring manufacturing, our “make an auto-sorting trash can for recycling” activity, that was developed for our Educational Outreach Program. By programming sensors and motors to control and create a robot that separates drink bottles, the children learned about mechanical systems and how fun it is to make things.

Manufacturing Experience Stadium

The Nikkan Kogyo Shimbun held a hands-on workshop in August to introduce the next generation to the joy of manufacturing. During the event, we exhibited our “make an auto-sorting trash can for recycling” activity, and children were challenged to engage with all the stages of manufacturing, from developing and assembling to verifying and refining. The children repeatedly tested out and made tweaks to the robot they created as they worked to solve the challenge they were given.

THK NIIGATA

Plant Visit

In October, 78 first-year students and six teachers, 84 visitors in all, participated in a plant tour as part of Yasuda Middle School’s “Learn About Local Businesses” curriculum. Divided into six groups, they gained a deeper appreciation for the value of work and contributing to society during their tour.

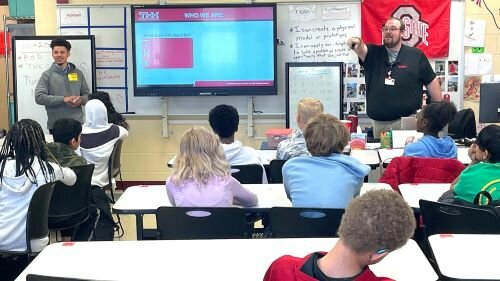

TMA (USA)

| Who | When | Objective | Notes |

|---|---|---|---|

Twenty-six high school students learning about robotics and manufacturing through C-TEC's RAM Program |

February |

To introduce TMA as part of an educational outreach program |

One of the visiting students is now a TMA employee |

Thirty students from Lakewood High School |

March |

For students to see with their own eyes what they have learned about in guest lessons |

|

Twenty-eight sixth- through tenth-grade students from the village of New Lexington’s New Lexington Middle School and New Lexington High School |

November |

For students to learn about manufacturing and technology |

|

Twenty students from The Ohio State University’s engineering program |

November |

For students to talk with employees about manufacturing |

|

Twenty-four ninth- through twelfth-grade students from Sheridan High School |

November |

For students to talk with employees about LM Guide technology |

C-TEC

New Lexington Middle School and New Lexington High School

Sheridan High School

Wuxi Plant (China)

Internships

From January to November, 110 people participated in internships offered for technical school students.

Guest Lessons

TMA

Newark City Area

In January and February, students at five elementary schools (Carson, John Clem, Franklin, McGuffey, and Ben Franklin) learned about friction and how critical THK's LM Guide is for smooth linear motion. In January, technical support and components were provided to high school robotics clubs to teach students about THK’s technology.

Johnstown City Area

TMA participated in Johnstown’s Manufacturing Day, presenting on THK’s products and the places where they are used and giving a programming demonstration to a total of 250 fourth- and fifth-grade students from Johnstown Intermediate School.

Pataskala City Area

In February, 160 students in Licking Heights Middle School’s basic engineering program were introduced to THK technology and special features of LM Guide products over the course of five class sessions.

Heath City Area

In February, a class on THK products was taught to 20 students studying STEM (science, technology, engineering, and mathematics) fields at Heath Middle School.

Hebron Village Area

In March, a class about manufacturing and engineering careers at TMA was held for 30 students studying engineering at Lakewood High School. Then in October, a class on the LM Guide and LM Guide technology was held for 30 of the school's students studying STEM fields.

C-TEC

In July, TMA participated in the C-TEC summer camp that it sponsors, teaching the 60 student campers about THK technology and the LM Guide over the course of four lessons.

Utica Village Area

In September, a class on the LM Guide and LM Guide technology was held for 10 students at Utica High School.

Central Ohio Area

In December, support for constructing electrical circuit boards was provided to 10 students studying STEM fields at The Ohio State University.

Supporting Education

THK Education Outreach Program

The THK Education Outreach Program began in 2017 as a special project in anticipation of our 50th anniversary in 2021 and with the desire to introduce children to the joy of manufacturing. The project has been ongoing for over five years and is now in its seventh year. We provide educational opportunities to schools that foster cognitive, decision-making, and presenting skills through manufacturing. The objective is to cultivate talent that can create and develop, thinking about issues with classmates and arriving at solutions for unanswered problems.

In 2022, we added a sorting factor onto the theme of the "a trash can that you want to use" lesson idea that was solicited internally and developed the "making an auto-sorting trash can for recycling" lesson. We defined that as one of our educational materials for exploring manufacturing, recruited trial schools, and have received great feedback from teachers and students. Going forward, we will proceed with distribution to schools as a means to foster problem solving through manufacturing.

The Science Castle Grant THK Prize for children working on research development in manufacturing was also renamed to the "Science Castle THK First Step in Manufacturing Prize" last year. Of the 36 schools that applied, 10 were selected to receive support for their development activities from THK employees acting as engineering mentors over a period of six months. The gathering in December to present everyone's results was a lively and energetic event. The students presented on their research with determined expressions, answered questions from the judges, and listened earnestly to the presentations from the other teams. The program has been growing, with one past winner of the Best Development Prize, Okayama Junior High School, winning a prize at the Japan Student Science Awards and receiving media coverage.

We will continue our outreach program next year and beyond, and in addition to maintaining our THK First Step in Manufacturing Prize, we plan to expand manufacturing education materials designed for middle school engineering and home economics courses throughout all of Japan.

Below is a list of the schools and research projects that have previously received the Science Castle Grant THK Prize for Best Development.

| 2018 winner | |

|---|---|

| 2019 winner | |

| 2020 winner | |

| 2021 winner |

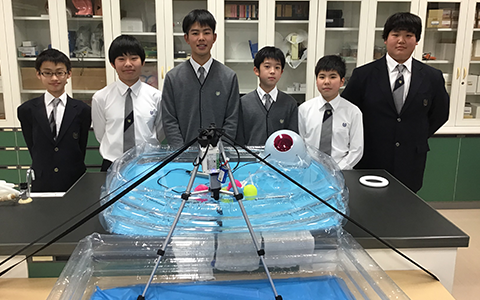

Science Castle Grant THK Prize Winner: Seiko Gakuin High School

We are grateful for the opportunity to present the results of our research at Science Castle. We are also proud that we won the THK Prize for using the LM Guide as the subject of our research to experiment and develop our own solution for a challenge faced by society.

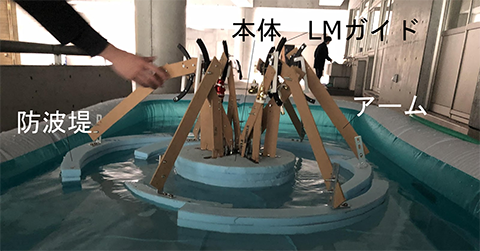

First, we discussed different social challenges the world is facing. We concluded that every problem-energy problems, food shortages, and overpopulation-stems from a lack of land. We focused on effectively using the ocean, which we cannot say has been utilized enough. We felt we could use the ocean for more land to solve the land shortage and showcase Japan's advanced technology to the world.

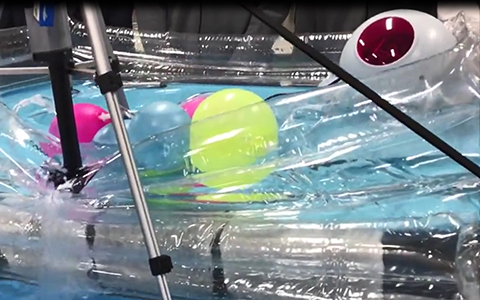

Our plan is to create artificial islands and install the Curved Guide on the floating structures that surround the island to absorb the rocking from the push and pull of the waves. When we created a small model, placed it in an acrylic pool, and measured the movement caused by the waves we generated, we found that the rocking of the floating surfaces was somewhat absorbed (see photo).

Our experiment is still ongoing. Even if it is not much, we hope to see satisfying results by continuing to go through trial and error and repeated experimentation next year.

Higashi-Katsushika High School: Winner of the Science Castle Grant THK Prize for Best Development

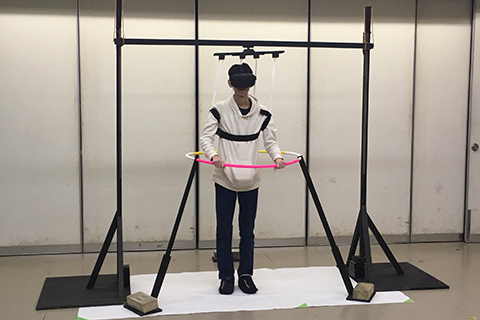

In October 2018, we participated in a work-study program at a general hospital near our school, and we saw many patients going through physical therapy. In response to the future aging of our society, we thought we could reduce healthcare costs if patients would be able to comfortably recuperate at home, so we challenged ourselves to come up with our own walking rehabilitation device. To motivate people to do their exercises by showing them pleasant scenery so they are not just walking in place, we took inspiration from old movies, especially memorable Spielberg films, and decided to use VR.

Our initial concept was to use the motion of the LM Guide to achieve movement in all four directions as well as rotary motion, but we were not successful. We intended to present a device that supports the waist at our school festival in September 2019, but even though we only put up a poster, there was a big response. That gave us the confidence to develop a new device, and we settled on our current mechanism (see photo). An LM Guide is installed on the support columns for both arms, which are used for squatting motions. When the user crouches, the elasticity of the rubber returns them to their original position. The LM Guide enables the bar to move smoothly, which drastically reduces the stress on the hips and knees.

Development is still ongoing as we work to accurately link the user's movements with the VR. We are considering the design from the patient's point of view to investigate ways to make this device more pleasant to use.

Winner of the Science Castle Grant THK Prize for Best Development: Okayama Junior High School (Okayama City)

Seeing the 2018 floods damage our friends' houses and watching the rescue teams saving people from the widespread flooding downtown after the levees collapsed made us realize our limitations. That is how we came up with the concept of creating a disaster prevention robot to minimize damage immediately after a levee collapses.

We named it the Megaslime 39. First, it uses an air pump to cause balloons to float, then an electromagnetic valve is used to release the air so the balloons can be filled with water. After that, a submersible pump adds the water so the balloons will sink from the weight of the liquid. The six water-filled balloons then plug the space where the river has broken its bank. The current robot is a miniature, indoor model. Because the battery runs out quickly and it cannot be used outside of the remote control range, it is 70% complete. However, we should make a breakthrough if we can come up with solutions like adding a solar cell to keep it from losing power or putting a cellphone inside the robot to operate it remotely by using the electric current from when the phone produces sound.

When we started on this project, we were unsure if we would be successful, but our advisor supported us over those six months and gave us very reassuring advice whenever we ran into trouble. Because of the pandemic, we ran into issues with the audio and frozen screens when meeting online, but we ended up with an amazing creation. There are big challenges ahead, but we hope to see this disaster prevention robot in action.

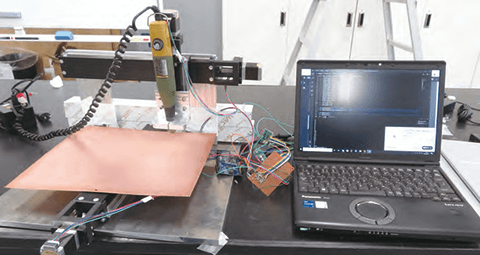

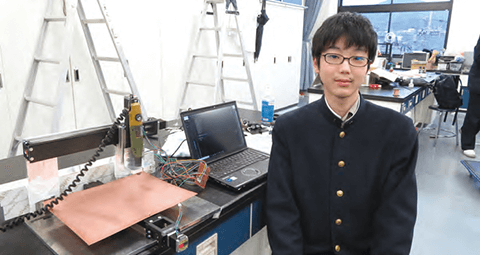

Rakusei Senior High School (Kyoto): Winner of the Science Castle Grant THK Prize for Best Development

Project to Develop a Desktop Circuit Board Manufacturing Device

As part of the robot research club, I research engineering topics that I am interested in, which includes creating robots and programs. In June 2021, I participated in RoboCupJunior Worldwide and won in the Rescue League, which is a contest of accuracy and speed as autonomous robots search for victims inside a maze that simulates a disaster site. The process of making printed circuit boards for the tournament was inconvenient, so when I was working on developing a device that could make them more easily, I wanted to get a professional engineer's feedback on the design, so I applied for a Science Castle grant.

Normally, you use an etching solution to dissolve the copper plating on a circuit board and make the circuit, but that produces liquid waste, so I went with a method where you cut the circuit board with the copper plate attached and you do not have to do any waste liquid treatment. The device uses a dental drill that is moved in all directions by LM Guide units. I am very close to being able to process one side of the circuit board, but I want to be able to create two-sided circuit boards for robots. An engineering mentor from THK gave me advice about controlling systems with actuators and other tips.

In the future, I want to study engineering and do research that will solve the problems people face in their daily lives. I have not narrowed down exactly what I want to do yet, but I hope that my research will get more people involved in manufacturing and help contribute to the development of industry in Japan.

Charitable Contributions

As part of our contributions to society, we provide financial assistance in times of natural disasters and donate money to organizations devoted to the advancement of science and the future development of manufacturing in Japan.

| Date | Purpose | Recipient |

|---|---|---|

| 2023/1/1 | Japan Science Foundation support/membership dues | Japan Science Foundation |

| 2023/2/1 | 2023 Türkiye-Syria Earthquake Relief Fund | Japanese Red Cross |

| 2023/3/1 | April 2023 to March 2024 membership dues | Japan Overseas Educational Services |

| 2023/3/1 | 2023 Türkiye-Syria Earthquake Relief Fund (Wuxi and Changzhou plants) | China Charity Federation |

| 2023/4/1 | Japan Philharmonic Orchestra annual special member fee (corporate donation) | Japan Philharmonic Orchestra |

| 2023/8/1 | June 30, 2023, Heavy Rain Disaster Relief | Japanese Red Cross |

| 2023/8/1 | July 7, 2023, Heavy Rain Disaster Relief | Japanese Red Cross |

| 2023/8/1 | Activity funds | Japanese Red Cross |